The Ultimate Guide to CNC Carbon Steel: Structural, Alloy, & Tool Grades Explained

By The CNMP Expert Team

When engineers specify “Steel” on a drawing, they are opening a Pandora’s box.

Carbon steel is the backbone of the manufacturing industry, but it is not a single material. It is a vast family. Choosing the wrong type of carbon steel can lead to parts that rust instantly, shafts that snap under torque, or machining costs that spiral out of control because the material is too “gummy.”

To make the right decision, you must understand the 5 distinct categories of carbon steel used in CNC machining.

In this guide, we analyze Carbon Structural Steel, Quality Carbon Steel, Free-Cutting Steel, Alloy Structural Steel, and Carbon Tool Steel. We break them down by their performance (The Science) and their manufacturability (The Shop Floor).

1. Carbon Structural Steel: The Economy Choice (1018 / A36)

The “Construction” Grade. Low cost, high ductility.

We start with the most basic form of steel. In the industry, this is often referred to as “Mild Steel.”

AISI 1018 (Carbon Structural Steel)

- The Science: This steel contains very low carbon (<0.18%). It is essentially pure iron with a ferrite matrix. It is soft and ductile.

- The Machinist: “Rating: 3/5. Gummy & Tearing.””Don’t be fooled. Just because this steel is soft doesn’t mean it’s easy to finish. It tears rather than cuts. It creates long, stringy chips that clog the machine. Achieving a mirror finish on 1018 is difficult because the material drags.”

- Best For: Welding fixtures, mounting brackets, base plates.

- Warning: Not suitable for precision shafts as it warps due to internal stress.

2. Quality Carbon Structural Steel: The Precision Standard (1045)

The “Machine” Grade. Balanced strength and finish.

When you need reliable mechanical properties, you upgrade from “Structural” to “Quality Carbon Structural Steel.”

AISI 1045 (Quality Carbon Steel)

- The Science: The carbon content is increased to ~0.45%. This introduces “Pearlite” into the microstructure, making this steel significantly harder and stronger than 1018. It is heat-treatable.

- The Machinist: “Rating: 4/5. The Machinist’s Favorite.””This is the gold standard for steel components. Because it is harder, the chip snaps cleanly instead of tearing. We can achieve a beautiful shiny surface finish on turned parts using 1045 steel.”

- Best For: Axles, hydraulic rams, bolts, gears.

3. Free-Cutting Carbon Steel: The Speed Demon (12L14)

The “Volume” Grade. Designed for mass production.

If you are making 10,000 screws, you need Free-Cutting Carbon Steel (also known as Free-Machining).

AISI 12L14 (Leaded Carbon Steel)

- The Science: This steel has Lead (Pb) and Sulfur added. The lead acts as an internal lubricant, while the sulfur creates inclusions that act as microscopic chip breakers.

- The Machinist: “Rating: 5+/5. Dust-like Chips.””This is the fastest machining metal on earth. The steel chips turn to dust instantly. We can run our CNC machines at max RPM. It reduces cycle time by 50% compared to standard steel.”

- The Trade-off: Low strength and cannot be welded (toxic fumes).

- Best For: Standoffs, bushings, inserts.

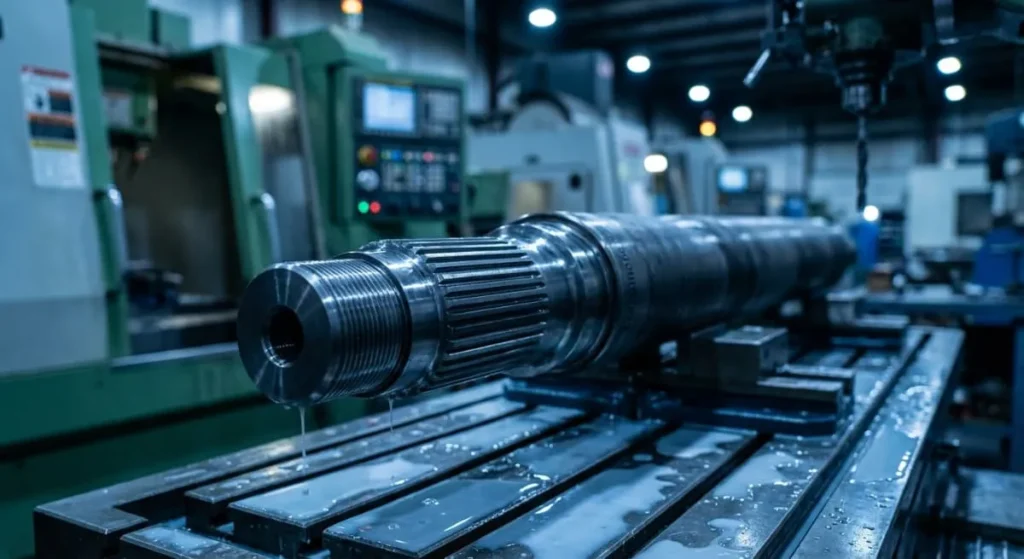

4. Alloy Structural Steel: The Heavy Duty Option (4140)

The “Toughness” Grade. Added Chromium and Molybdenum.

While technically an alloy, this category is often grouped with carbon steel in purchasing. It is the go-to for high-stress applications.

AISI 4140 (Chromoly Steel)

- The Science: A steel base alloyed with Chromium and Molybdenum. This gives it incredible fatigue strength and impact resistance.

- The Machinist: “Rating: 3.5/5. Tough but Consistent.””We usually machine this steel alloy in the ‘Pre-Hardened’ (PH) state. It is tough, but it doesn’t gum up like 1018. It holds tight tolerances because the material is stable.”

- Best For: Drive shafts, connecting rods, high-stress bolts.

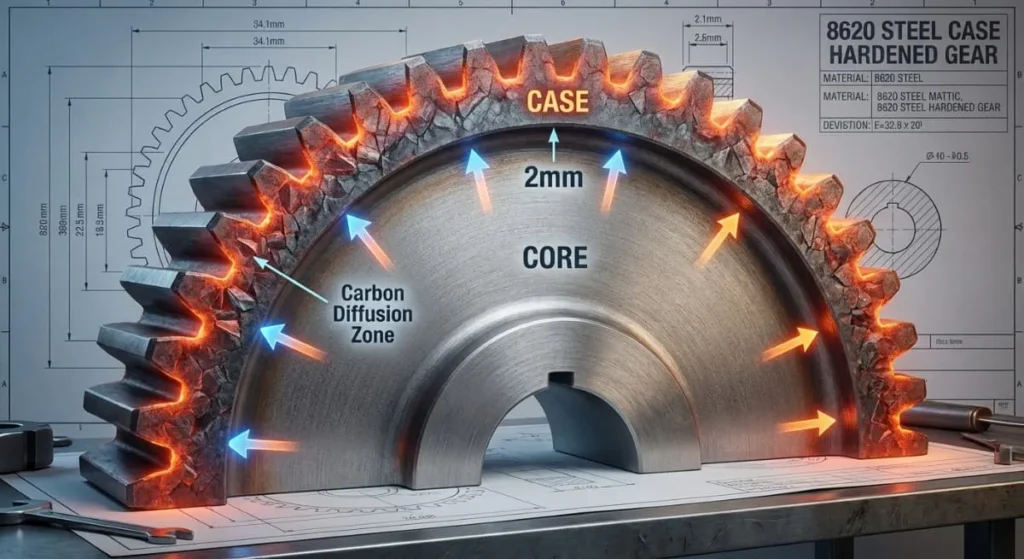

AISI 8620 (Carburizing Steel)

- The Science: Designed for “Case Hardening.” The outer skin becomes glass-hard while the steel core remains tough and ductile.

- Best For: Gears and camshafts.

5. Carbon Tool Steel: Extreme Hardness (O1 / D2)

The “Cutting” Grade. Used to make other tools.

The final category is Carbon Tool Steel. These grades have high carbon content (~0.9% to 1.5%) to hold a sharp edge.

AISI O1 (Oil Hardening Carbon Steel)

- The Machinist: “Machines easily when annealed (soft). After machining, we quench it in oil to make this steel extremely hard (HRC 60+).”

- Best For: Jigs, fixtures, stamping punches.

AISI D2 (High Carbon / High Chrome)

- The Machinist: “Rating: 1/5. Abrasive.””This is a difficult steel to machine. It contains massive carbides that eat tool tips. It is used for dies that need to survive millions of cycles.”

Visualizing Carbon Steel Properties

To understand why one carbon steel cuts better than another, look at the microstructure.

Visual 1: Chip Formation (1018 vs 1045)

Prompt: Macro photography comparison of steel machining chips. Left side labeled “1018 STRUCTURAL CARBON STEEL”: Chips are long, continuous, stringy, and blue (heat tinted). Right side labeled “1045 QUALITY CARBON STEEL”: Chips are short, broken “C” shapes, shiny silver. Industrial lighting.

Alt Text: Comparison of machining chips between 1018 and 1045.

Visual 2: The Free-Cutting Microstructure

Prompt: Scientific microscope diagram of 12L14 steel. Grey background matrix. Yellow dots labeled “Lead/Sulfur Inclusions”. A CNC tool bit hits a yellow dot, causing the chip to fracture. Text overlay: “Chip Breaker Mechanism”.

Alt Text: Microstructure of free-cutting carbon steel showing inclusions that improve machinability.

Summary Matrix: Choosing the Right Carbon Steel

| Grade | Category | Machinability | Strength | Weldability | Cost |

| 1018 | Carbon Structural Steel | 3/5 (Gummy) | Med | Excellent | $ |

| 1045 | Quality Carbon Steel | 4/5 (Clean) | High | Good | $$ |

| 12L14 | Free-Cutting Carbon Steel | 5+/5 (Fast) | Low | NO | $$ |

| 4140 | Alloy Structural Steel | 3.5/5 (Tough) | V. High | Fair | $$$ |

| O1 | Carbon Tool Steel | 4/5 (Soft) | N/A | High (Hard) | $$$ |

Expert Tip: Don’t Forget the Finish

Carbon steel will rust. Always specify a surface finish:

- Zinc Plating: Best for Structural carbon steel.

- Black Oxide: Best for Tool carbon steel.

- Nickel Plating: Best for cosmetic carbon steel parts.

Ready to start?

Contact CNMP to get a quote on your precision carbon steel parts today.