Introduction

CNC turned parts are everywhere—from shafts and bushings to threaded connectors—but one bad tolerance, burr, or out-of-round condition can stop an entire assembly line.

If you’re buying from overseas suppliers, you may have already felt the common pain points:

- Parts match the drawing “most of the time,” but lot-to-lot consistency is weak

- Threads don’t gauge, or mating parts seize in assembly

- Surface finish is rougher than expected (or scratched in transit)

- Quoting is slow, questions are unclear, and engineering changes get missed

This guide shows you how to specify, quote, and verify CNC turned parts like a seasoned engineer or buyer—covering tolerances, GD&T, materials, surface finishing, quality control, and a practical RFQ checklist you can copy.

What Are CNC Turned Parts (and Why Buyers Choose Them)

CNC turned parts are components produced on a CNC lathe (or turning center) where the workpiece rotates and a cutting tool removes material to achieve precise diameters, faces, grooves, bores, and threads.

Where CNC turned parts fit best

Turning is typically the most efficient process when your geometry is mainly:

- Cylindrical or round (OD/ID features)

- Coaxial (critical concentricity/runout)

- Threaded (internal/external)

- Produced from bar stock in medium to high quantities

Common applications include:

- Hydraulic/pneumatic fittings

- Motor shafts, spacers, pins, and bushings

- Sensor housings and connectors

- Medical instrument components

- Aerospace sleeves, standoffs, and fastener-like specials

A major advantage is repeatability: once tooling and offsets are dialed in, CNC turned parts can be produced with stable dimensions across batches—assuming the manufacturer has strong process control.

CNC Turning vs. CNC Milling vs. 5-Axis: Which Should You Use?

Many buyers lose time (and money) by choosing the wrong process for the geometry—or by forcing a “turning-only” quote for a part that needs milling features.

Quick comparison (buyer-focused)

| Feature / Need | Turning (Lathe) | Milling (3/4-axis) | 5-Axis Machining |

|---|---|---|---|

| Best geometry | Round / coaxial | Prismatic / flat faces | Complex, multi-face, sculpted |

| Cost efficiency | Excellent for diameters, threads | Excellent for pockets, slots | Best when setups must be minimized |

| Typical setup count | Low (bar-fed can be very low) | Medium | Low for complex parts |

| Key risks | Burrs, chatter on slender parts | Tool access, multiple setups | Programming complexity |

If your component is mostly round but needs flats, cross holes, or milled slots, you may still be buying CNC turned parts—just made on a turning center with live tooling (or finished in a secondary milling operation). We regularly combine CNC turning service + CNC milling services + 5-axis CNC machining service to deliver complete parts from one supplier—reducing handoffs and tolerance stack-up.

Typical Operations Used to Make CNC Turned Parts

Understanding the operations helps you write clearer drawings and avoid avoidable DFM back-and-forth.

Common turning operations:

- Facing (create a flat datum face)

- OD/ID turning

- Boring and reaming

- Grooving and undercutting

- Parting/cutoff

- Drilling, tapping

- Threading (single-point, tapping, thread milling in some cases)

- Knurling (functional grip surfaces)

- Chamfering and edge breaks

Live-tooling turning centers can also add:

- Cross-drilled holes

- Milled flats (D-shafts), hex features

- Keyways and slots

- Engraving/marking

The best suppliers treat CNC turned parts as a controlled process—not “just lathe work.” That difference shows up in assembly performance.

Best Materials for CNC Turned Parts (Metals & Plastics)

Material choice impacts machinability, surface finish, tool wear, and tolerance stability. For overseas procurement, it also impacts traceability—make sure the material callout is unambiguous.

