Introduction

When it comes to manufacturing custom components for harsh environments—whether for aerospace, medical devices, or marine applications—stainless steel remains the gold standard. However, sourcing reliable stainless steel CNC machining services can often feel like navigating a minefield. You need a partner who understands that stainless steel is not just “harder steel”—it is a complex alloy prone to work-hardening, poor thermal conductivity, and tool wear if not handled correctly.

If you have struggled with suppliers who deliver parts with poor surface finishes, out-of-tolerance dimensions, or communication delays, you are not alone. This guide is designed to bridge the gap between your engineering drawings and the final product. We will explore the technical nuances of machining stainless steel, how to select the right alloy for your project, and how to secure high-quality parts at competitive rates.

Whether you are a procurement manager looking for wholesale stainless steel CNC machining services or an engineer seeking a single prototype, understanding the process is the key to success.

Why Stainless Steel? Understanding the Material

Before diving into the machining process, it is critical to understand the material itself. Stainless steel is an alloy of iron with a minimum of 10.5% chromium. This chromium creates a passive layer of oxide on the surface that prevents corrosion.

However, from a machinist’s perspective, stainless steel presents specific challenges:

- High Tensile Strength: It requires rigid machine setups.

- Work Hardening: If the cutting tool dwells in one spot too long, the material hardens instantly, making further cutting difficult.

- Gumminess: Certain grades can be “gummy,” leading to long, stringy chips that can entangle tooling.

Popular Grades We Machine

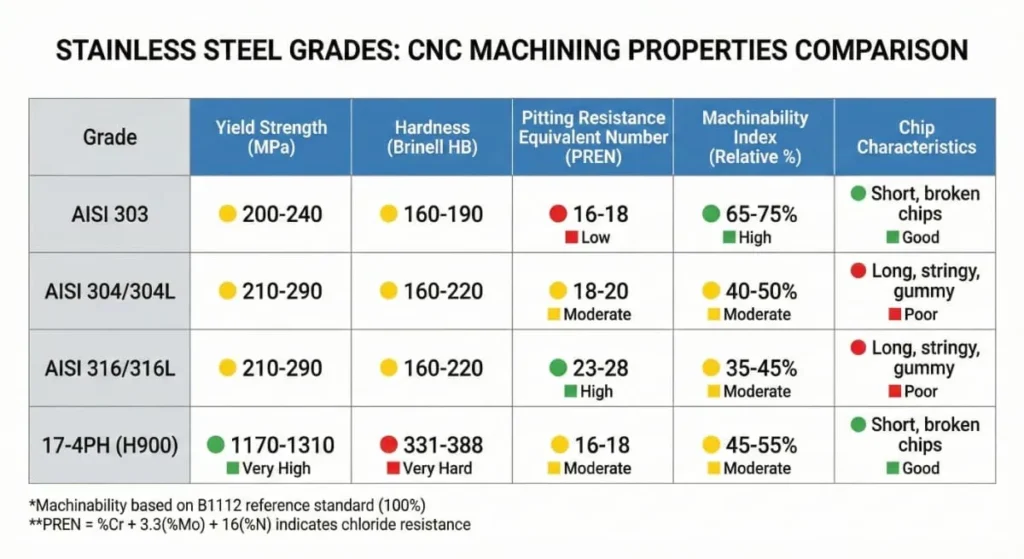

Selecting the right grade affects both the performance of your part and the cost of the stainless steel CNC machining service.

- Austenitic (300 Series):

- 303: The “free-machining” grade. Sulfur is added to make it easier to cut. Ideally used for fittings and shafts, but has lower corrosion resistance than 304.

- 304/304L: The most common grade. Excellent corrosion resistance and formability. It is the industry standard for general enclosures and brackets.

- 316/316L: Contains Molybdenum, making it highly resistant to chlorides and acids. This is the go-to for marine and medical applications.

