The Industrial Finish Guide: Powder Coating vs Painting for CNC Parts

By The CNMP Expert Team

You have machined a beautiful aluminum enclosure. Now you need it to be black, durable, and branded.

You have two main choices: Powder Coating or Wet Painting.

To the untrained eye, they might look similar. But to an engineer, they are worlds apart.

- Powder Coating is the heavy-duty “armor” of the manufacturing world.

- Wet Painting is the precise “cosmetic suit.”

Choosing the wrong one leads to expensive failures. We have seen powder-coated parts that are so thick they won’t fit together, and painted parts that chip the moment they are installed.

In this guide, we break down the powder coating vs painting debate, analyzing the durability, cost, and the hidden engineering risks like the “Faraday Cage Effect.”

What is the Difference? (The Science)

One is melted plastic; the other is solvent-based.

Powder Coating: The “Dry” Process

- How it works: We spray a dry, electrostatically charged plastic powder onto a grounded metal part. The powder sticks like a magnet. The part is then baked in an oven at 200°C (400°F). The powder melts, flows, and cures into a solid, continuous skin.

- Key Feature: No solvents (VOCs). It is purely physical melting.

Wet Painting: The “Liquid” Process

- How it works: Pigment is suspended in a solvent. It is sprayed onto the surface. As the solvent evaporates (air drying or low-heat baking), the pigment remains.

- Key Feature: High precision. The layer is thin and smooth.

Round 1: Durability & Toughness

The Hammer Test.

If your product is going to live outdoors, get kicked, or handle heavy machinery, Powder Coating wins, hands down.

- Powder Performance: It is flexible. If you hit it with a hammer, it dents with the metal. It resists scratching, fading, and chipping.

- Paint Performance: It is brittle. Impact causes it to shatter or flake off.

Expert Insight:

“For CNC machined chassis, roll bars, and industrial brackets, we always recommend powder. It is essentially a layer of melted plastic armor.”

Round 2: Aesthetics & Smoothness

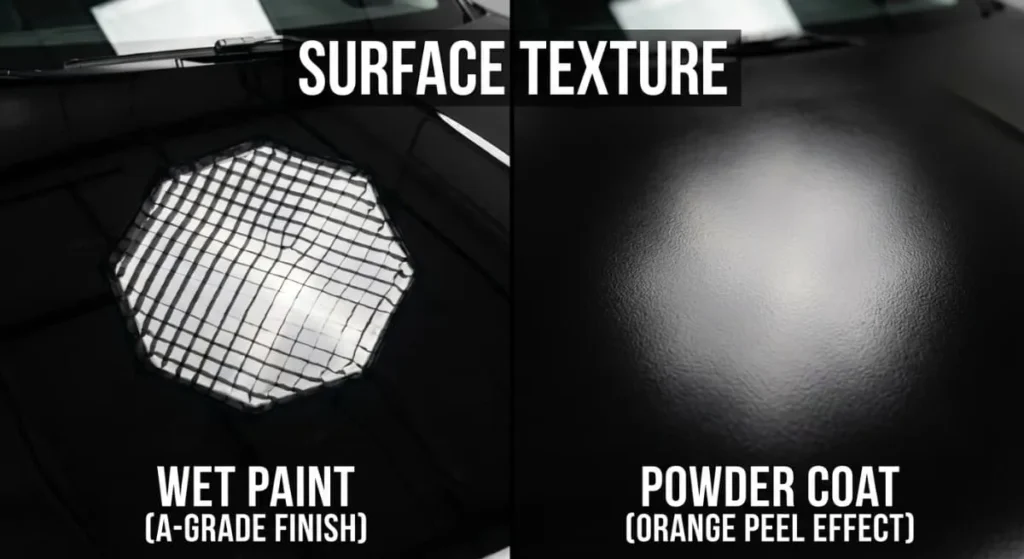

The “Orange Peel” Problem.

This is where Wet Painting shines.

- The “Orange Peel” Effect: Because powder has to melt and flow, it rarely cures perfectly flat. It usually has a bumpy texture, similar to the skin of an orange.

- The “Class A” Finish: Wet paint can be applied perfectly smooth (think of a car body). It creates a high-gloss, mirror-like finish that powder cannot replicate.

- Color Matching:

- Paint: We can mix any custom Pantone color in-house.

- Powder: We must buy pre-mixed powder in 20kg boxes. If you need a custom color for just 5 parts, it is prohibitively expensive.

Round 3: Engineering Risks (The “Gotchas”)

Why engineers hate Powder Coating.

In the powder coating vs painting decision, you must consider Geometry and Tolerance.

1. The Tolerance Trap (Thickness)

- Paint: Very thin (10-20 microns). Negligible impact on fit.

- Powder:Very Thick (60-100 microns).

- The Risk: If you powder coat a precision bore or a threaded hole, the bolt will not fit.

- The Fix: We must use high-temperature silicone plugs to Mask every critical surface. This adds labor cost.

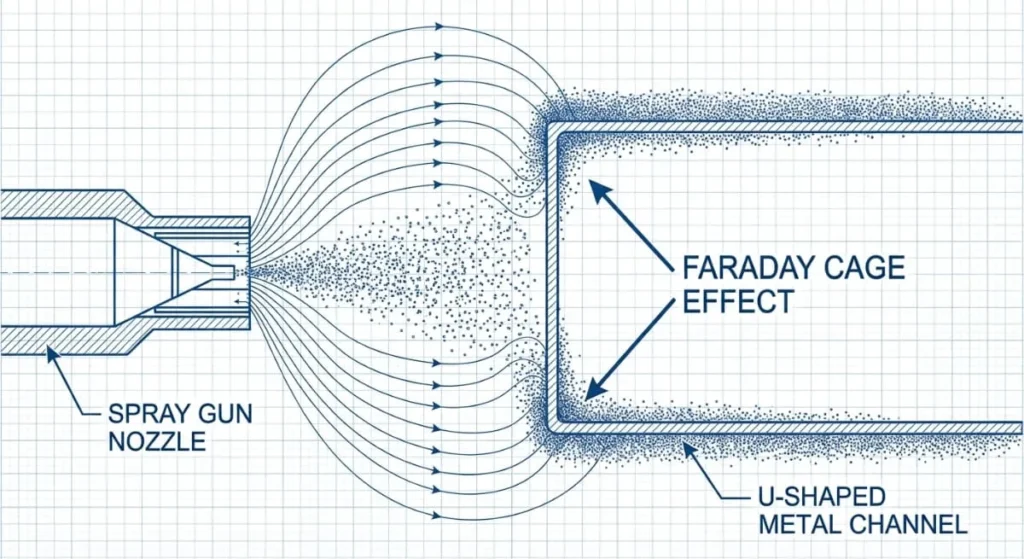

2. The Faraday Cage Effect

This is a physics phenomenon unique to electrostatic spraying.

- The Problem: If your CNC part has a deep, sharp inside corner (like a heat sink fin or a box interior), the electricity repels the powder from the corner.

- The Result: The flat surfaces get too much powder, while the corners get zero coverage (bare metal).

- Design Tip: Add large radii to internal corners to allow the powder to penetrate.

Round 4: Material Limitations

Heat kills plastics.

- Powder Coating Requirement: The part must survive a 200°C oven.

- Compatible: Aluminum, Steel, Stainless Steel, Brass.

- Impossible: Plastics (they melt), Carbon Fiber (resin degrades), soldered assemblies.

- Wet Painting Requirement: Can be air-dried.

- Compatible: Everything. You can paint ABS plastic, wood, or complex electronic assemblies.

Comparison Matrix: Powder Coating vs Painting

| Feature | Powder Coating | Wet Painting |

| Durability | Extreme (Impact/Scratch resistant) | Moderate (Prone to chipping) |

| Cost (High Vol) | Low (Powder can be recycled) | Medium (Wasteful overspray) |

| Cost (Low Vol) | High (Setup is heavy) | Low (Easy setup) |

| Thickness | Thick (60-100µm) | Thin (15-25µm) |

| Texture | “Orange Peel” / Textured | Class A Smooth / High Gloss |

| Masking | Critical (Thick build-up) | Less Critical |

| Environment | Eco-Friendly (No VOCs) | High VOCs (Solvents) |

Summary: Which Finish Should You Choose?

- Choose Powder Coating If:

- You are making industrial equipment, outdoor brackets, or durable consumer goods.

- You have a high quantity (50+ parts) to offset setup costs.

- You want an eco-friendly process.

- Choose Wet Painting If:

- You need a specific custom color for a prototype (1-10 parts).

- You need a “Piano Black” high-gloss cosmetic finish.

- The part is made of plastic or composite.

- You have extremely tight tolerances that cannot be masked.

Still undecided?

Don’t let the finish ruin the fit. Contact CNMP for a consultation. We can advise if your geometry is susceptible to the Faraday Cage effect.Appendix: