The Definitive Guide to CNC Material Selection: Balancing Science & Manufacturability

By The CNMP Expert Team

Choosing the right material is arguably the most critical step in the product development lifecycle. A material might look perfect on a datasheet (high tensile strength, thermal resistance), but if it wreaks havoc on the shop floor, your costs will skyrocket, and lead times will drag.

At CNMP, we bridge the gap between the lab and the lathe. This guide breaks down the 7 Major Material Families used in precision CNC machining, analyzing specific grades through two distinct lenses:

- The Materials Scientist: Focused on Microstructure, Strength (Yield/Tensile), and Environment.

- The Machining Expert: Focused on Chip Formation, Tool Wear, and Cycle Time.

1. Aluminum Alloys: The King of CNC Material

Lightweight, versatile, and generally easy to machine. But which grade?

Want a deeper dive into Aluminum? Read our Bible of CNC Aluminum Grades.

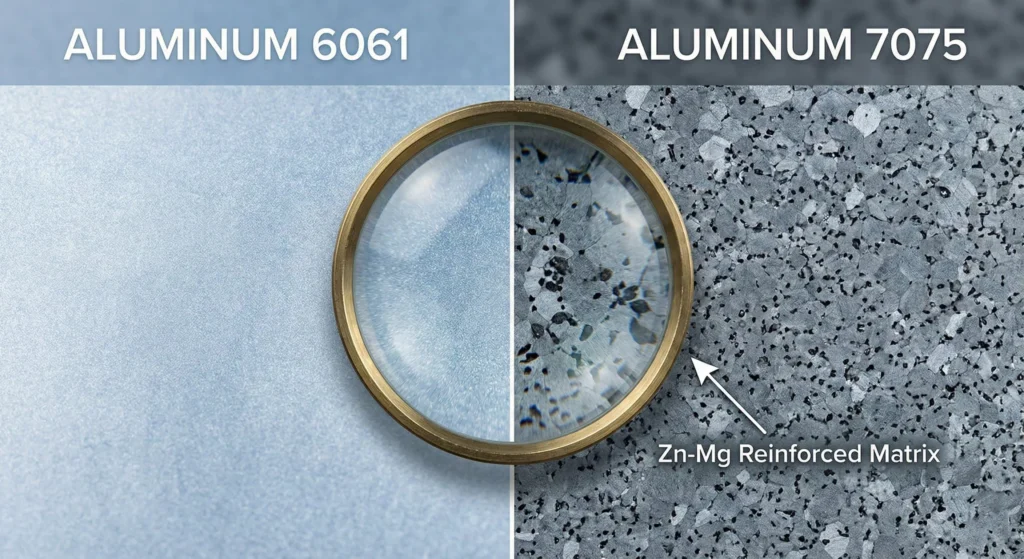

| Grade | Common Name | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| 6061-T6 | The Standard | Mg+Si. Balanced strength (276 MPa), corrosion resistance, and excellent weldability. The default choice. | Rating: 5/5. Breaks into consistent chips. Standard feeds and speeds apply. | Brackets, drone frames, electronics housings. |

| 7075-T6 | Aircraft Grade | Zinc. Extremely high strength (503 MPa), rivaling mild steel. High fatigue resistance. | Rating: 4.5/5. Machines “crisper” than 6061. Less gummy, creating a superior surface finish, but wears tools slightly faster. | Aerospace structures, high-stress gears, rock climbing gear. |

| 6063-T6 | Architectural | Surface Optimized. Smoother grain structure tailored for cosmetic anodizing. Slightly weaker than 6061. | Rating: 3/5. Gummy. Requires sharp tools to avoid “smearing.” Perfect for visual parts, tricky for tight tolerances. | Heatsinks, visible architectural trim. |

| 5052-H32 | Sheet Grade | Magnesium. Highest strength non-heat-treatable alloy. Exceptional saltwater resistance. | Rating: 2/5. Designed for bending, not cutting. Very stringy/gummy. Drilling leaves massive burrs. | Marine panels, fuel tanks, sheet metal enclosures. |

| MIC6 | Cast Plate | Stress-Relieved. Cast structure means zero internal stress. Stays dead flat after machining. | Rating: 4/5. Chips are powdery (like cast iron). Careful with threads (they strip easily). | Inspection fixtures, base plates, reference surfaces. |

2. Stainless Steels: The Cost of Corrosion Resistance

The most common source of “Over-Specifying” mistakes.

