The Ultimate Guide to 5-Axis CNC Machining: Process, Costs, and Design Secrets

By The CNMP Expert Team

In the modern manufacturing landscape, complexity is the new normal.

Aerospace engineers are designing organic, lightweight frame structures. Medical companies are modeling implants that perfectly match the curvature of human bone. Energy sectors require impellers with blade geometries that seem mathematically impossible.

If you try to manufacture these parts on a standard 3-axis mill, you hit a wall. You are forced to flip the part 5, 6, or even 10 times. Every flip kills your tolerance. Every new fixture drains your budget.

Enter 5-Axis CNC Machining.

It is often called the “Formula 1” of the machining world. It is fast, precise, and expensive. But it is also misunderstood. Many engineers believe it is only for aerospace, or that it is always more expensive than 3-axis. Both are myths.

In this comprehensive guide, we strip away the marketing hype. We will explore the physics of 5-axis motion, compare the different machine architectures (Trunnion vs. Swivel Head), and reveal how this technology can actually lower your total production cost through the power of “Done-in-One.”

What Exactly is 5-Axis CNC Machining?

Beyond X, Y, and Z.

To understand the power of 5-axis, we must first look at the limitations of standard machining.

- 3-Axis Machining: The tool moves in three linear directions: X (Left-Right), Y (Forward-Back), and Z (Up-Down). The tool always points straight down. It cannot reach the side of a cube without you manually turning the cube over.

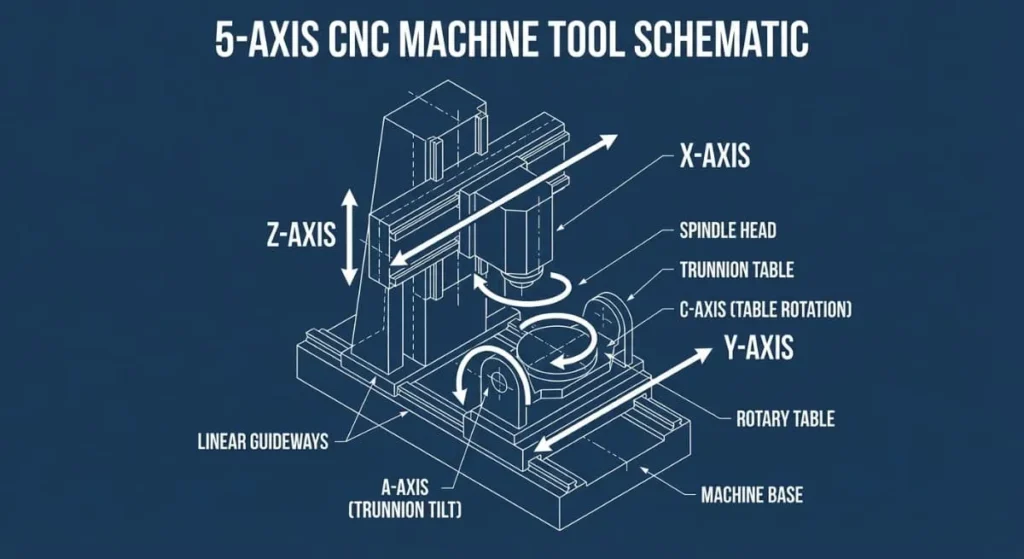

5-Axis CNC Machining adds two Rotary Axes to this equation. These axes allow the cutting tool to approach the workpiece from almost any vector.

The standard naming convention for these rotary axes depends on the machine, but typically:

- A-Axis: Rotation around the X-axis (Tilting).

- B-Axis: Rotation around the Y-axis (Tilting).

- C-Axis: Rotation around the Z-axis (Spinning like a record player).

By combining linear motion (XYZ) with rotary motion (A, B, or C), the machine can machine 5 sides of a prismatic part in a single setup, or sculpt complex freeform surfaces continuously.

Machine Architectures: Trunnion vs. Swivel Head

Not all 5-axis machines are built the same.

