What Is CNC Machining? A Complete & Practical Guide

In today’s manufacturing landscape, CNC Machining (Computer Numerical Control) is the bedrock of precision engineering. From the titanium frame of a fighter jet to the aluminum casing of your MacBook, CNC powers the modern world.

But for many engineers and procurement managers, CNC machining is often treated as a “black box”: you send a CAD file in, and a part comes out.

At CNMP, we believe understanding what happens inside that box is the key to designing better parts and reducing costs. This guide pulls back the curtain, combining the theoretical knowledge of our Materials Scientists with the gritty reality of our Shop Floor Managers.

1. The Core Principle: “Controlled Subtraction”

At its simplest, CNC machining is a Subtractive Manufacturing process. It starts with a solid block of material (the “blank”) and removes material using rapidly rotating tools or stationary cutters until the final shape is revealed.

The Materials Scientist’s View (The Physics): “Think of CNC machining as managing Shear Stress. We are forcing a cutting tool—which must be harder than the workpiece—to shear off layers of metal. This generates immense heat and localized stress. If we cut too fast, the heat changes the metal’s temper (ruining a T6 heat treat). If we cut too slow, the tool rubs and work-hardens the surface.”

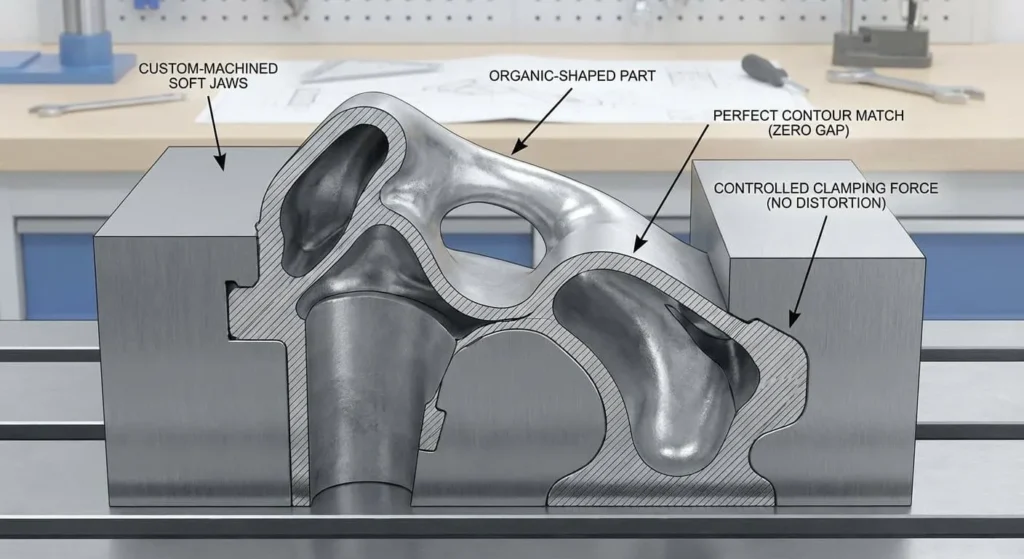

The Shop Floor Manager’s View (The Reality): “I call it ‘Controlled Violence.’ We are driving a carbide cutter into a block of steel at 10,000 RPM. The machine must be incredibly rigid. If the workpiece vibrates even slightly (chatter), the tolerance is gone. Achieving ±0.005mm isn’t just about the computer code; it’s about how tightly we can hold the part without crushing it.”