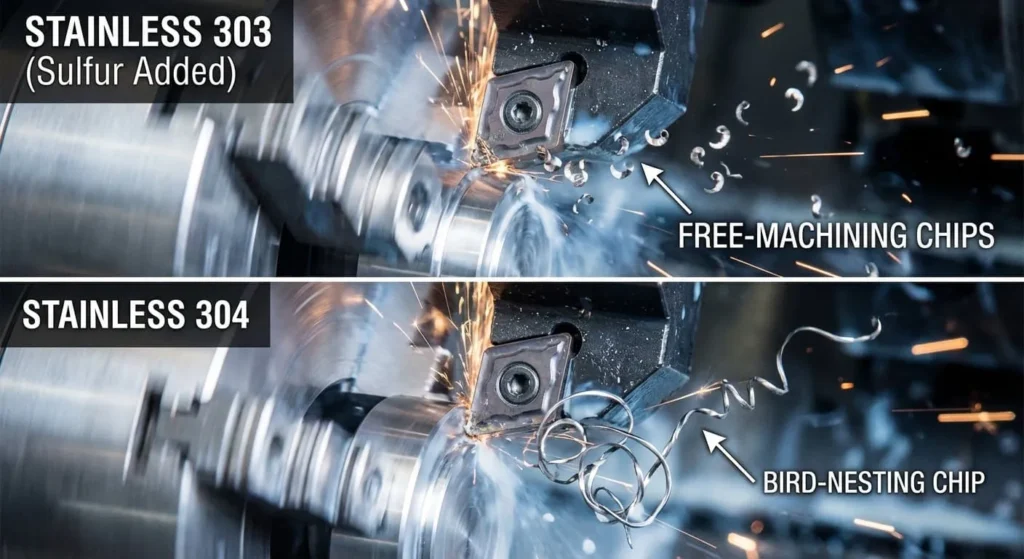

| Grade | Type | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| 303 | Free-Machining | Sulfur Added. The sulfur disrupts the metal matrix to break chips. Slightly less corrosion resistant than 304. | Rating: 4.5/5 (for SS). Machines 30% faster than 304. Tool life is doubled. Warning: Cannot be welded. | Bolts, shafts, fittings, non-welded medical parts. |

| 304 (L) | The “18/8” Classic | Chromium-Nickel. Excellent toughness and corrosion protection. The global standard. | Rating: 2.5/5. Work-hardens instantly. If the tool rubs, the surface glazes over. Chips are long and stringy (bird-nesting). | Kitchen equipment, sanitary piping, outdoor enclosures. |

| 316 (L) | Marine Grade | Molybdenum Added. Resists chlorides and acids. Essential for marine/medical use. | Rating: 2/5. Tougher than 304. Requires rigid machines and premium carbide tools. Slow cycle times. | Implants, chemical processing, marine hardware. |