Metals commonly used

- Aluminum (e.g., 6061, 7075): light, corrosion resistant, great machinability

- Stainless steel (303, 304, 316, 17-4PH): corrosion resistance; 303 machines easier, 316 is tougher

- Carbon/alloy steel (1018, 1045, 4140): strength and cost balance; may need plating/black oxide for corrosion

- Brass (C360): excellent machinability, great for fittings

- Titanium (Grade 2/5): high strength-to-weight, harder to machine, higher cost

- Nickel alloys (Inconel, Hastelloy): extreme environments; specialized tooling/process needed

Plastics commonly used

- POM/Delrin: stable, easy machining, good for bushings and insulators

- Nylon (PA): tough but may absorb moisture (dimensional change risk)

- PTFE: chemical resistance; soft—tolerance control is trickier

- PEEK: high-performance; expensive but excellent for demanding use cases

Buyer tip: Always specify a recognized standard where possible (ASTM/EN/ISO grade). For regulated industries, ask for EN 10204 3.1 material certificates to support traceability of CNC turned parts.

Specifying CNC Precision Turned Parts: Tolerances, GD&T, and Surface Finish

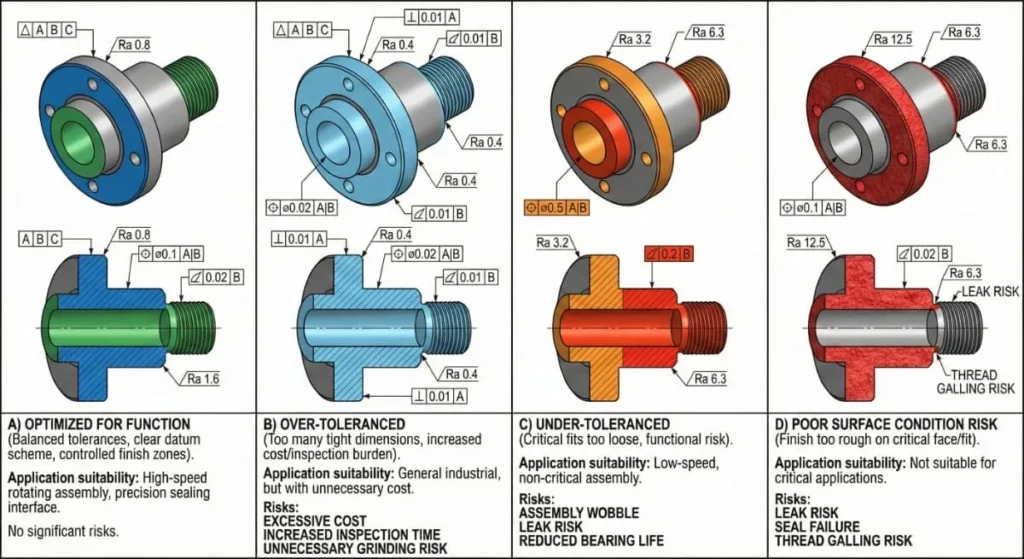

When you need cnc precision turned parts, “tight everywhere” is not a strategy—it’s a cost driver and a risk multiplier. The goal is to apply tight controls only where function requires.

1) What tolerances are realistic?

Capability depends on geometry, material, toolpath strategy, and inspection method. As a practical baseline for many production-grade CNC turned parts:

- General turning: ±0.05 mm (±0.002″)

- Precision turning: ±0.01 mm (±0.0004″) commonly achievable on critical diameters

- High-precision features: ±0.005 mm (±0.0002″) may be achievable with stable process control, but should be reviewed case-by-case

If your drawing uses general tolerances, align to a standard such as ISO 2768 (common in Europe) rather than leaving tolerance assumptions open.