- Martensitic & Precipitation Hardening:

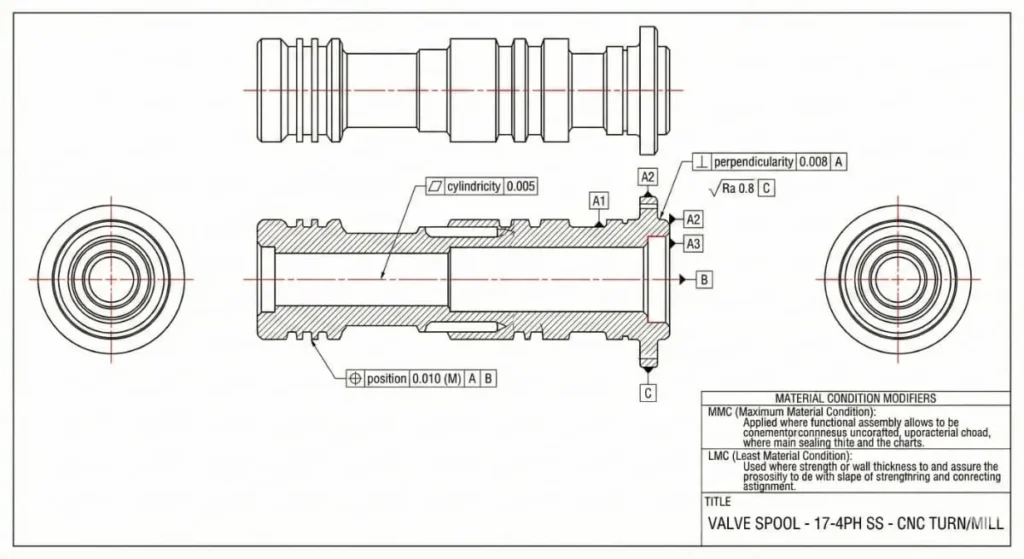

- 17-4PH: Offers a blend of high strength and good corrosion resistance. It can be heat-treated to achieve varying levels of hardness.

- 400 Series (e.g., 416, 420): Magnetic and heat-treatable, often used for gears and wear-resistant parts.

Expert Tip: If your part does not require welding or extreme corrosion resistance, specifying Grade 303 can significantly lower the cost of machining due to faster cycle times and reduced tool wear.

Our Core Capabilities: Comprehensive Stainless Steel CNC Machining Services

We don’t just cut metal; we engineer solutions. Our factory is equipped to handle complex geometries and tight tolerances that standard job shops often decline.

CNC Milling Services

Our milling department utilizes 3-axis and 4-axis machines to create complex prismatic shapes. For stainless steel, rigidity is key. We use heavy-duty vertical machining centers (VMCs) capable of high torque at lower RPMs to shear through stainless steel without chattering.

- Applications: Housings, brackets, engine components, and mounting plates.

- Capacity: We can handle block sizes up to 1000mm with tolerances as tight as +/- 0.01mm.

CNC Turning Services

For cylindrical parts, our CNC turning centers offer precision and speed. We utilize live tooling, which allows us to mill slots or drill holes into a part while it is still on the lathe. This “Done-in-One” approach reduces handling time and improves accuracy.

- Applications: Shafts, pins, bushings, and custom fasteners.

- Efficiency: Automated bar feeders allow us to offer wholesale stainless steel CNC machining services for high-volume orders.