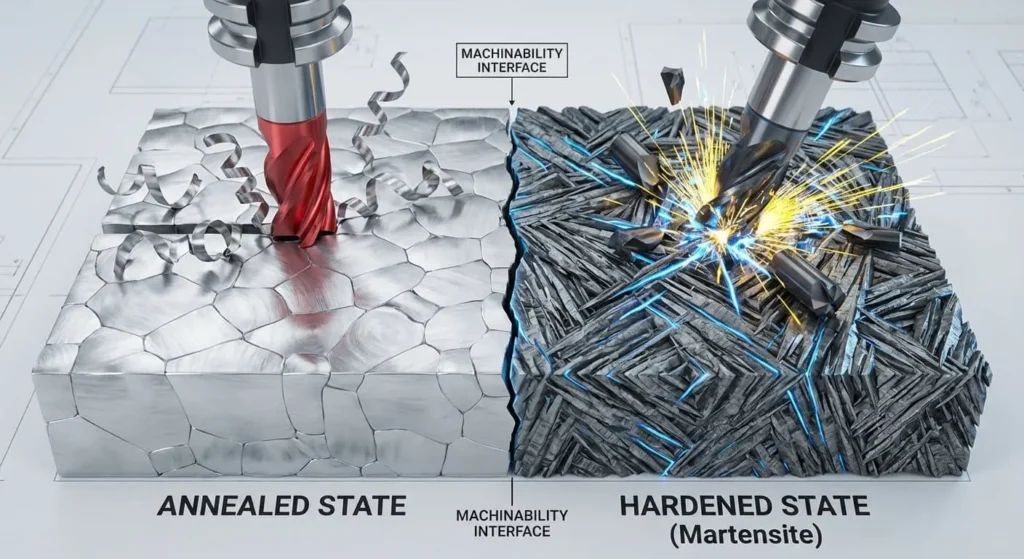

| 17-4 PH | Hard & Magnetic | Precipitation Hardening. Can be heat treated to HRC 40+. High strength + corrosion resistance. | Rating: 3.5/5. Surprisingly nice to machine in the annealed state. Clean finishes. Heat treat after machining. | High-load shafts, aerospace valves, turbine blades. |

3. Carbon & Alloy Steels: The Backbone of Industry

When you need raw strength and magnetic properties.

| Grade | Category | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| 1018 | Low Carbon | Ductile, easily welded, case-hardenable. Low cost. | Rating: 3/5. Can be “mushy” and tear. Hard to get a mirror finish without high surface speed. | Simple mounting plates, pins, brackets. |

| 1045 | Medium Carbon | Stronger and harder than 1018. Heat treatable. | Rating: 4/5. Cuts cleaner than 1018 due to higher carbon content. | Gears, axles, hydraulic rams. |

| 12L14 | Free Machining | Lead Added. Low strength, but breaks chips instantly. | Rating: 5/5. The fastest machining steel. Chips turn to dust. Self-lubricating. | High-volume standoffs, inserts, bushings. |

| 4140 | Chromoly Alloy | Cr+Mo. High fatigue strength and impact resistance. | Rating: 3.5/5. Often machined “Pre-Hardened” (HRC 30). Tough but predictable. Generates heat—use coolant! | Drive shafts, connecting rods, heavy-duty bolts. |

4. Tool Steels: The Hardest Workers

Used for making other parts (molds, dies, cutters).

| Grade | Type | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| A2 | Air Hardening | Good balance of wear resistance and toughness. | Machined Annealed (Soft). Once hardened (HRC 58+), requires EDM or Grinding. | Punches, dies, shear blades. |

| D2 | High Carbon/Chrome | Extreme wear resistance, but brittle. | Abrasive. Contains carbides that eat tool tips even in the soft state. | Stamping dies, slitting cutters. |

| O1 | Oil Hardening | General purpose, easy to heat treat. | Forgiving. Machines easily in annealed state. Less stable than A2 during heat treat. | Jigs, fixtures, gauges. |

5. Copper & Brass: Conductivity vs. Machinability

The “Golden” metals.

| Grade | Common Name | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| C360 | Free Cutting Brass | Cu+Zn+Pb. Excellent corrosion resistance. Heavy. | Rating: 5+/5. The dream material. Can run at max RPM. Tiny chips. Zero tool wear. | Fittings, decorative hardware, valves. |

| C101/110 | Pure Copper | 99.9% Cu. Highest electrical/thermal conductivity. | Rating: 1/5. A nightmare. Extremely “gummy.” Drills stick, taps break. Requires specialized polished tools. | Heatsinks, busbars, welding electrodes. |

| C145 | Tellurium Copper | Te Added. 90% conductivity of pure copper. | Rating: 4.5/5. The secret weapon. Machines like brass, conducts like copper. Use this if you can. | Electrical connectors, torch tips. |

| C932 | Bearing Bronze | SAE 660. Excellent friction properties and load bearing. | Rating: 4/5. Machines easily but chips are short and brittle. | Bushings, wear plates. |