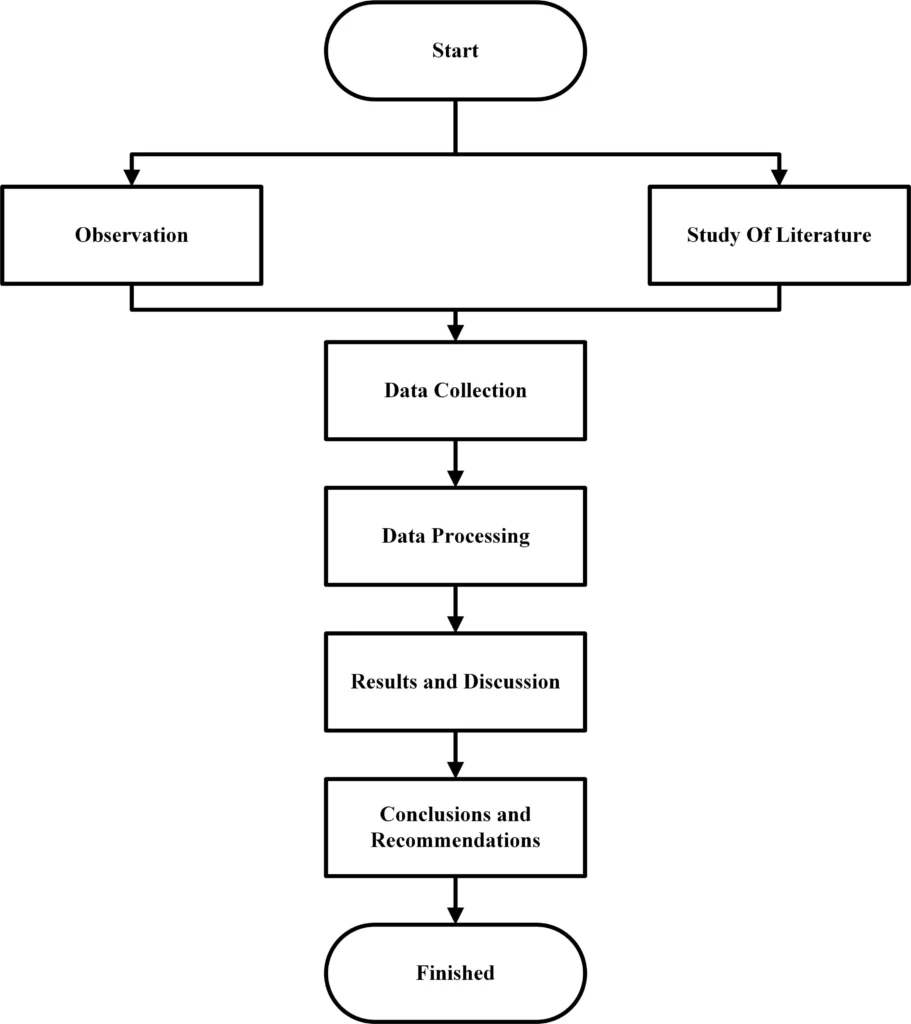

2. The CNC Workflow: From Art to Part

How does a digital design become a physical object? Here is the lifecycle of a CNMP part.

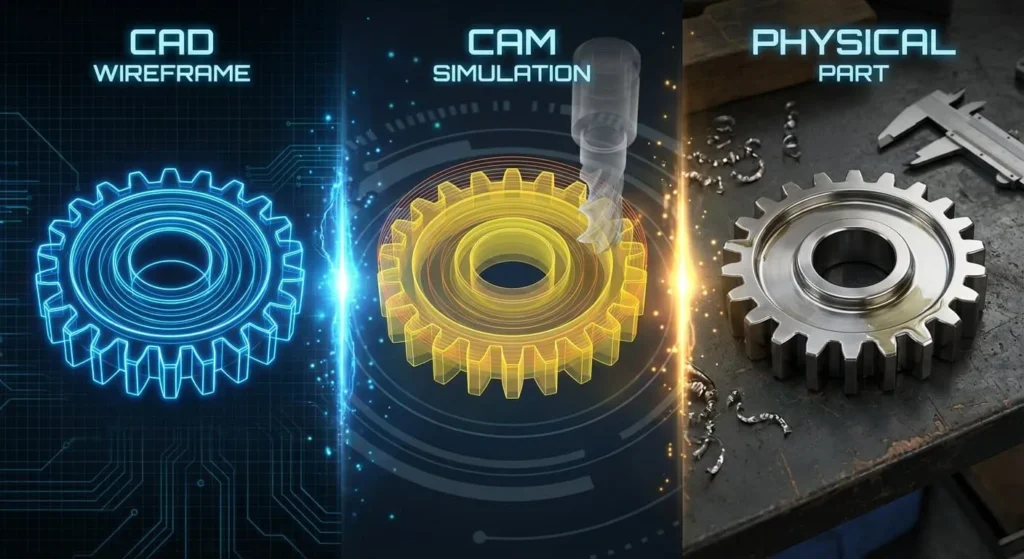

Step 1: The CAD Model

Everything begins with a 3D design. This is the blueprint.

