The Bible of CNC Aluminum Alloy: 20+ Alloys & The Critical “Temper” System (T6, T651, O, H)

By The CNMP Expert Team

In our previous guide, we covered the basics. But professional engineering requires precision. In the world of CNC machining, specifying “Aluminu

m 6061″ is technically incomplete. Did you mean 6061-O? 6061-T6? Or 6061-T651?

The difference between these suffixes is the difference between a part that machines like butter and a part that warps, tears, and fails.

This is the definitive guide to the CNC Aluminum Alloy Series and the Temper System, written for engineers who need to go beyond the basics.

Part 1: The “Secret Code” of CNC Aluminum Alloy Tempers (Don’t Skip This!)

Before we look at the metals, we must understand the suffix. The “State” or “Temper” dictates the hardness and internal stress of the material.

The Materials Scientist Explains:

CNC aluminum alloys fall into two categories: Heat Treatable (2xxx, 6xxx, 7xxx) and Non-Heat Treatable (1xxx, 3xxx, 5xxx).

1. The “O” State (Annealed)

- Definition: The material has been heated and cooled slowly to its softest possible state.

- Machinability: TERRIBLE.

- Why: “O” state aluminum is soft, gummy, and ductile. It does not cut; it tears. It creates massive “built-up edge” (BUE) on tools.

- Use Case: Deep drawing, bending, or forming. Never buy ‘O’ state for CNC milling unless you plan to heat treat it afterwards.

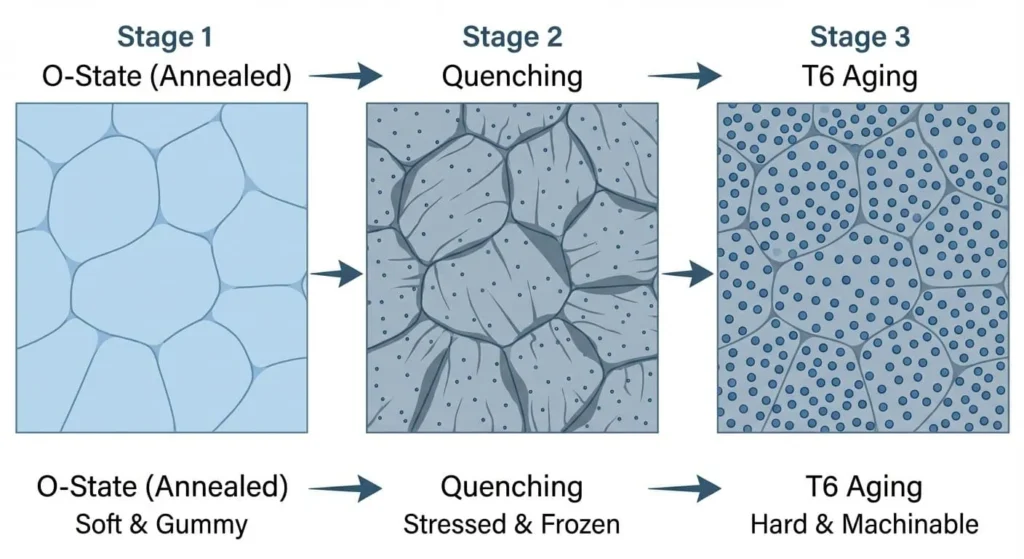

2. The “T” State (Thermally Treated)

Used for 2000, 6000, 7000 series. This is what you want for CNC.

- T3 (Solution Heat Treated + Cold Worked): Common in 2024-T3. High strength, fair machinability.

- T4 (Solution Heat Treated + Naturally Aged): Has not reached peak hardness yet. More formable than T6, but slightly gummier to machine.

- T6 (Solution Heat Treated + Artificially Aged): The industry standard. Maximum precipitation hardening. Strong, stiff, and chips break cleanly.

- T651 (Stress Relieved):CRITICAL FOR MACHINING.

- The Shop Floor Reality: Standard T6 has internal stresses from quenching. When you machine away the “skin,” the part warps. T651 has been mechanically stretched (1-3%) to relieve this stress.

- Advice: Always specify T651 for plates or large flat parts to ensure flatness.

3. The “H” State (Strain Hardened)

Used for 3003, 5052 (Non-heat treatable).

- H32 / H34: Hardened by cold rolling (strain). You cannot heat treat these to make them harder. They are generally difficult (gummy) to machine compared to T-series.

