What Is CNC Machining? A Complete and Practical Guide

Introduction

In today’s fast-paced manufacturing landscape, CNC machining—short for Computer Numerical Control machining—has become the foundation of precision engineering.

From aerospace components and automotive systems to custom medical devices, CNC machining powers nearly every modern industry.

But what exactly is CNC machining?

How does it work, and why has it become the preferred choice for both prototyping and large-scale production?

This guide will take you through everything you need to know—from how CNC machining works to the materials, machine types, advantages, and real-world applications—so that you can make informed decisions whether you’re an engineer, buyer, or project manager.

H2: Understanding the Core Principle of CNC Machining

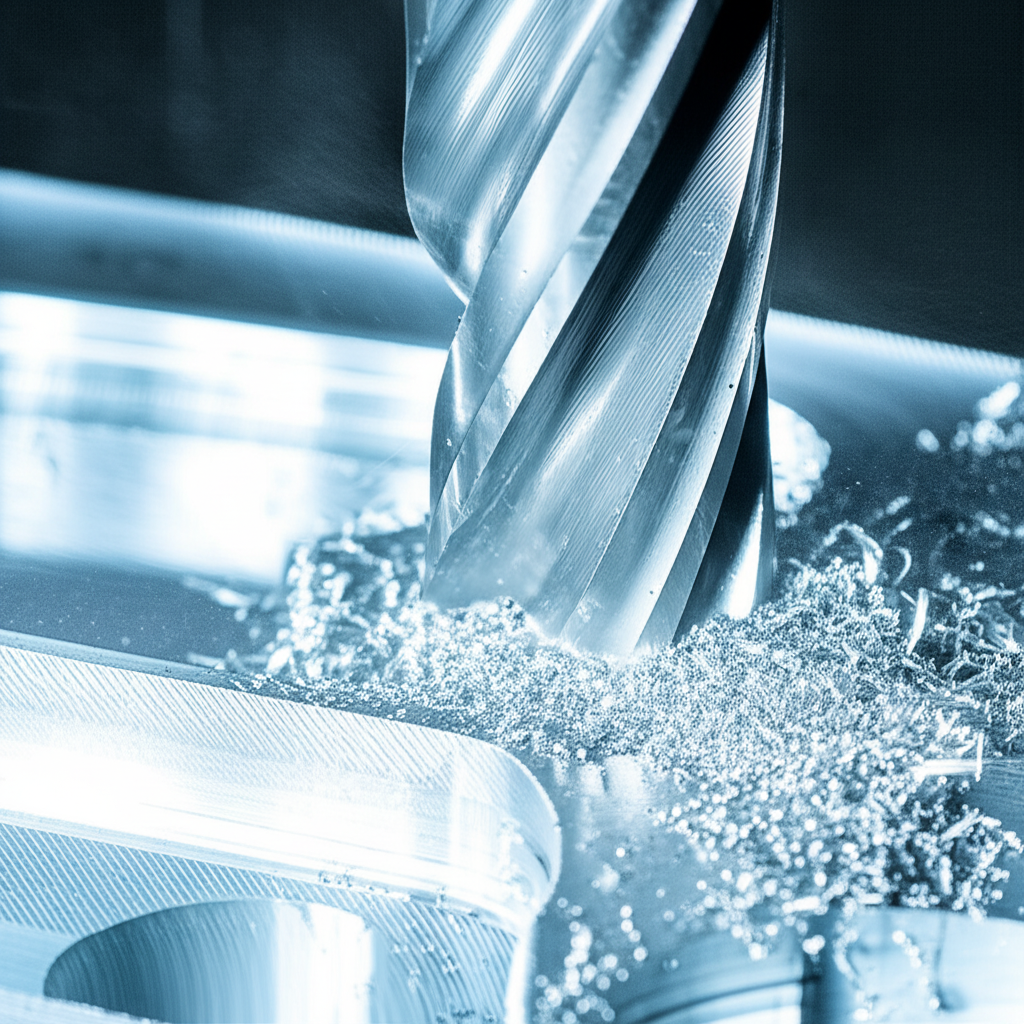

CNC machining is a subtractive manufacturing process—it starts with a solid block of material (metal or plastic) and removes layers until the final geometry is achieved.

Unlike manual machining, every motion of the cutting tool, spindle, and feed rate is controlled by computer instructions (G-code) generated from a 3D CAD model.

This digital workflow ensures:

- High precision — tolerances as tight as ±0.005 mm

- Repeatability — identical parts produced consistently

- Automation — minimal operator intervention

- Efficiency — reduced lead time and waste

The beauty of CNC machining lies in its versatility: from one-off prototypes to high-volume production, it delivers accuracy that manual processes simply cannot match.

H2: The CNC Machining Process Explained Step-by-Step

To understand CNC machining deeply, let’s break down the typical workflow:

H3: 1. CAD Design

Every CNC project begins with a 3D CAD model, representing the final shape of the part.

This design defines every curve, angle, and tolerance — serving as the “blueprint” for the machine to follow.

H3: 2. CAM Programming

Next, the CAD file is converted into CAM software (Computer-Aided Manufacturing), which translates geometry into G-code—a language that CNC machines understand.