Step 2: CAM Programming (The “Brain”)

We don’t just load the model into the machine. We use CAM (Computer-Aided Manufacturing) software to generate G-Code.

- The Scientist: “This is where we define the chip load—how thick each cut is. This determines the thermal load on the material.”

- The Machinist: “This is where we prevent crashes. I simulate the tool path to ensure the tool holder doesn’t slam into the clamps. A bad programmer can destroy a $500,000 machine in milliseconds.”

Step 3: Setup & Fixturing (The Unsung Hero)

The Machinist: “This is the most underappreciated step. How do you hold a round, organic shape like a computer mouse shell? You can’t use a standard vise. We often have to machine Soft Jaws—custom aluminum clamps that mirror the part’s shape. Rigidity is everything.”

Step 4: Execution & Machining

The machine executes the G-Code. This may involve Milling, Turning, or Drilling.

Step 5: Inspection & Finishing

Once cut, the part isn’t done. It goes to QC for CMM (Coordinate Measuring Machine) verification, then to finishing.

Internal Link: Confused about finishing options? Read our Ultimate Guide to Surface Finishes: Function & Aesthetics.

3. Types of CNC Machines: Picking the Right Tool

Not all CNC machines are created equal.

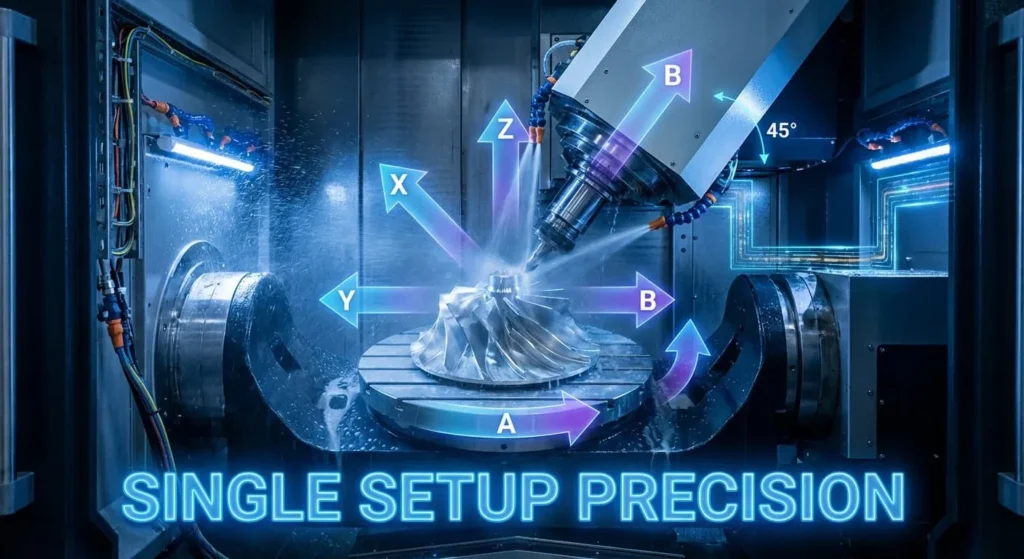

CNC Milling (3-Axis vs. 5-Axis)

- 3-Axis: The tool moves in X, Y, and Z. Great for flat parts.

- 5-Axis: The table or head rotates/tilts.

- Expert Insight: “People think 5-Axis is just for complex aerospace shapes. Wrong. We use 5-Axis to save time. If a part needs holes on 5 different sides, a 3-Axis machine requires 5 manual setups. A 5-Axis machine does it in ONE setup. This improves accuracy because we never lose the ‘Zero Point’.”

CNC Turning (Lathes)

The workpiece spins, and the tool is stationary. Ideal for cylindrical parts.