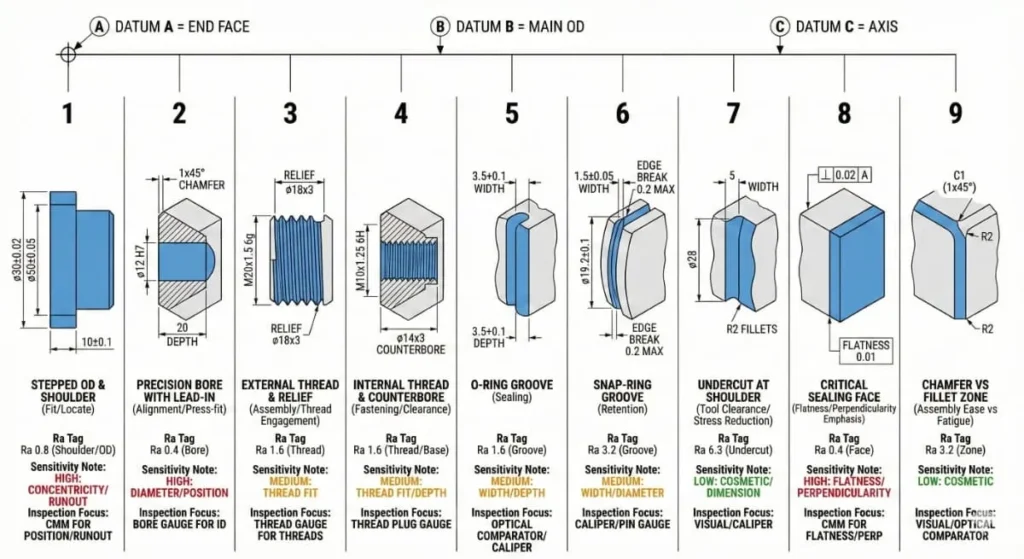

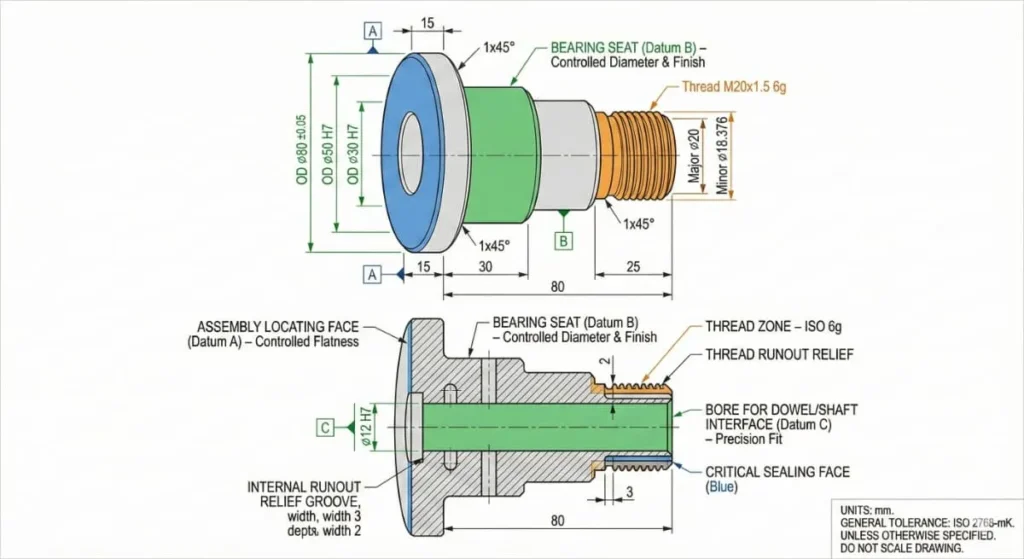

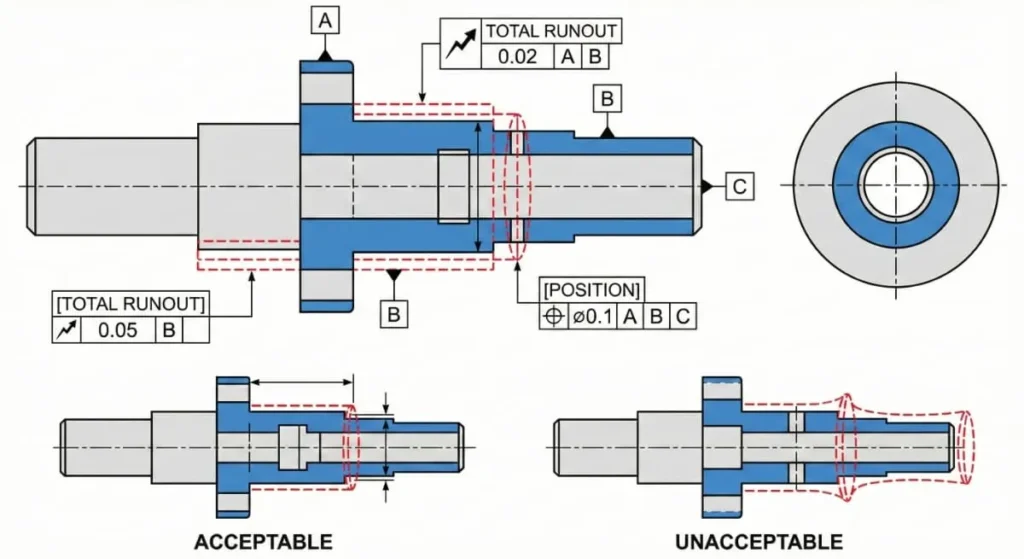

2) Use GD&T to protect function (and reduce cost)

For coaxial parts, GD&T often communicates intent better than multiple tight ± tolerances.

Common controls for CNC turned parts include:

- Total runout / circular runout to control wobble on rotating shafts

- Concentricity (used carefully; can be hard to inspect)

- Position for cross holes relative to a turned datum

- Cylindricity for sealing surfaces

- Perpendicularity for faces that seat against mating parts

Reference standard: ASME Y14.5 (widely used in US-based drawings) or ISO GD&T standards (e.g., ISO 1101).

3) Surface finish: specify Ra where it matters

Surface texture impacts sealing, wear, and appearance. Surface finish is commonly specified as Ra (roughness average) per ISO 4287/4288.

Typical guidance for CNC turned parts:

- Ra 3.2 µm: standard turned finish for many industrial parts

- Ra 1.6 µm: smoother finish for sliding fits, improved appearance

- Ra 0.8 µm or better: may require fine turning, optimized tooling, or additional processes (polish/grind)

Buyer tip: If a surface is a seal, bearing, or press-fit, label it clearly (e.g., “Seal surface: Ra ≤ 0.8 µm, no circumferential scratches”).

Secondary Operations & Surface Finishing for Turned Parts

Many projects don’t end at the lathe. A reliable supplier should offer (or manage) secondary steps so you don’t juggle multiple vendors.

Common add-ons for CNC turned parts:

- Deburring (manual + controlled methods depending on geometry)

- Ultrasonic cleaning (important for medical, pneumatics, or optical assemblies)

- Heat treatment (e.g., hardening/tempering for steel, aging for 17-4PH)

- Anodizing (Type II/III), passivation (e.g., ASTM A967 for stainless)

- Electroplating (zinc, nickel, chrome), black oxide

- Bead blasting, polishing, cosmetic finishing

- Laser marking for traceability/part IDs

Finishes can change dimensions. For example, anodizing and plating add thickness—so critical diameters may need masking or pre-compensation. We call this out during DFM so your CNC turned parts assemble correctly the first time.

DFM Tips: Reduce Cost, Lead Time, and Inspection Risk

Most purchasing delays happen because drawings are technically “complete” but not manufacturing-friendly. Here are proven DFM levers for CNC turned parts.

Design checklist (quick wins)

- Use standard bar sizes where possible (reduces material waste and lead time)

- Avoid ultra-thin walls on long parts (chatter + deformation risk)

- Minimize deep, narrow grooves (tool access + tool break risk)

- Prefer standard thread callouts (UNC/UNF per ASME B1.1, metric per ISO 965)

- Add chamfers/lead-ins for threads and press fits

- Don’t over-tolerance non-functional dimensions

- Clearly mark datums for coaxial or assembly-critical parts

When you should ask for a DFM review

Request a DFM review if you have:

- Multiple tight coaxial requirements (runout, concentricity, cylindricity)

- Very small features (micro-drills, tiny grooves)

- Mixed operations (turning + milling + finishing)

- Assembly sensitivity (seals, bearings, press fits)

A good DFM review doesn’t “push back” to be difficult—it prevents expensive rework and protects your delivery schedule for CNC turned parts.

Quality Control: How Consistent CNC Turned Parts Are Verified

Overseas buyers often ask the right question: “Can you make it?” The better question is: “Can you make it the same way, every time, and prove it?”

Standards and controls that matter

Professional suppliers typically structure their system around ISO 9001 principles:

- Document control (revision management)

- Calibration control for inspection tools

- Traceability from raw material to finished goods

- Defined inspection plans (FAI + in-process + final)

For certain industries you may also see requirements like IATF 16949 (automotive), AS9100 (aerospace), or ISO 13485 (medical). Even if your program doesn’t require certification, you can still request evidence of process discipline for your CNC turned parts.

A practical QC workflow (what we do on most orders)

- Contract review: confirm revision, material, finish, and critical characteristics

- Incoming material verification: grade check + certificates when required

- First Article Inspection (FAI): verify critical dimensions early, before full run

- In-process checks: controlled frequency on key features (diameters, threads, runout)

- Final inspection: dimensional + visual + finish checks; thread gauges as required

- Documentation: inspection report, material certs, finishing certs on request

- Packaging control: protect critical surfaces to prevent transit damage

Typical inspection equipment used for turned components

- Micrometers, bore gauges, height gauges

- Pin gauges, ring gauges, Go/No-Go thread gauges

- CMM (coordinate measuring machine) for GD&T verification

- Surface roughness tester (for Ra requirements)

Consistent inspection is what turns “made it once” into repeatable CNC turned parts you can trust in production.

How to Choose a CNC Turned Parts Manufacturer (Without Getting Burned)

If you’re evaluating a cnc turned parts manufacturer, prioritize capability + process control—not just a low unit price.

10 questions to ask any turned parts supplier

- What is your max/min turning diameter and length range?

- Do you have live tooling, Y-axis, sub-spindles, or Swiss turning if needed?

- What tolerances do you routinely hold, and how do you inspect them?

- Can you provide FAI reports and material certificates?

- How do you control burrs and edge breaks?

- Do you manage surface finishing in-house or through qualified partners?

- What’s your typical lead time for prototypes vs. production?

- How do you handle revision changes and approvals?

- Can you support mixed processes (turning + milling + 5-axis) to reduce suppliers?

- What are your packaging methods for scratch-sensitive surfaces?

A reliable turned parts manufacturer should answer clearly, show examples (inspection reports/photos), and proactively suggest DFM improvements.

Local vs overseas: “cnc turned parts manufacturer georgia” and other regional searches

If you’re searching for a cnc turned parts manufacturer georgia, you’re probably weighing a local shop against an overseas option. Both can be right—depending on your priorities.

Local advantages (e.g., Georgia or your region):

- Faster in-person communication

- Easier audits and on-site visits

- Potentially faster domestic shipping

Overseas advantages (with a proven supplier):

- Cost efficiency for complex machining + finishing bundles

- Scalability for higher volumes

- Broader process coverage in one supply chain

No matter the location, use the same decision lens: Can they control quality, document it, and communicate fast? That’s what protects your program when buying CNC turned parts.

RFQ Checklist for CNC Turned Parts (Copy/Paste Friendly)

A clean RFQ is the fastest way to get accurate pricing and avoid surprises.

Send these items with your RFQ

- 2D drawing (PDF) with revision, tolerances, GD&T, and notes

- 3D model (STEP/IGES preferred) if available

- Quantity (prototype qty + annual volume estimate if possible)

- Material grade + standard (ASTM/EN/ISO)

- Required surface finish (Ra) and cosmetic requirements

- Surface finishing spec (anodize, passivation, plating, etc.)

- Thread specs and standards (metric/UNC/UNF; class/fit)

- Special requirements: cleanliness, marking, RoHS/REACH, etc.

- Inspection needs: FAI, CMM report, full dimensional report, AQL sampling

- Delivery address + Incoterms if shipping internationally

Add these notes if you want better quotes

- Identify critical-to-function dimensions (helps reduce over-processing)

- Mention mating parts or assembly method (press fit, seal, torque requirements)

- Confirm acceptable alternates (e.g., 303 vs 304 for machinability)

When we receive a complete RFQ, we can usually return a fast quote plus DFM feedback—so your CNC turned parts hit tolerance and ship on schedule.

Common Problems in CNC Turned Parts (and How Good Shops Prevent Them)

Here are the issues that most often cause assembly headaches—and what a capable supplier does about them.

Burrs that cut seals or block assembly

Prevention: controlled deburring plan, correct toolpaths, edge-break callouts (e.g., “Break sharp edges 0.2–0.5 mm”), and final visual checks.

Out-of-round / taper on critical diameters

Prevention: stable workholding (collets/soft jaws), appropriate feeds/speeds, tool condition monitoring, in-process gauging.

Chatter marks and poor finish

Prevention: optimized cutting parameters, rigidity improvements, correct insert geometry, and specifying Ra only where needed.

Threads that fail gauges

Prevention: correct thread standard, controlled tool wear, Go/No-Go gauging, and clear callouts (e.g., M10×1.0-6H).

A supplier who anticipates these risks will deliver CNC turned parts that assemble smoothly—without “hand fitting” on your end.

FAQ: CNC Turned Parts (People Also Ask)

1) What tolerances can CNC turned parts hold?

Many production CNC turned parts hold ±0.05 mm as a general baseline, with tighter features (±0.01 mm or better) possible on critical diameters after review. Geometry and material matter.

2) What files should I send for a quote?

Send a PDF drawing (with revision) plus a STEP model if you have it. Clear tolerances and finish notes speed up quoting for CNC turned parts.

3) Can you make prototypes and then scale to production?

Yes. A good approach is prototype validation (small qty + FAI), then a controlled move to production with defined inspection frequency—keeping CNC turned parts consistent lot to lot.

4) How do you inspect threads?

We typically use calibrated Go/No-Go gauges (ring or plug), plus measurement methods when required. Thread standard and class/fit must be clearly stated.

5) Do you provide material certificates?

On request, we can provide material certificates (often EN 10204 3.1) and finishing certificates depending on the process—important for traceability.

6) When should I choose Swiss turning?

Swiss turning is ideal for small-diameter, high-volume parts with tight tolerances and long/slender proportions—common in connector-style CNC turned parts.

7) Can turned parts include milled flats or cross holes?

Yes. Turning centers with live tooling can combine turning and milling features in one setup, improving positional accuracy and reducing handling.

8) What surface finishes are available after turning?

Common options include anodizing, passivation, plating, bead blast, polish, and black oxide. Always consider dimensional impact on critical fits.

Conclusion

Buying CNC turned parts successfully comes down to a few controllable basics:

- Specify function-driven tolerances and clear GD&T

- Choose the right material and finish (with traceability when needed)

- Vet your supplier’s inspection capability and process discipline

- Send a complete RFQ so pricing and lead time are accurate

If you want a faster, lower-risk start: upload your drawings for a free DFM review. We’ll confirm manufacturability, recommend cost-saving tolerance/finish adjustments if appropriate, and quote your custom non-standard parts with a clear inspection plan.