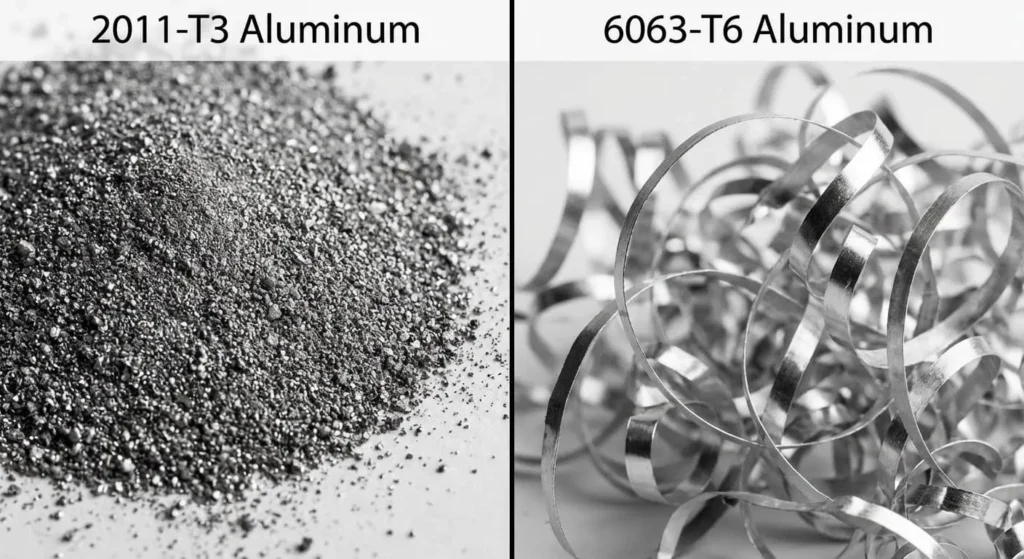

Part 2: The 2000 Series (CNC Aluminum Alloys) – The “Free Machining” Kings

Alloyed with Copper. High Strength, Poor Corrosion Resistance.

| Grade | Temper | Characteristics | CNC Suitability | Application |

| 2011 | T3 | “Free Machining Alloy” (FMA). Contains Lead/Bismuth. Chips turn into tiny dust. The fastest machining cnc CNC Aluminum Alloy in existence. | 10/10. Ideal for Swiss Screw Machines (Lathes). | Complex turned parts, fittings, clock parts. |

| 2024 | T3 / T4 | High fatigue strength. The “Aircraft Skin” alloy. | 8/10. Machines very well (crisp). Needs protective coating (Anodize/Clad) to stop corrosion. | Aerospace structures, high-tension bolts. |

| 2017 | T4 | Older version of 2011/2024. Good machinability and strength. | 7/10. Largely replaced by 2011/2024 but still seen in legacy drawings. | Rivets, general fasteners. |

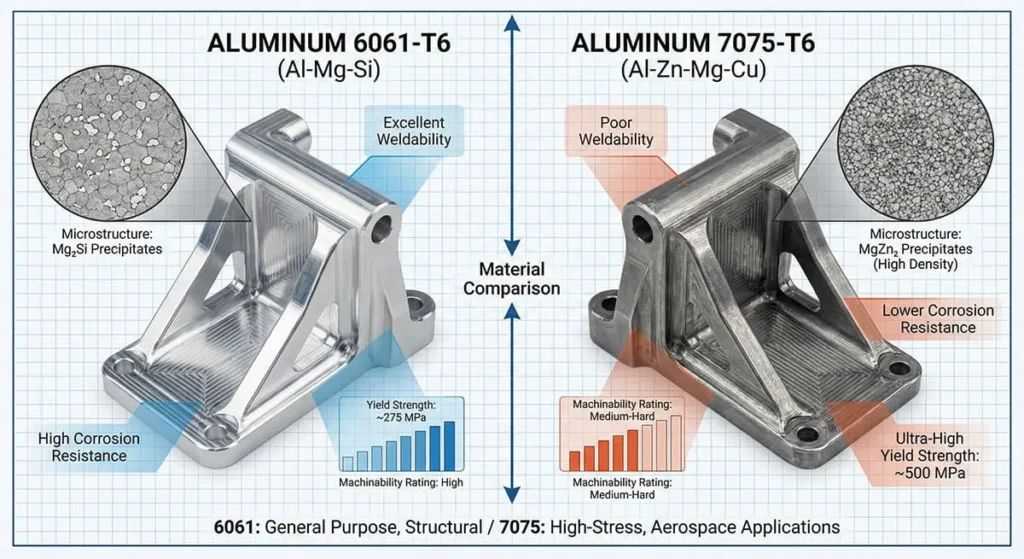

Part 3: The 6000 Series (Mg + Si) – The Structural Standard

The most versatile family. Heat treatable.