- Expert Insight: “For high-volume small parts (like pins or screws), we use Swiss Lathes. They use a guide bushing to hold the material right next to the cutter, eliminating deflection.”

4. Materials: The Foundation of Quality

CNC machining supports almost any material that is hard enough to be clamped.

- Aluminum: The industry standard.Internal Link: Dive deep into 6061 vs 7075 in our Bible of CNC Aluminum Grades.

- Metals: Stainless Steel, Carbon Steel, Titanium, Copper, Brass.Internal Link: Need to choose between Brass and Copper? Check our Comprehensive Material Selection Guide.

- Plastics: POM (Delrin), PEEK, Nylon, Polycarbonate.

5. CNC Machining vs. 3D Printing: The Honest Comparison

We often get asked: “Why not just print this?”

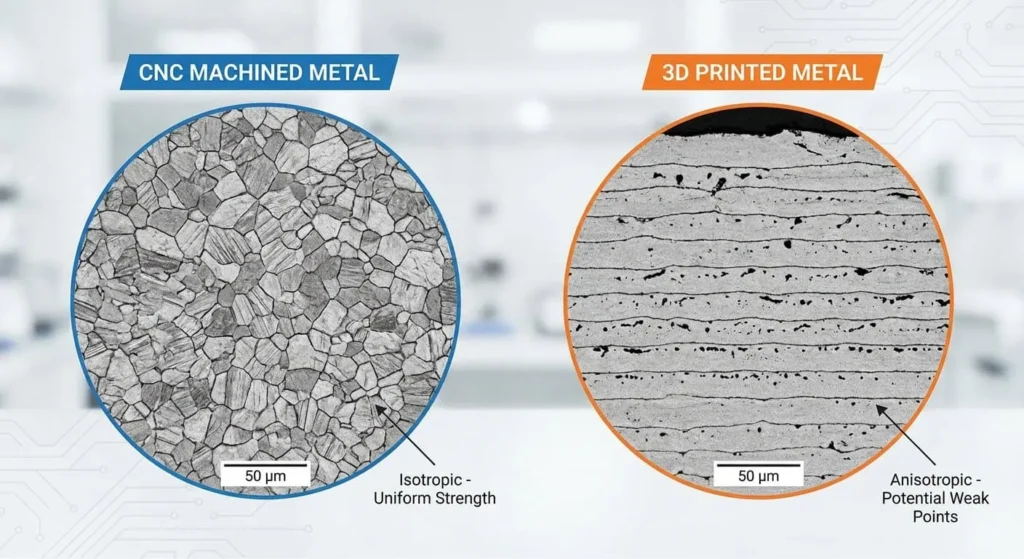

The Materials Scientist’s Verdict: Isotropy “The biggest difference is structural integrity.

- CNC Machining Parts are Isotropic: They are cut from a rolled or forged billet. The material strength is uniform in all directions (X, Y, and Z).

- 3D Printed Parts are Anisotropic: They are built in layers. They are strong in X/Y but inherently weak in the Z-axis (layers can de-laminate). Verdict: For functional, load-bearing, or structural parts, CNC machining is still the king.”

The Shop Floor Verdict: Precision “I can hold a ±0.01mm tolerance on a CNC mill all day long. On a standard 3D printer? You are lucky to get ±0.1mm. Plus, the surface of a machined part is smooth metal; a printed part looks like a stack of pancakes.”

6. Limitations: When NOT to use CNC

We want your business, but only if it makes sense. CNC is not magic.

- Cost: It is generally more expensive than 3D printing for single prototypes due to setup time.

- Geometry: You cannot machine internal 90-degree corners (because the tool is round) or hollow complex lattices (the tool can’t reach inside).

- Waste: It removes material. Machining a small bracket from a giant block creates 80% waste chips.

Conclusion: Start Your CNC MachiningJourney

CNC machining is the perfect blend of digital precision and mechanical craftsmanship. It enables the creation of parts that are strong, precise, and beautiful.

Whether you need a single AL6061-T6 prototype or 10,000 Stainless Steel 304 production parts, the key is working with a partner who understands the science behind the cut.

Ready to start?

- Upload your CAD file for an instant DFM review.

- Contact CNMP to speak with our engineering team.