When you send a quote to a machine shop, it helps to know what kind of hardware they are running. There are two main types of 5-axis CNC machining centers, each with its own strengths.

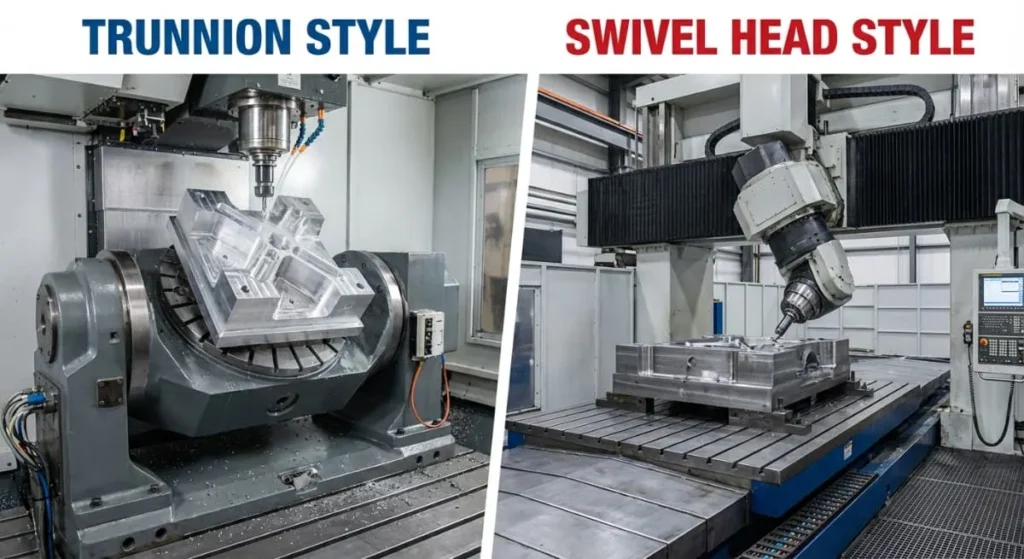

1. Trunnion Style (Table-Table)

- How it works: The spindle (tool) stays stationary (vertical), while the table moves. The table tilts (A-axis) and rotates (C-axis).

- The Look: Imagine a cradle rocking a baby. The part sits inside this cradle.

- Pros: Extremely rigid. Better for heavy cutting and hard metals like Titanium and Stainless Steel.

- Cons: Limited part size. The part must fit inside the cradle swing.

- Best For: Small to medium precision parts, medical implants, impellers.

2. Swivel Head Style (Head-Table)

- How it works: The table rotates (C-axis), but the spindle head tilts (B-axis). The tool itself angles around the part.

- The Look: The cutter head articulates like a human wrist.

- Pros: Can handle massive, heavy parts because the table doesn’t need to tilt the weight of the part.

- Cons: Slightly less rigid than a trunnion.

- Best For: Large aerospace frames, automotive molds, huge engine blocks.

Expert Insight:

“At CNMP, we utilize both types. We put your small medical parts on our high-speed Trunnions and your large aerospace bulkheads on our Swivel Head gantries.”

The Critical Distinction: Simultaneous vs. 3+2

Ranking Factor: The most important concept for buyers.

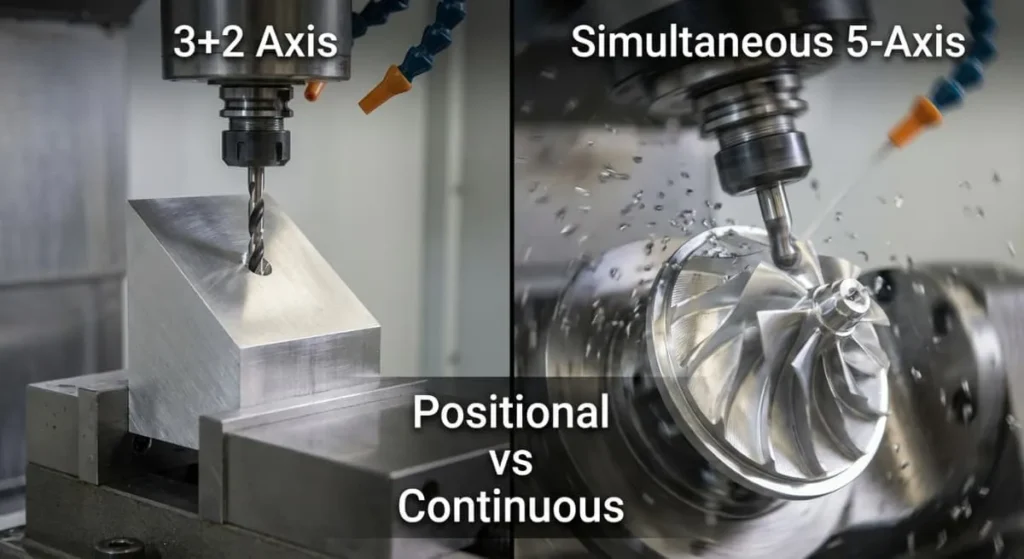

This is the source of 90% of the confusion in the industry. Just because a machine has 5 axes doesn’t mean it uses them all at once.

1. 3+2 Axis cNC Machining (Positional)

- Also known as: 5-Axis Indexing.

- The Process: The machine tilts the part to a fixed angle (Axis 4 and 5), locks the brakes, and then machines using only X, Y, and Z.

- The Analogy: It’s like an artist adjusting their easel to a better angle, locking it in place, and then painting.

- Why use it? It allows standard 3-axis strategies (like flat end mills) to be used on angled faces. It is extremely rigid and easy to program.

- Application: Gearboxes, valve manifolds with holes on multiple sides.

2. Simultaneous 5-Axis CNC Machining (Continuous)

- The Process: All 5 axes move dynamically at the same time. The tool vector changes constantly as it moves across the surface.

- The Analogy: It’s like a sculptor walking around a statue while chiseling it, never stopping.

- Why use it? It is the only way to machine curved surfaces where the tool must stay normal (perpendicular) to the surface.

- Application: Turbine blades, impellers, anatomical bone shapes, aerodynamic profiles.

The “Hidden” Engineering Benefits

Why 5-Axis makes better parts, faster.

Most people think 5-axis CNC machining is just for making “cool shapes.” But the real engineering value lies in Efficiency and Quality.

1. Single Setup Accuracy (The GD&T Killer)

In traditional machining, every time you unclamp a part and flip it to machine the other side, you lose precision.

- 3 Axis Error: Flipping a part 6 times can result in a cumulative tolerance error of ±0.05mm.

- 5-Axis Solution: Because the machine can reach 5 sides in one hold, the relative position between Feature A (Top) and Feature B (Side) is virtually perfect. This is critical for GD&T requirements like True Position and Perpendicularity.

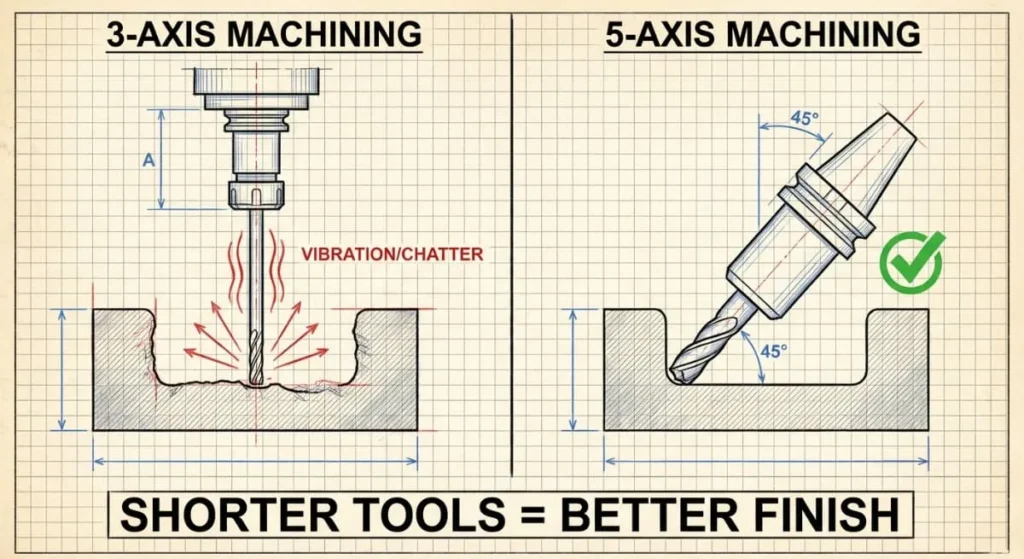

2. Shorter Tools = Better Surface Finish

This is a matter of physics.

- The 3 Axis Problem: To machine a deep cavity or reach over a tall wall, you need a long cutting tool. Long tools vibrate (chatter). Vibration causes rough surfaces and breaks tools.

- The 5-Axis Solution: We can tilt the toolholder away from the wall. This allows us to use a shorter, stouter cutter.

- The Result: Higher cutting speeds, zero vibration, and a mirror-like surface finish (Ra 0.4 – 0.8μm) right off the machine.

3. Complex Scallop Height Control

When machining a curved surface with a ball-nose end mill, the tool leaves small ridges called “scallops.”

- In 3 Axis: The tool tip (where rotation speed is effectively zero) drags across the surface, leaving poor finish.

- In 5-Axis: We can tilt the tool slightly so the side of the ball mill cuts the material. This keeps the cutting speed high and the surface smooth.

The Economics: Is 5-Axis CNC Machining Worth the Cost?

This is the most common objection we hear: “Isn’t 5-axis expensive?”

The short answer is: Yes, the hourly rate is higher. A 5-axis machine costs significantly more to buy and maintain than a 3-axis mill. However, looking at the hourly rate alone is a rookie mistake. You must look at the Total Cost of Production.

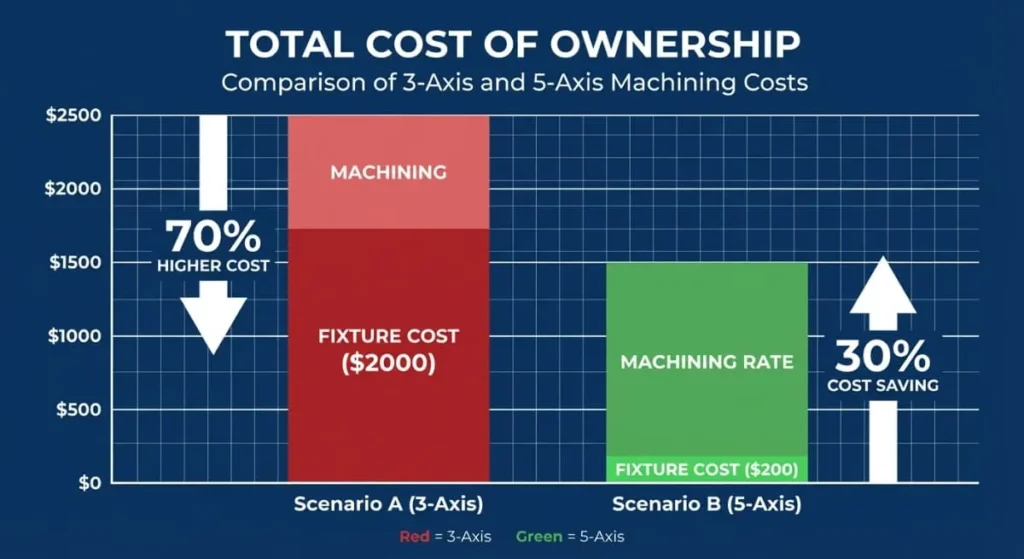

Let’s break down the math for a complex Aluminum Housing (50 units):

Scenario A: The 3-Axis Way (The “Old School” Method)

- Machine Rate: $80/hour.

