Custom CNC Machining Services: The Definitive Guide to Sourcing from China

Introduction

In the modern landscape of high-stakes product development, the ability to source precision components reliably is a competitive advantage. Whether you are an aerospace engineer validating a turbine design or a procurement manager scaling up production for automotive sensors, the demand for custom CNC machining services has never been higher.

However, for many Western buyers, the process of finding a partner who can translate digital designs into physical reality is fraught with challenges. Sourcing from overseas can often feel like navigating a minefield. You may have valid concerns about communication gaps, inconsistent tolerances that disrupt assembly lines, or the security of your intellectual property (IP).

These anxieties often stem from a lack of transparency. The reality is that the landscape of China machining services has evolved drastically over the last decade. China is no longer just a destination for low-cost, low-quality labor. Today, it represents the global standard for combining advanced 5-axis technology with a mature, integrated supply chain that offers scalability unavailable elsewhere.

This guide is written specifically for overseas B2B buyers who need custom CNC machining services capable of producing non-standard parts strictly according to drawings, with full process control and traceability. We will go beyond the basics, diving deep into pricing structures, material science, quality assurance protocols, and the critical engineering support that separates a vendor from a true partner.

1. Defining “Custom CNC Machining Services”

To make informed procurement decisions, we must first define what we are buying. “Custom” is often a buzzword, but in precision manufacturing, it has a strict definition.

At its core, custom CNC machining services refer to a subtractive manufacturing process where computer software controls factory tools and machinery to remove material from a solid block. Unlike additive manufacturing (3D printing) or forming (injection molding), machining is about precision removal to achieve a net shape.

What “True Custom” Means for B2B Buyers

For professional buyers, “custom” means the manufacturer is not selling off-the-shelf screws or standard fittings. A true provider of custom CNC machining services produces non-standard parts strictly according to your CAD drawings (STEP, IGES) and technical requirements.

If a supplier tries to push “standard solutions” or catalog parts when you have provided a specific engineering drawing, they are not a true custom manufacturer. Real custom service includes:

- Full Adherence to Prints: Compliance with GD&T (Geometric Dimensioning and Tolerancing) callouts.

- Material Integrity: Using the exact alloy specified (e.g., Al 7075-T6), verified by mill certificates.

- Batch Flexibility: The ability to move from a single prototype to low-volume pilot runs, and finally to mass production.

2. Core Technologies in Custom CNC Machining Services

Understanding the specific technologies used in custom CNC machining services allows you to communicate better with suppliers and optimize your designs for manufacturability (DFM).

CNC Milling Services: The Workhorse of Precision

CNC Milling is the backbone of most custom machining projects. In this process, the workpiece remains stationary (clamped to a bed) while high-speed cutting tools rotate to remove material.

- Applications: It is ideal for prismatic parts, complex contours, pockets, slots, and holes.

- Capabilities: Modern milling centers can handle everything from simple brackets to complex aerospace housings.

- Logo Machining: Milling is also the primary method for custom logo machining, where small-diameter tools are used to engrave branding directly into the metal.

CNC Turning Services: Rotational Symmetry

CNC Turning operates on a different principle: the workpiece rotates at high speed while a stationary cutting tool shapes it.

- Applications: This process is primarily used for cylindrical parts such as shafts, pins, bushings, sleeves, and spacers.

- Advantages: Turning provides superior concentricity and roundness compared to milling, and it generally offers faster cycle times for round parts.

5-Axis CNC Machining: Complex Geometries

For the most demanding projects, 5-Axis CNC Machining is the solution. The tool moves across five different axes simultaneously, allowing the machine to approach the workpiece from almost any angle.

- The Efficiency Factor: By machining complex geometries (like impellers or turbines) in a single setup, 5-axis machining reduces fixturing errors and significantly speeds up production.

- Cost Reality: Choosing between 3-axis and 5-axis isn’t just about capability; it’s about cost-efficiency. While 5-axis is powerful, a skilled manufacturer will tell you if your part can be made cheaper on a 3-axis machine.

3. The Strategic Advantage: Why Source from China?

There is a lingering misconception that “Made in China” implies lower quality. In the realm of precision engineering, this view is outdated. Top-tier China machining services now utilize the exact same advanced machinery (Haas, Mazak, DMG Mori) and inspection equipment (Zeiss CMM) as their Western counterparts.

The Integrated Supply Chain Ecosystem

China’s real competitive edge isn’t just labor cost; it is the complete CNC supply chain. In mature manufacturing hubs like Shenzhen or Dongguan, a factory is rarely working in isolation. They are supported by a dense network of:

- Tooling Suppliers: Providing cutters, inserts, and custom fixtures.

- Material Providers: Local availability of raw metals reduces logistics costs and lead times.

- Finishing Partners: Specialized heat treatment, anodizing, and plating services are readily available nearby.

This ecosystem allows custom CNC machining services in China to scale fast without the logistical nightmares found in fragmented supply chains.

Scalability and Flexibility

Many Western machine shops have rigid business models, preferring either high-volume orders or expensive, dedicated prototyping. Chinese factories are uniquely flexible. We can handle a single prototype unit today and scale to 10,000 units next month without needing to switch suppliers.

4. Material Selection: Optimizing for Performance and Cost

Your choice of material dictates not only the performance of the part but also the cost of the custom CNC machining services. A professional manufacturer will always offer a DFM review to suggest the best material for your application.

Aluminum Alloys

- Aluminum 6061 / 7075: These are the most popular choices for custom machining. They are lightweight, easy to machine, and anodize beautifully.

- Usage: Housings, brackets, drone parts.

Stainless Steel

- 303, 304, 316: Known for corrosion resistance and high strength. However, they are harder to machine, which increases cycle time and tool wear, leading to higher costs.

- Usage: Medical devices, food processing equipment.

Titanium

- Ti-6Al-4V: Offers an exceptional strength-to-weight ratio but is notoriously difficult to cut. Sourcing this requires a partner with specialized tooling strategies.

- Usage: Aerospace, high-performance automotive.

Engineering Plastics

- POM (Delrin) & PEEK: From rigid, low-friction POM to high-temperature PEEK, plastics can replace metal in many high-stress environments.

5. Pricing Breakdown: What Determines the Cost?

One of the most frequent searches by procurement managers is for custom cnc machining service pricing. The truth is, there is no flat rate. Pricing is a calculation based on machine time, complexity, and risk.

Here is the insider breakdown of what drives your costs up:

1. Machining Time & Material Removal

The longer the machine runs, the higher the cost. Removing large amounts of material from a block takes time. Smart design reduces the volume of material to be removed.

2. Tolerance Requirements

This is a major cost driver. Standard ISO 2768-m tolerances are cost-effective. Demanding ±0.005mm on every dimension requires specialized tooling, temperature control, and slower cutting speeds, which significantly increases the price.

- Pro Tip: To lower costs, ask yourself: Does this specific surface really need a tight tolerance, or does it just need to fit “in the air”? Relaxing non-critical tolerances is the easiest way to save money.

3. Complexity and Setups

A part that needs to be flipped and reset 4 times (multiple setups) costs more than a part done in one go. While 5-axis machining can reduce setups, the machine hourly rate is higher.

4. Surface Finishing

Standard “as-machined” is the cheapest option. Processes like polishing, bead blasting, or powder coating add extra steps and labor to the production line.

6. Quality Control: The Foundation of Trust (E-A-T)

In the B2B manufacturing world, Trust (a key part of Google’s E-A-T concept) is built on data, not promises. When sourcing custom CNC machining services, you need assurance that the part will fit.

The Quality Assurance Workflow

A reputable factory must adhere to strict quality standards, often evidenced by certifications like ISO 9001 and IATF 16949 (for automotive sectors).

- Incoming Material Inspection: We verify material certificates (Mill Certs) to prove the aluminum is actually 6061-T6, not a cheaper alloy.

- In-Process Inspection: Operators check parts during production to catch drift early.

- First Article Inspection (FAI): For volume orders, we send the first part for approval before running the full batch.

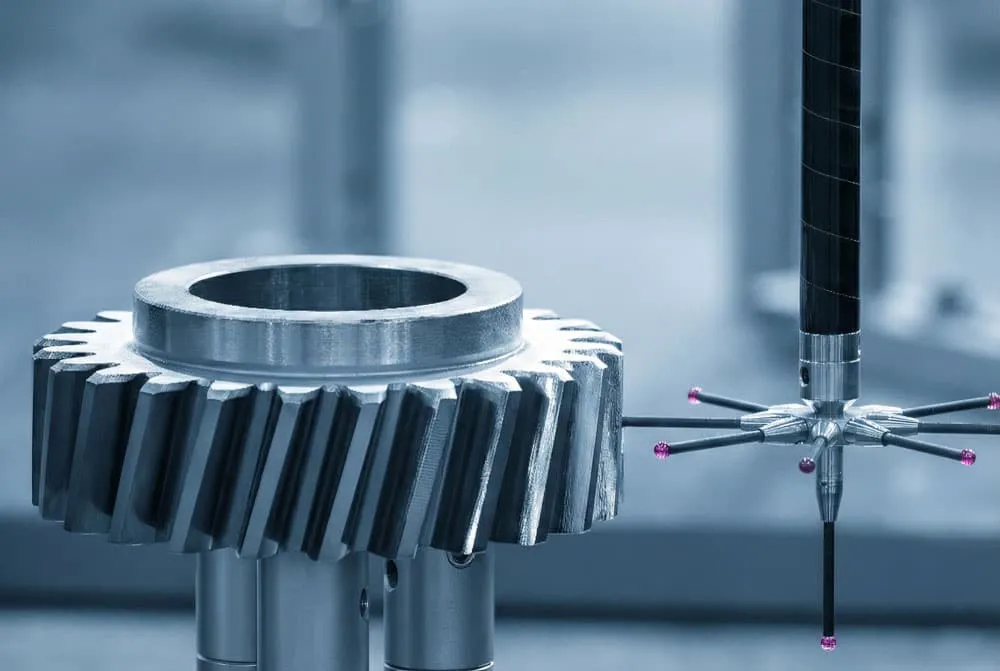

- Final QC with CMM: A Coordinate Measuring Machine (CMM) is used to verify complex geometries to micron-level accuracy.

Case Study: Precision Gears for UK Robotics

To illustrate our commitment to quality, consider a recent project. We worked with a UK robotics firm requiring H7 tolerance fits for a critical gear system. The client had previously faced issues with inconsistent bore sizes from other suppliers, leading to assembly failures.

By utilizing our Zeiss CMM and implementing a strict in-process gauging protocol, we validated every single bore against the H7 standard. We provided a full dimensional report with the shipment, which allowed the client to reduce their incoming inspection time by 80%. This case exemplifies how professional custom CNC machining services can solve complex engineering challenges.

7. Surface Finishing: Aesthetics and Functionality

A raw machined part often isn’t ready for the market. Whether you need protection from the elements or a premium look, surface finishing is critical.

- Anodizing (Type II & III): Essential for aluminum parts. It adds a hard, protective layer and allows for color customization.

- Passivation: Used for stainless steel to prevent rust and improve cleanliness, which is crucial for medical applications.

- Powder Coating: A durable, thick paint suitable for industrial equipment housings.

- Laser Engraving: If you are looking for the best cnc service for custom logo machining, ensure your supplier offers in-house laser marking. This allows for part serialization and branding without delaying shipment.

8. The Hidden Cost: Communication & Engineering Support

In offshore sourcing, poor communication is often the hidden cost that ruins projects. It leads to wrong tolerances, incorrect finishes, and delayed deliveries.

A professional provider of custom CNC machining services distinguishes itself through engineering support, not just sales talk.

- Engineering Clarification: We don’t just quote; we clarify. If a drawing has conflicting dimensions, we ask before we cut.

- Drawing Revision Control: We ensure we are working from the latest file version to avoid legacy errors.

- English-Speaking Technical Support: You should be able to discuss technical details directly with a team that understands engineering terms.

If a supplier cannot explain their machining strategy, they are likely just a trader, not a manufacturer.

9. Step-by-Step: How to Order Custom Parts

Ready to start? Here is the standard workflow for working with a professional China machining services provider:

- Prepare Your Files: We need 3D files (STEP/IGES) for programming and 2D PDFs for specifying tolerances and threads.

- Submit for Quote: Upload your files. A good supplier will respond within 24 hours.

- DFM Review: Look for a supplier who gives feedback. Example: “If you increase this radius from 0.5mm to 1mm, we can use a larger tool and save 15% on cost”.

- Production & Updates: During production, you should receive photos or videos of your parts being machined.

- Shipping: Most parts are shipped via DHL/FedEx International Priority, arriving in 3-5 days.

FAQ: Common Questions for Overseas Buyers

Q: What is the standard lead time for custom CNC machining services?

A: For prototypes (1-10 parts), we typically ship in 3-5 days. For low-volume production (100-500 parts), it usually takes 10-15 days depending on finishing requirements.

Q: How do you protect my intellectual property (IP)?

A: We take IP seriously. We are happy to sign a Non-Disclosure Agreement (NDA) before you send any drawings. Your files are stored on secure, offline servers and are only accessible to the engineers working on your project.

Q: Do you offer assembly services?

A: Yes. Beyond custom CNC machining services, we can install Helicoil inserts, assemble mating parts, and package products in custom retail boxing.

Q: What if the parts do not meet the drawing specifications?

A: If the error is ours, we remake the parts immediately at no cost to you, or offer a full refund. Our business relies on long-term relationships, not one-off wins.

Conclusion: Choosing a Partner, Not Just a Vendor

Navigating the world of global manufacturing can be complex, but finding the right partner shouldn’t be. Custom CNC machining services are the bridge between your digital design and a physical, functional reality.

By choosing a professional China machining services provider, you gain access to world-class equipment, vast material options, and a cost structure that allows your business to scale competitively. The real difference is not geography—it’s the engineering mindset, process control, and communication discipline.

Whether you need a single complex prototype or a thousand production units, the key is transparent communication and strict quality control. Your parts deserve more than just machining; they deserve engineering responsibility.

Ready to bring your designs to life?

Stop guessing about costs and feasibility.

[Upload your drawings here for a Free DFM Review] and let our engineers optimize your parts for production. Contact us today to experience the difference professional custom CNC machining services can make.