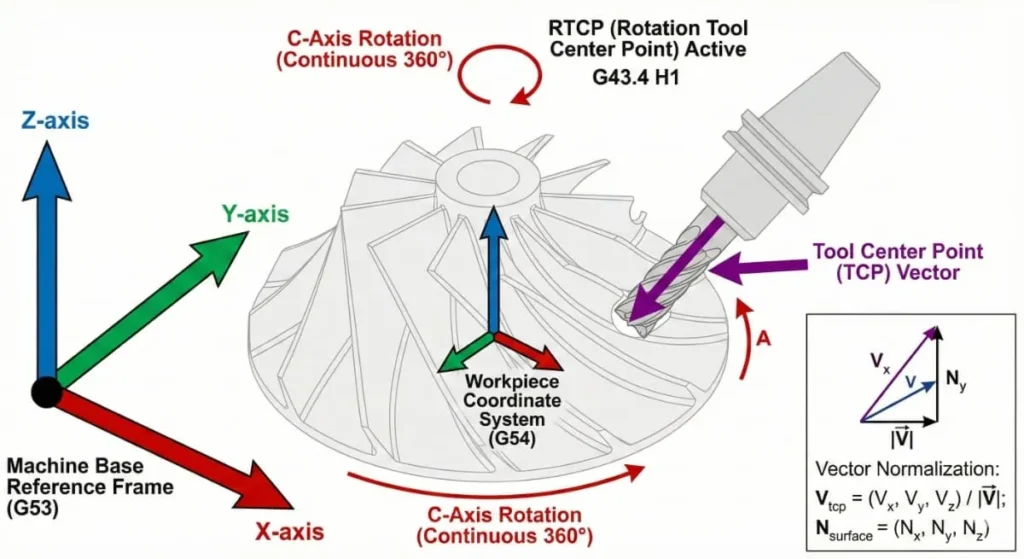

5-Axis CNC Machining

When your design involves complex curves, undercuts, or angled holes, 5-axis machining is the solution. By moving the cutting tool along five different axes simultaneously, we can machine a part from five sides in a single setup.

- Benefit: Reduces fixture errors and dramatically shortens lead times for complex parts like impellers or medical implants.

Technical Challenges and How We Overcome Them

This section demonstrates why we are the experts. Machining stainless steel requires a scientific approach to cut parameters. Here is how we ensure quality where others fail.

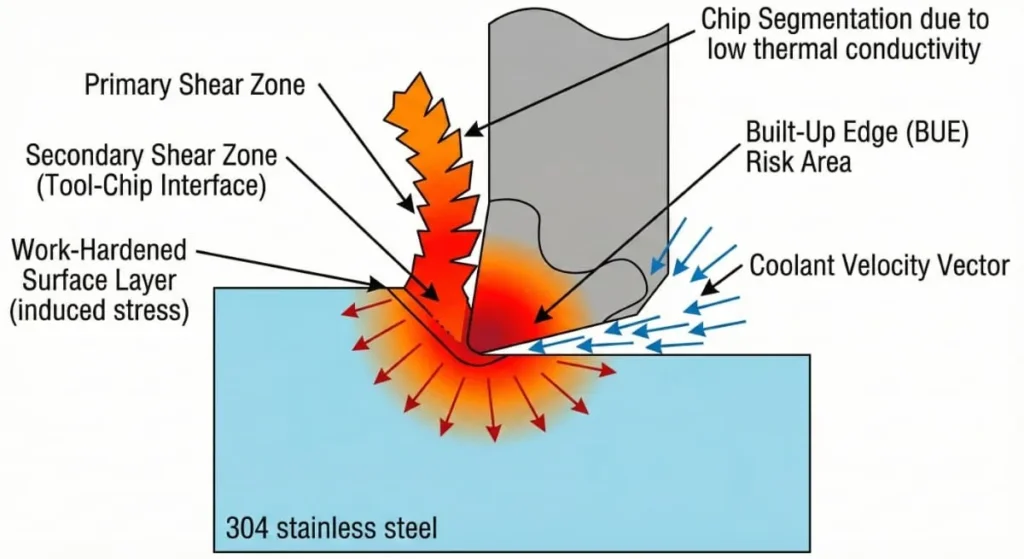

Combating Heat Build-Up

Stainless steel is a poor conductor of heat. Unlike aluminum, where the heat exits with the chip, stainless keeps the heat in the cutting tool and the workpiece.

