The Ultimate Guide to Plastic Machining: 10+ Grades, Process & Molding Alternatives

By The CNMP Expert Team

When designing a plastic component, engineers often face a dilemma: Mold it or Machine it?

While injection molding rules high-volume production, plastic machining is the unsung hero of precision engineering. It is the only way to get tight tolerances, zero tooling costs, and complex geometries without a $10,000 mold investment.

However, plastic machining is deceptively difficult. It requires a completely different understanding of thermodynamics compared to metal.

In this comprehensive guide, we analyze over 10 types of machinable plastics—from cheap prototypes to high-performance aerospace polymers—helping you choose the right material for your project.

The “Big 3” Challenges in Plastic Machining

Why it’s harder than metal.

Before choosing a material, you must understand the risks.

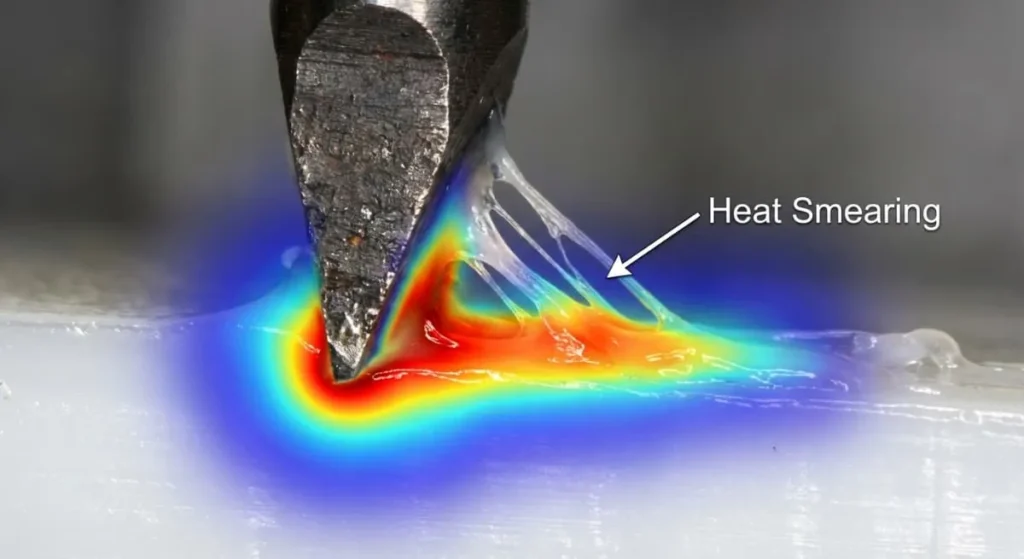

1. Heat Build-Up (The Melting Hazard)

- The Science: Plastics are thermal insulators. unlike Aluminum which dissipates heat, plastics trap heat.

- The Machinist: “If we run a dull tool too fast during plastic machining, the material doesn’t cut—it smears. It melts and re-welds itself behind the cutter.”

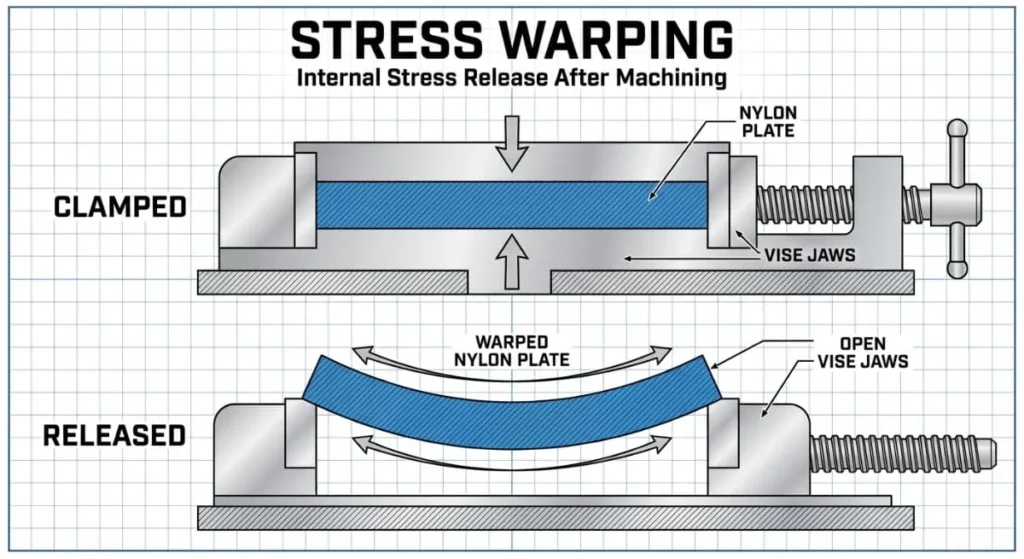

2. Internal Stress (The Warping Hazard)

- The Science: Extruded plastics contain massive internal stress. Removing the outer skin releases this stress, causing the part to bow.

- The Fix: We often “Anneal” (stress relieve) the material before the final finishing pass.

3. Clamping Deformation

- The Reality: You cannot crush plastic in a vise like Carbon Steel. It compresses, then expands when released, ruining the tolerance.

Category 1: General Purpose & Prototyping Plastics

Low cost, easy to machine, moderate strength.

ABS (Acrylonitrile Butadiene Styrene)

- The “Lego” Plastic.

- Machinability: 5/5 (Excellent). It cuts cleanly and easily.

- Best For: Impact-resistant housings, prototypes for injection molded parts. It can be easily glued/bonded.

- Expert Note: ABS is the cheapest entry point for plastic machining verification models.

PVC (Polyvinyl Chloride)

- The “Pipe” Plastic.

- Machinability: 3.5/5. Cheap and chemically resistant.

- Warning: It releases Chlorine gas if burned or cut too hot (corrosive to machines).

- Best For: Chemical tanks, manifolds, plumbing fittings.

Acrylic (PMMA)

- The “Glass” Substitute.

- Machinability: 2.5/5 (Brittle). It creates clear chips but cracks easily if the tool grabs.

- Best For: Light pipes, screens, display cases. Easier to polish than PC.

Category 2: Engineering Plastics

The workhorses of industry. Balanced performance.

POM / Acetal (Delrin)

- The Machinist’s Favorite.

- Machinability: 5/5. High stiffness, low friction, short chips. It holds the tightest tolerances of any plastic (±0.02mm).

- Best For: Precision gears, bushings, sliding guides.

Nylon (PA6 / PA66)

- The “Tough” One.

- Machinability: 3.5/5. Creates long, stringy chips (“bird nests”).

- The Trap: Nylon is hygroscopic (absorbs water). A part machined to spec today might expand tomorrow in humid air.

- Best For: Wear pads, rollers, high-impact parts.

UHMW-PE (Ultra-High Molecular Weight Polyethylene)

- The “Slippery” One.

- Machinability: 2/5 (Tricky). It is so slippery and waxy that it’s hard to clamp. It doesn’t cut crisply; it tears.

- Best For: Conveyor guide rails, food processing chutes (FDA safe).

PET / PET-P (Ertalyte)

- The “Stable” Nylon Alternative.

- Performance: Similar strength to Nylon but absorbs ZERO moisture. Ideal for precise wet environments.

- Best For: Food machinery parts, valves.

Category 3: High-Performance & Clear Plastics

Extreme heat, clarity, or chemical resistance.

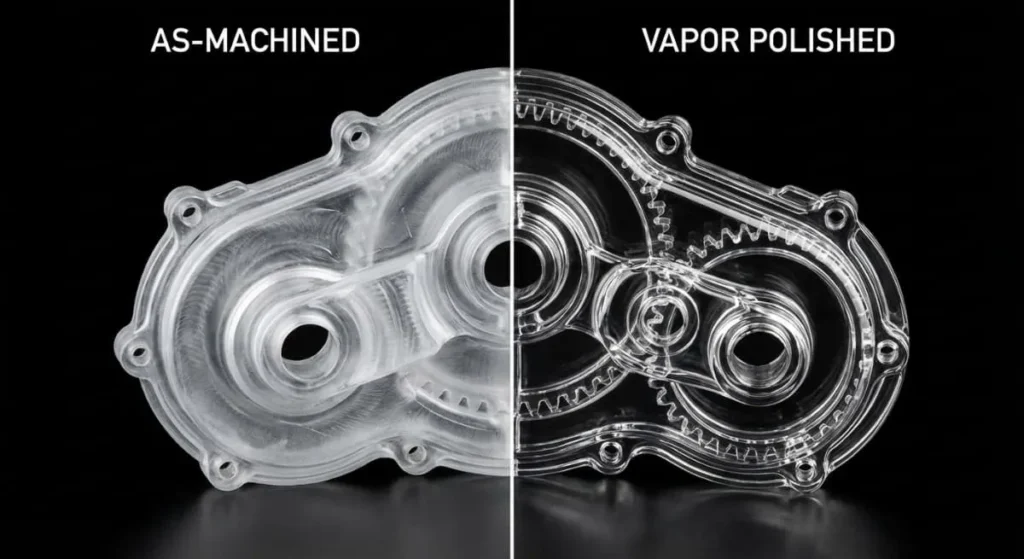

Polycarbonate (PC)

- The “Bulletproof” Clear.

- Machinability: 3/5. Tougher than Acrylic but harder to polish.

- Finish: Requires Vapor Polishing to restore clarity after plastic machining.

PEEK (Polyetheretherketone)

- The “Metal Replacement”.

- Performance: Withstands 260°C (500°F). Strong, stiff, and chemical resistant.

- Machinability: 4/5. Cuts beautifully (like hard wood) but is extremely expensive ($$$$).

- Comparison: If you need heat resistance but PEEK is too expensive, consider Stainless Steel 316.

- Best For: Medical implants, semiconductor parts, aerospace insulators.

Ultem (PEI)

- The “Amber” PEEK.

- Performance: Slightly lower temp rating than PEEK, but cheaper and translucent amber color. Excellent dielectric strength.

- Best For: Aircraft electrical connectors.

PTFE (Teflon)

- The “Softest”.

- Machinability: 2/5. Cuts like cold butter. Very hard to hold dimensions because it deforms under any pressure.

- Best For: Seals, gaskets, chemical liners.

Category 4: Composites (The Tool Killers)

Fiber-reinforced plastics.

G10 / FR4 (Garolite)

- The Science: Epoxy resin reinforced with glass cloth.

- The Hazard: It is not “cutting” plastic; it is “grinding” glass. It destroys standard tools in minutes. We must use Diamond-coated tools.

- Safety: Produces dangerous glass dust (requires respirators).

- Best For: PCB insulation boards, high-voltage spacers.

Selection Matrix: Choosing the Right Grade

| Material | Cost | Heat Limit | Tolerance | Best Feature |

| ABS | $ | 70°C | Good | Cheap, Glueable |

| POM | $$ | 90°C | Best | Stable, Low Friction |

| Nylon | $$ | 100°C | Fair | Tough, Wear Resist |

| UHMW | $$ | 80°C | Poor | Slick, Abrasion Resist |

| PC | $$ | 120°C | Good | Transparent, Impact |

| PEEK | $$$$$ | 260°C | Excellent | Extreme Performance |

| G10 | $$$ | 140°C | Good | Electrical Insulation |

Expert Advice: Tolerance Expectations

Plastic is not Metal. Tolerances of ±0.01mm are extremely risky.

- For POM/PEEK, aim for ±0.05mm.

- For Nylon/UHMW, aim for ±0.10mm.

Ready to start?

Contact CNMP to get a DFM review for your plastic machining project.