- Setups Required: 6 (Top, Bottom, Front, Back, Left, Right).

- Fixtures Needed: 4 custom jigs ($2,000 total).

- Operator Time: High (Loading/Unloading 6 times per part).

- Risk: High probability of scratch marks or misalignment during flipping.

- Total Time: 3 weeks (due to fixture fabrication).

Scenario B: The 5-Axis Way (The Efficient Method)

- Machine Rate: $120/hour (Higher rate).

- Setups Required: 2 (Op 1: Do 5 sides; Op 2: Remove excess material).

- Fixtures Needed: 1 standard dovetail fixture ($200).

- Operator Time: Low (Load once, walk away).

- Risk: Near zero.

- Total Time: 5 Days.

The Verdict:

While the hourly rate is 50% higher, the Total Project Cost for the 5-axis option is often 20-30% lower because you saved thousands on fixtures and weeks of lead time.

Rule of Thumb:

If your part needs to be touched on more than 3 sides, 5-Axis CNC Machining is usually the cheaper option.

DFM Guide: Designing for 5-Axis Success

How to design parts that don’t fail.

Just because the machine can move in 5 axes doesn’t mean it can do magic. Physics still applies. To get the best results from CNMP, follow these design rules:

1. Tool Reach & Clearance

The spindle housing is bulky. As the machine tilts to reach a deep corner, the head might collide with the table or the part.

- Tip: Keep deep pockets wide enough for the tool holder to clear the walls when tilted.

- Tip: Use shorter tools where possible. The machine can tilt to help, but standard tools (like end mills) typically have a length-to-diameter ratio of 3:1 or 5:1.

2. Workholding (The Dovetail)

How do we hold a part if we need to machine 5 sides of it? We can’t use a standard vise (it would block the sides).

- The Standard Method: We usually machine a small “Dovetail” or “Preparation Stock” on the bottom of your raw material. The 5-axis machine clamps onto this bottom 3mm of material.

- Design Note: Please allow for extra raw material stock (usually 5-10mm) at the bottom of your part for clamping, which will be machined off in the final operation.

3. Undercuts are still Tricky

Even with 5-axis, we cannot machine a “cave” inside a part. The tool still needs a line of sight.

- Check: Visualize the tool approaching the face. Is it blocked by another feature? If yes, we need a special “Lollipop Cutter” or it might be impossible.

Industry Applications: Who Needs This Technology?

Targeting High-Value Niches.

1. Aerospace (Turbine Blisks & Impellers)

- The Challenge: Thin, curved blades that overlap each other.

- The Solution: Simultaneous 5-Axis. The tool snakes between the blades, maintaining a constant angle to the surface to ensure aerodynamic perfection.

- Material: Often Titanium Grade 5 or Inconel.

2. Medical (Implants & Prosthetics)

- The Challenge: Organic shapes (femur bones, knee joints) that have no flat surfaces.

- The Solution: Continuous machining to match the CAD model of the patient’s anatomy perfectly.

- Material: Titanium Grade 23 or Medical Grade PEEK.

3. Automotive (Porting & Manifolds)

- The Challenge: Engine intake/exhaust ports that curve internally.

- The Solution: 5-axis CNC machining allows the tool to follow the centerline of the curved pipe, smoothing the gas flow path.

Summary: The CNMP Advantage

5-Axis CNC Machining transforms manufacturing from a “brute force” process into an elegant, precise art form. It allows us to:

- Machine Complex Shapes: Impellers, Turbines, Organic curves.

- Hold Tighter Tolerances: By eliminating multiple setups.

- Reduce Lead Times: “Done-in-One” speed.

At CNMP, we don’t just own 5-axis machines; we have the master CAM programmers to run them. Whether you need a single prototype or 1,000 flight-critical aerospace parts, we have the capacity.

Ready to upgrade your precision?

Stop designing around the limitations of 3-axis mills.

Contact CNMP or Upload Your CAD for a free 5-axis manufacturing analysis.