| Grade | Temper | Characteristics | CNC Suitability | Application |

| 6061 | T6 / T651 | The Global Standard. Good strength, weldable, corrosion-resistant. | 9/10. The default choice for milling. Always ask for T651 for plates. | General engineering, robotics, frames. |

| 6082 | T6 / T651 | The “European 6061”. Higher Manganese content. Slightly stronger than 6061. Excellent corrosion resistance. | 9/10. Chips break similarly to 6061. Very common in ISO markets. | Structural components, trusses, bridges. |

| 6063 | T5 / T6 | Optimized for extrusions and surface finish. Weaker than 6061. | 6/10. Gummy. Great for anodizing, tricky for tight tolerances. | Heatsinks, window frames, cosmetic housing. |

| 6060 | T6 | Very similar to 6063 but with tighter impurity control. Common in Europe. | 6/10. Optimized for anodizing speed and color consistency. | Decorative trim, lighting fixtures. |

Part 4: The 7000 Series (Zinc) – The Heavy Hitters

Highest strength. Expensive.

| Grade | Temper | Characteristics | CNC Suitability | Application |

| 7075 | T6 / T651 | “Aircraft Grade.” Strength comparable to some steels. Brittle chips. | 9/10. Finishes beautifully due to hardness. Expensive. | Aerospace, gears, shafts, climbing gear. |

| 7050 | T7451 | The “Thick Plate” Upgrade. 7075 has issues with stress corrosion cracking in thick plates (>3 inches). 7050 solves this. | 9/10. More stable than 7075 in heavy sections. Essential for aerospace bulkheads. | Thick aerospace structural parts, fuselage frames. |

| QC-10 | T651 | Mold Aluminum. Developed by Alcoa. High strength and thermal conductivity. 40% faster cycle times for injection molding than steel. | 9/10. Machines specifically for high-polish finishes. | Injection molds, blow molds. |

Part 5: The “Gummy” Series (1xxx, 3xxx, 5xxx) – Proceed with Caution

Non-Heat Treatable. Hardened by “H” (Strain). Great for bending, bad for milling.

| Grade | Temper | Characteristics | CNC Suitability | Application |

| 5052 | H32 | Marine grade. Best salt resistance. Excellent for bending/welding. | 3/10. Very gummy. Leaves large burrs. Not recommended for complex milling. | Sheet metal, fuel tanks, marine cabinets. |

| 5083 | H111 / H116 | Stronger than 5052. The standard for ship hulls. | 4/10. Slightly better than 5052 but still gummy. Use for large, simple marine structures. | Shipbuilding, armored vehicles. |

| 3003 | H14 | Manganese alloy. Very soft. General purpose sheet metal. | 2/10. Extremely gummy. Clogs end mills instantly. Avoid milling. | Spun parts, cooking utensils. |

| 1100 | O / H14 | 99% Pure Aluminum. Highest electrical/thermal conductivity. Softest alloy. | 1/10. Like machining chewing gum. Only use if conductivity is the #1 priority. | Chemical equipment, electrical busbars. |

Part 6: Expert Checklist – Specifying the Right CNC Aluminum Alloy

Don’t just write “Alum” on your drawing. Use this logic:

- Is it a high-speed turned part (Lathe)?

- Yes ➡ 2011-T3. It will save you 40% in cycle time.

- Is it a large flat plate that must be perfectly flat?

- Yes ➡ MIC6 (Cast) or 6061-T651 (Stress Relieved). Do not use standard T6.

- Does it need to be welded?

- Yes ➡ 6061-T6 or 5052. (Do not weld 7075 or 2024, they will crack).

- Is it a thick structural block for Aerospace?

- Yes ➡ 7050-T7451 (Better stress/corrosion profile than 7075).

- Is it purely for looks (Anodizing)?

- Yes ➡ 6063 or 6060.

A Note from the Shop Floor:

“We often receive drawings asking for 1100-O for a complex milled housing. We have to call the client and explain: ‘We can make this, but the surface finish will look torn, and de-burring will cost more than the machining.’ Switching to 6061-T6 usually solves the problem instantly.”

Unlock the Full Potential of CNC Aluminum Alloy

At CNMP, we stock over 15 grades of CNC Aluminum Alloy in various tempers. We understand the nuances of the T-state.

- Not sure if you need T6 or T651?

- Need to switch from European 6082 to American 6061?

Upload your drawings for a free engineering review and quote. We’ll help you pick the grade that balances performance with machinability.