Here, engineers decide:

- Tool paths

- Cutting speed

- Feed rate

- Depth of cut

A well-optimized tool path directly affects machining time, surface quality, and tool life.

H3: 3. Machine Setup

Operators then prepare the CNC machine by:

- Mounting the right cutting tools

- Securing the workpiece on a fixture

- Calibrating zero points for X, Y, and Z axes

Proper setup ensures stability and accuracy throughout the machining process.

H3: 4. Machining Execution

Once programmed, the CNC machine automatically executes all movements.

Depending on the design, the process may include:

- Milling (for complex surfaces)

- Turning (for cylindrical parts)

- Drilling or Tapping (for holes and threads)

- Cutting or Engraving (for patterns or markings)

H3: 5. Finishing and Inspection

After machining, parts undergo:

- Deburring or polishing for a smooth finish

- Dimensional inspection using CMM (Coordinate Measuring Machine)

- Surface treatments like anodizing, plating, or coating

This ensures every part meets required specifications before shipment.

H2: Different Types of CNC Machines

Each CNC machine is designed for specific shapes and tolerances:

H3: CNC Milling Machines

These use rotating cutting tools to remove material from a stationary workpiece.

They’re ideal for complex geometries—pockets, holes, channels, and curved surfaces.

Modern 5-axis milling enables cutting from multiple directions in a single setup, saving time and improving precision.

H3: CNC Turning (Lathes)

In CNC turning, the workpiece rotates while a fixed cutting tool shapes its exterior.

It’s perfect for producing shafts, rings, and cylindrical components like bushings and pistons.

H3: CNC Drilling

Specialized machines perform drilling, tapping, and countersinking with extreme accuracy.

They’re often integrated into multi-axis centers for efficiency.

H3: EDM (Electrical Discharge Machining)

Used for hard metals or intricate details where traditional tools can’t reach.

It uses electrical sparks to erode material with micrometer precision.

H2: Common Materials Used in CNC Machining

CNC machining supports a diverse range of materials, each chosen based on mechanical, thermal, or aesthetic properties:

- Aluminum (6061, 7075): Lightweight, corrosion-resistant, and excellent machinability.

- Stainless Steel (304, 316): High strength and rust resistance for medical and food-grade parts.

- Brass: Great for fittings, valves, and aesthetic components.

- Titanium: High strength-to-weight ratio, ideal for aerospace and medical implants.

- Copper: Exceptional electrical and thermal conductivity.

- Engineering Plastics (POM, Nylon, PEEK): Non-conductive, lightweight, and cost-effective alternatives to metal.

📎 Internal Link Suggestion: Learn more: How to Choose the Right Material for CNC Machining →

H2: Advantages of CNC Machining

CNC machining stands out for its blend of precision, flexibility, and reliability.

Here are its top benefits:

- Accuracy and Repeatability: Consistent performance even across thousands of parts.

- Speed: Automated cutting paths significantly reduce cycle times.

- Material Flexibility: Works with almost any machinable metal or plastic.

- Surface Quality: Achieves smooth finishes without heavy polishing.

- Scalability: Suitable for both single prototypes and full production runs.

- Cost Efficiency: Reduces labor time and minimizes human error.

H2: Key Applications Across Industries

CNC machining plays a central role in modern manufacturing sectors:

- Automotive: Precision gears, engine housings, and transmission parts.

- Aerospace: Lightweight titanium and aluminum components with strict tolerance control.

- Medical: Custom surgical tools and biocompatible implants.

- Energy & Hydraulics: Pump housings, valve blocks, and sealing surfaces.

- Consumer Hardware: Stainless steel fittings, knobs, and decorative elements.

📎 Internal Link Suggestion: See how CNMP serves these industries →

H2: CNC Machining vs. 3D Printing — Which to Choose?

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Process Type | Subtractive | Additive |

| Material Range | Metals & Plastics | Mostly Plastics |

| Tolerance | ±0.005 mm | ±0.1 mm |

| Surface Finish | Excellent | Often requires post-processing |

| Production Scale | Prototype → Mass | Prototype & Small Batch |

💡 Insight:

CNC machining is best for functional, load-bearing parts requiring high strength and precision.

3D printing is excellent for rapid prototyping or design validation.

H2: Limitations and Considerations

Despite its versatility, CNC machining isn’t ideal for every situation:

- Higher waste material compared to additive manufacturing.

- Initial setup cost can be higher for small runs.

- Complex internal geometries may be impossible with subtractive methods.

However, the unmatched precision and surface integrity often justify these trade-offs—especially in high-performance industries.

Conclusion

CNC machining represents the perfect blend of digital precision and mechanical craftsmanship.

It enables manufacturers to produce reliable, repeatable, and complex parts from a variety of materials—all within tight tolerances and short lead times.

For engineers and procurement specialists, understanding CNC machining means understanding how modern manufacturing truly works.

If you’re designing a new part, developing a prototype, or seeking a reliable production partner—

👉 Contact CNMP today to discuss your CNC machining needs or request a free quotation.