- Our Solution: We use high-pressure coolant systems (up to 1000 PSI) to blast chips away and keep the cutting zone cool. This prevents thermal expansion, ensuring your parts stay within tolerance.

Preventing Work Hardening

As mentioned, stainless steel hardens if you “baby” the cut.

- Our Solution: Our programmers use aggressive feed rates and constant cutter engagement strategies (trochoidal milling). We use premium carbide tooling with specific coatings (like TiAlN) designed to withstand the heat and abrasion of stainless steel.

Tool Chatter and Vibration

Vibration leads to poor surface finishes (chatter marks).

- Our Solution: We maintain our machines meticulously to ensure spindle runout is near zero. We also utilize short, rigid tool holders and specialized vibration-dampening boring bars for deep internal turning.

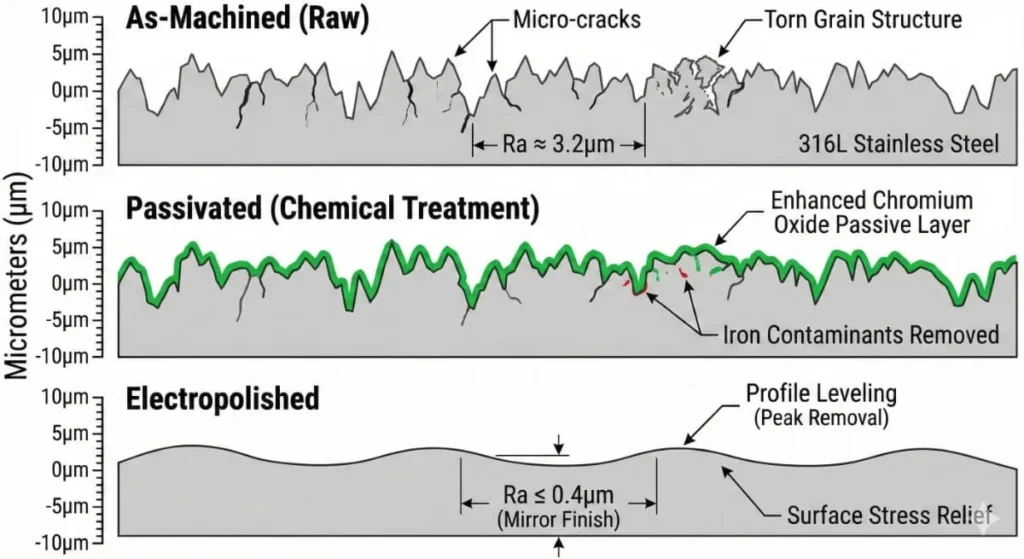

Surface Finishing for Stainless Steel Parts

A raw machined part is rarely the final product. To enhance durability and aesthetics, we offer a full suite of finishing options.

- Passivation: A chemical bath that removes surface iron contaminants, enhancing the natural corrosion resistance of the steel. This is mandatory for most medical and aerospace parts.

- Bead Blasting: Sprays fine glass beads at the part to create a uniform, matte texture. It hides minor machining marks and reduces glare.

- Electropolishing: The reverse of plating. It removes a microscopic layer of material, leaving a bright, mirror-like finish that is ultra-clean and resistant to bacteria growth.

- PVD Coating: For decorative or wear-resistant applications, creating a hard, colored surface (gold, black, iridescent).

How to Choose the Best Partner for Your Project

Finding the best cnc machining service for brass and stainless steel requires looking beyond just the hourly rate. You need to evaluate the supplier’s ecosystem.

Inspection and Quality Control (Metrology)

Does the supplier have a CMM (Coordinate Measuring Machine)? Stainless steel parts often have tight tolerances. We utilize:

- CMM Inspection: For 3D geometric validation.

- Optical Comparators: For checking profiles and threads.

- Material Certification: We provide material test reports (MTRs) with every shipment to prove the chemical composition of the steel (e.g., verifying it is genuine 316L).

Communication and DFM

The best cnc machining service for brass and stainless steel acts as a consultant, not just a printer. Our engineers review your CAD files for Design for Manufacturability (DFM). We might suggest adding a radius to an internal corner to allow for a stronger tool, effectively reducing machining time and cost without compromising functionality.

Pricing Strategy: Wholesale and Cost Optimization

Price is always a factor. You might be searching for cheap price stainless steel cnc machining services, but in manufacturing, “cheap” can be dangerous if it sacrifices material quality. Instead, we focus on “Cost-Efficiency.”

How We Lower Costs Without Lowering Quality

- Smart Programming: We optimize tool paths to reduce air-cutting time.

- Wholesale Production: We offer tiered pricing. Setup costs (programming, fixturing) are amortized over the quantity. Ordering 100 parts is significantly cheaper per unit than ordering 1.

- Standard Tooling: We design processes around standard cutting tools to avoid custom tool charges.

If you are looking for wholesale stainless steel cnc machining services, we can set up blanket orders. You order 5,000 parts for the year; we manufacture them in batches and ship them as you need them, locking in the lower price and saving you warehousing space.

Comparing Stainless Steel to Other Metals

While we are discussing the best cnc machining service for brass and stainless steel, it is worth noting the cost difference. Brass machines much faster than stainless steel (almost as fast as aluminum). If corrosion resistance is not the primary concern, or if the part is purely decorative, switching to brass can reduce machining costs by 30-40%. However, for strength and durability, stainless remains the champion.

Case Study: Custom Valve Components for the Oil & Gas Industry

The Challenge: A client in the UK required a 316L stainless steel valve body. The part featured complex internal channels and a strict surface finish requirement of Ra 0.4 to prevent leakage under high pressure.

The Solution:

- We utilized our stainless steel cnc machining service with 5-axis capability to reach the internal angles.

- We implemented a custom boring bar to achieve the smooth internal finish.

- We performed 100% pressure testing before shipment.

The Result: The client received parts that passed inspection on the first try, reducing their assembly line rejection rate from 15% (with previous supplier) to 0%.

Frequently Asked Questions (FAQ)

Here are answers to common questions we receive regarding our stainless steel cnc machining service.

Q1: What is the typical lead time for stainless steel parts?

A: For prototypes (1-10 parts), our standard lead time is 5-7 business days. For wholesale stainless steel cnc machining services (100+ parts), typical lead time is 15-20 days, depending on the complexity and finishing requirements.

Q2: Can you hold tight tolerances on stainless steel?

A: Yes. We routinely hold tolerances of +/- 0.01mm (+/- 0.0004″). For critical features, we can grind parts to achieve even tighter precision.

Q3: Do you handle both brass and stainless steel?

A: Absolutely. We are often cited as the best cnc machining service for brass and stainless steel because we keep these material streams separate to prevent cross-contamination, which is vital for medical and electronic parts.

Q4: Is “cheap price stainless steel cnc machining services” a red flag?

A: It depends. If the price is below the cost of raw material, yes. However, we offer competitive pricing by utilizing automation and low-overhead manufacturing in China, allowing us to pass significant savings to you without compromising ISO standards.

If you want to more know more or get quote,you can contact us.

Conclusion

Sourcing custom parts shouldn’t be a gamble. Whether you are developing a new prototype or looking for wholesale stainless steel cnc machining services to scale your production, the right partner makes all the difference.

We combine state-of-the-art 5-axis technology, deep metallurgical knowledge, and strict ISO quality control to deliver parts that meet your exact specifications. Don’t settle for “good enough” when you can have precision, durability, and aesthetic perfection.

Ready to start your project?

Stop worrying about tolerance issues and material failures. Upload your CAD files today for a free DFM review and a competitive quote within 24 hours. Let us show you why we are the trusted choice for stainless steel cnc machining services globally.

References & Further Reading:

- ISO 9001:2015 Quality Management Principles

- ASTM A240 / A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip