How to Choose the Right Material for CNC Machining

Choosing the right material for CNC machining is a critical engineering decision that affects part performance, manufacturability, and total cost. The right material reduces iterations, shortens lead time, and prevents failures in service. This guide gives a practical, engineering-first approach to selecting materials—so you can make data-driven decisions, not guesses.

Why material selection matters for precision parts (machining materials)

Materials determine a wide range of downstream outcomes: strength, weight, corrosion resistance, thermal behavior, surface finish and how the material cuts. A mismatch between design intent and material choice often shows up as excessive tool wear, surface defects, or parts that fail in field testing.

Use material selection to optimize the entire manufacturing chain: design → machining → finishing → inspection → service life.

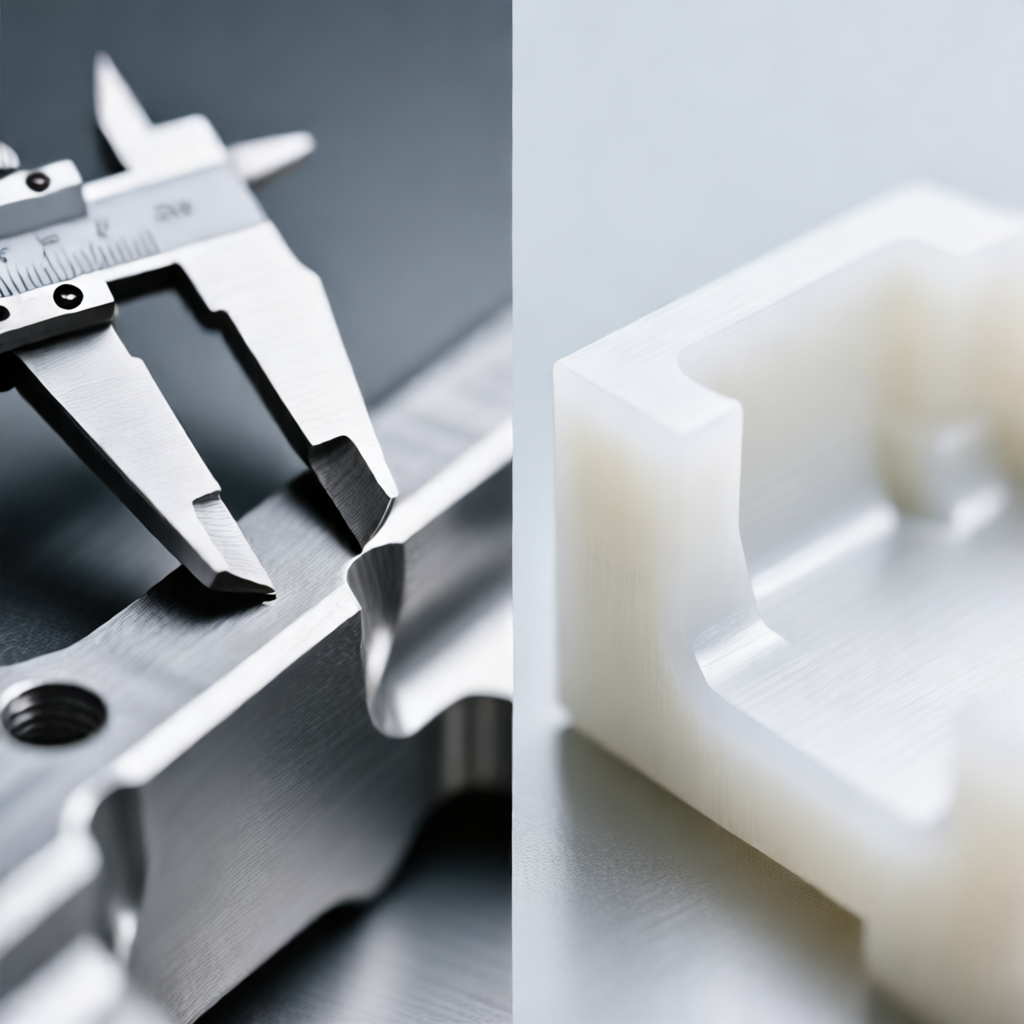

Metals vs plastics — practical trade-offs (metals vs plastics)

When metals are the right choice

Metals provide stiffness, durability and higher temperature capability — essential for load-bearing, wear-prone, or high-temperature parts. Typical scenarios:

- Structural components, shafts and housings that require fatigue resistance.

- Parts exposed to chemicals or moisture where corrosion resistance is needed (e.g., 316 stainless).

- High-precision mating surfaces that must hold tight tolerances under load.

When plastics are preferable

Engineering plastics reduce weight and cost, offer electrical insulation, and often simplify assembly. Typical scenarios:

- Low-load or non-structural components where weight matters (e.g., ABS enclosures).

- Sliding or low-friction parts where low wear plastics like POM (Delrin) excel.

- High-performance environments requiring chemical or heat resistance (PEEK).

Key material properties to evaluate

Narrow down options by comparing objective material properties against the part’s functional requirements. Start with this checklist:

- Tensile strength & yield: for load-bearing parts.

- Hardness: affects wear resistance and tooling strategy.

- Modulus of elasticity: stiffness and deflection under load.

- Thermal expansion & conductivity: critical for tight-tolerance assemblies and heat-exposed parts.

- Corrosion & chemical resistance: choose stainless, titanium or suitable coatings when needed.

Machinability & CNC tolerances (machinability & CNC tolerances)

Machinability drives cycle time, tooling costs and achievable surface finish. Select materials that match the tolerances you need and the tools you have.

Practical guidance:

- Easy-to-machine: 6061 aluminum, free-cutting brass — lower cost, faster cycles.

- Moderate difficulty: 304/316 stainless — need sharper tools and controlled feeds.

- Hard to cut: titanium, Inconel — longer cycles, specialized tooling and coolant strategy.

For precision tolerances (e.g., ±0.01 mm or better), pick materials with low thermal expansion and high dimensional stability, and plan for proper fixturing and CMM verification.

Surface finish, post-processing & functional coatings (surface finish)

Think about final surface requirements early: plating, anodizing, passivation, or polished finishes each have material preferences. Surface finishing affects corrosion resistance, wear, and aesthetics.

- Aluminum + anodizing → durable colored finish and improved corrosion resistance.

- Stainless steel + electropolish → superior corrosion resistance and smooth finish for medical parts.

- Brass → excellent for visible parts with high polish requirements.

Cost, availability and supply chain considerations

Raw material cost and lead time can dominate part cost for large volumes. Consider regional supply, certification needs (e.g., mill certificates), and minimum order quantities.

- For prototypes, favor materials that are readily available to shorten lead time.

- For production, lock in supply channels and certificate requirements early (ASTM/ISO grades).

- Factor scrap, rework and tooling life into total part cost not just raw material price.

Design for Manufacturability (DFM) checklist for materials

Before finalizing the material, run this DFM checklist with your manufacturer:

- Can required tolerances be held in one setup or need multiple fixtures?

- Does the material require special tooling or coolant to avoid work hardening?

- Are there thin walls or deep cavities that increase risk of chatter or distortion?

- Is the chosen surface finish achievable without expensive secondary operations?

Validating the choice: prototyping & testing

Material selection is best validated by testing. Prototype with the intended material or a close substitute, then test for fit, function and environmental performance.

- Run functional tests under expected loads, temperatures and fluids.

- Measure dimensional stability after machining and finishing.

- Use CMM reports and surface roughness tests to confirm specs.

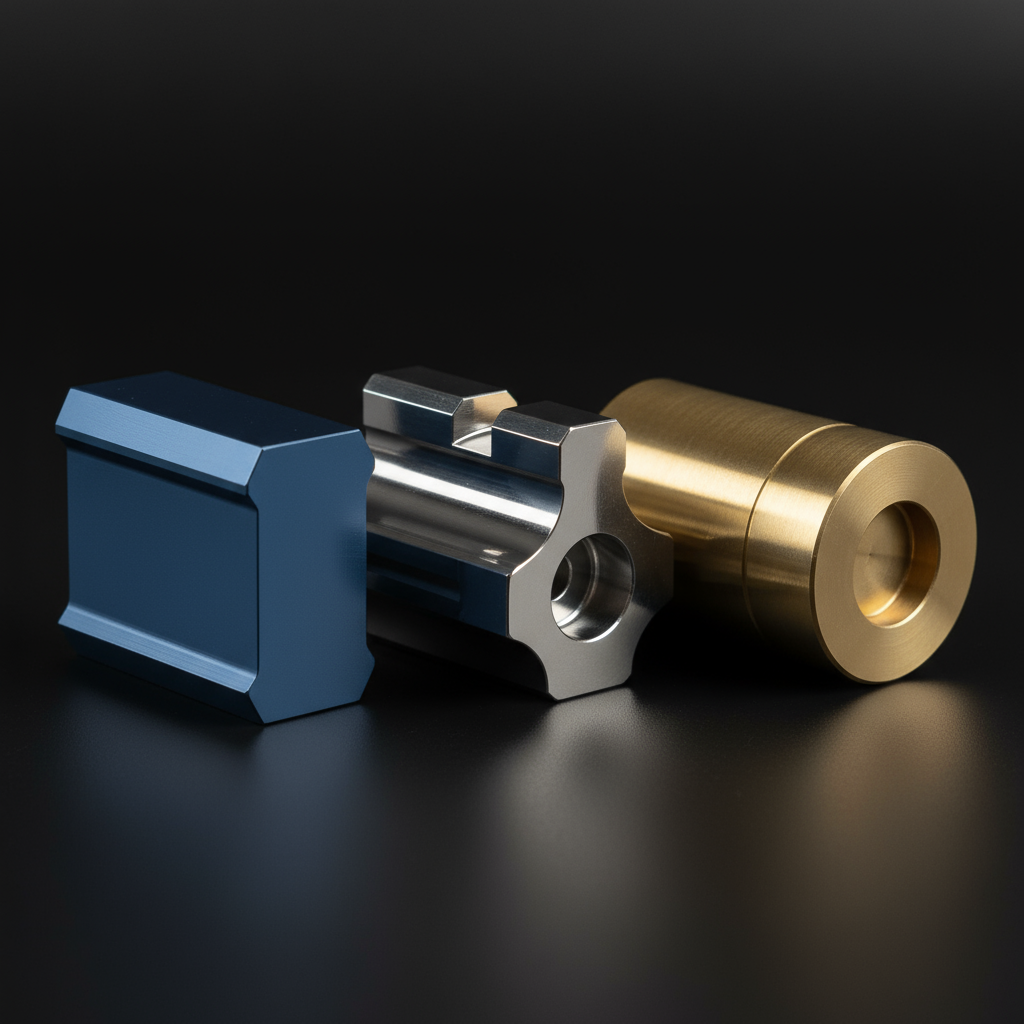

Quick reference: common material recommendations

The following are typical starting points — always confirm with supplier and testing:

- General structural parts: 6061-T6 aluminum or 304 stainless steel.

- High-strength, lightweight: Titanium alloys (costly, for critical aerospace/medical use).

- Hydraulic fittings: Brass or stainless steel with corrosion protection.

- Rotating or sliding parts: POM (Delrin) or bronze depending on load and lubrication.

- High-temp service: PEEK or heat-resistant alloys.

Conclusion — align function, cost and manufacturability (main keyword appears in conclusion)

How to choose the right material for CNC machining comes down to a disciplined trade-off: functional requirements, manufacturability, and total cost. Start by defining loads and environment, compare material properties, validate with prototyping, and confirm process capability with your machining partner.

CNMP’s engineering team works with clients to evaluate materials, perform DFM checks, and run prototype validations so parts meet performance and cost targets. Contact our engineers to discuss materials, request sample machining, or get a detailed quotation.

aaa