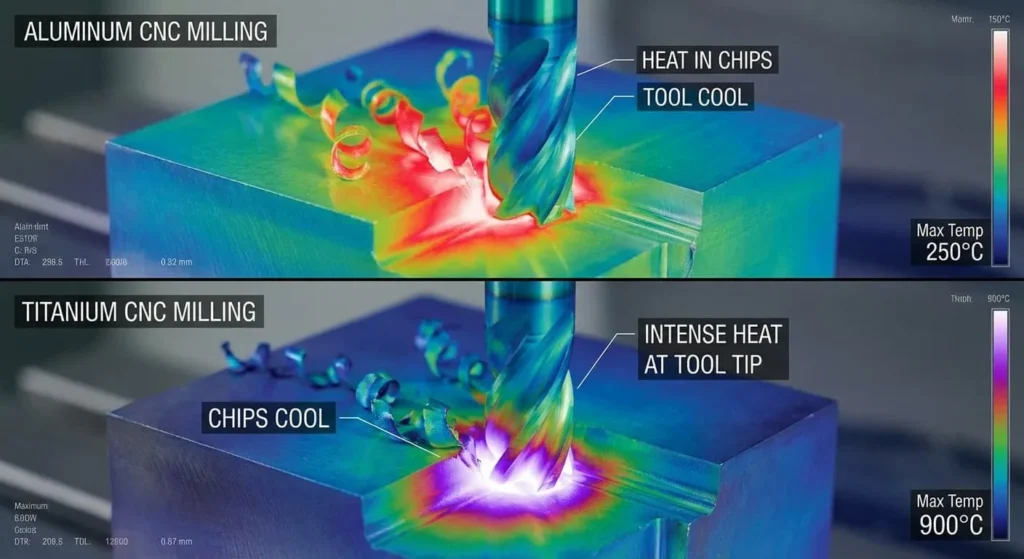

6. Titanium & Superalloys: The Aerospace Elite

High cost, high difficulty, high performance.

| Grade | Common Name | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| Ti-6Al-4V | Grade 5 Titanium | High strength-to-weight ratio. Biocompatible. Poor thermal conductor. | Rating: 2/5. “Springy.” Causes chatter. Heat stays in the tool, burning it up. Needs dynamic toolpaths. | Medical implants, aerospace structural parts. |

| Ti Grade 2 | Pure Titanium | Corrosion resistant, lower strength than Gr 5. | Rating: 1.5/5. Gummier than Grade 5. Tends to smear and gall. | Chemical processing, heat exchangers. |

| Inconel 718 | Superalloy | Nickel-based. Retains strength at 980°C. | Rating: 1/5. Work-hardens aggressively. Requires ceramic tools and slow speeds. Destroys cutters. | Jet engine turbines, rocket nozzles. |

7. Engineering Plastics: Not Just for Toys

Lightweight, chemical resistant, and electrically insulating.

| Grade | Common Name | The Material Scientist (Performance) | The Machining Expert (Manufacturability) | Best For |

| POM | Delrin / Acetal | High stiffness, low friction, dimensionally stable. | Rating: 5/5. The “Machinist’s Plastic.” Cuts like brass. No coolant needed. | Gears, bushings, insulators. |

| PEEK | The Super Plastic | High temp resistance (250°C), chemical proof, radiolucent. | Rating: 3.5/5. Stable but expensive ($$). Abrasive to tools due to fiber reinforcement (if GF/CF filled). | Medical implants, semiconductor parts. |

| Nylon | PA6 / PA66 | Tough and impact resistant. Absorbs moisture. | Rating: 3/5. Can melt if cut too fast. Difficult to hold tight tolerances as it expands/contracts with humidity. | Wear pads, rollers, wheels. |

| PC | Polycarbonate | Optically clear, high impact strength. | Rating: 3/5. Prone to cracking (crazing) with dull tools. Polishing required for clarity. | Windows, guards, medical housings. |

Summary of CNC Material: How to Choose? (The Quick Checklist)

- Does it need to be welded? Avoid 303 Stainless and 7075 Aluminum.

- Is it a high-volume turned part? Use 12L14 Steel or 303 Stainless to save 50% on cost.

- Does it need to conduct electricity? Try C145 Tellurium Copper before C101 Pure Copper.

- Is weight a factor? Look at Titanium Gr 5 or Aluminum 7075.

- Is it a cosmetic part? Aluminum 6063 anodizes better than 6061.

Still Unsure your cNC Material? Let Our Engineers Help.

Material selection is a balance of price, performance, and producibility. At CNMP, we don’t just machine parts; we optimize them.

- Need a quick price comparison? Upload your CAD files to our Instant Quote System and switch between materials to see the cost difference in real-time.

- Have a complex requirement? Read more about our CNC Milling Services or Contact Our Engineering Team for a free DFM (Design for Manufacturability) review.

Once you’ve picked your material, don’t forget the finish. Check out our Guide to Surface Finishes.