The Ultimate Guide to CNC Quality Control: CMM, GD&T & Preventing Defects

By The CNMP Expert Team

In the world of precision manufacturing, a part that is 0.05mm out of tolerance is not a “part”—it is scrap metal.

For procurement managers and engineers, nothing is more frustrating than receiving a shipment of 1,000 parts, only to find that the screws don’t fit, the surface is scratched, or the flatness is warped. This stops your assembly line, burns your budget, and damages your reputation.

CNC Quality Control (QC) is not just about having an ISO certificate on the wall. It is a rigorous, data-driven process of verifying geometry, material chemistry, and cosmetic standards.

In this definitive guide, we pull back the curtain on our QC Lab. We will explore the advanced metrology equipment (like CMM) we use, but more importantly, we will dive deep into the Real-World CNC Quality Control Nightmares that buyers face—and how we solve them before they ever leave our factory.

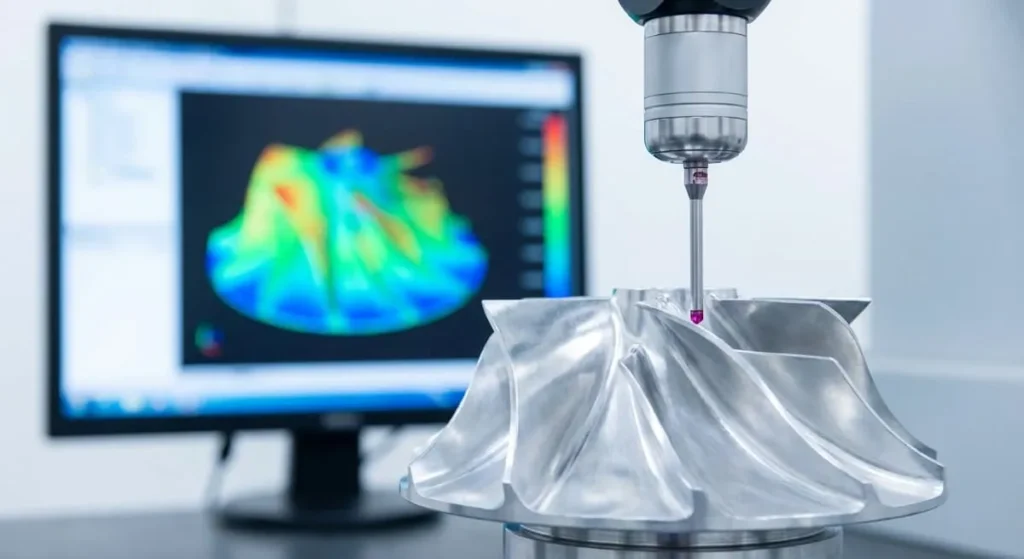

The “Supreme Court” of Measurement: The CMM

Why calipers are not enough.

For simple blocks, a hand caliper is fine. But for complex aerospace manifolds or medical implants with curved surfaces, you need the Coordinate Measuring Machine (CMM).

What is a CMM?

It is a massive granite table with a robotic probe. The probe touches the part at hundreds of specific points in 3D space.

- The Accuracy: It measures down to 0.001mm (1 micron). That is 50x thinner than a human hair.

- The Function: It compares the actual part geometry directly against your CAD model.

Why you need it:

If your drawing has GD&T (Geometric Dimensioning and Tolerancing) callouts like “True Position,” “Profile of a Surface,” or “Perpendicularity,” a human cannot measure this with a ruler. Only a CMM can mathematically calculate these abstract tolerances.

Expert Insight:

“At CNMP, every critical dimension is verified on our Zeiss or Hexagon CMM. We don’t guess; we prove the cnc quality control.”

Beyond the CMM: The Essential Metrology Toolbox

While the CMM is the star, a robust CNC quality control lab relies on a suite of specialized tools.

1. Optical Measurement Systems (Vision)

- What it does: Uses a high-resolution camera to measure small, flat parts instantly.

- Best For: Measuring tiny holes in PCBs, gaskets, or Plastic shims where a physical probe might deform the soft material.

2. Surface Roughness Tester (Profilometer)

- The Dispute: “This feels too rough.”

- The Solution: We don’t rely on feelings. We drag a diamond stylus across the surface to generate a numerical Ra value.

- Application: Verifying if a sealing surface meets the Ra 0.8 requirement for O-rings. (Reference: Bead Blasting vs Polishing)

3. Thread Gages (Go / No-Go)

- The Reality: 90% of machining failures are related to threads.

- The Tool: Hardened steel plugs (for holes) and rings (for shafts).

- The Rule: The “Go” gage must screw in easily. The “No-Go” gage must not enter. If either fails, the part is rejected.

The “House of Horrors”: Common Defects & Solutions(Part 1)

Real-world problems we see daily, and how we fix them by our cnc quality control.

This section addresses the specific pain points mentioned by our clients.

Nightmare #1: The “Tight Thread” After Plating

The Scenario: You receive zinc-plated steel standoffs. You try to screw them in, but they jam. The thread is too tight.

The Root Cause: The machinist cut the thread perfectly to the drawing before plating. But Electroplating adds thickness (e.g., 10 microns). That layer grows inward, shrinking the hole.

The CNC Quality Control Solution:

- Oversize Tapping: We must use special “oversized taps” (e.g., M6 +0.05mm) during machining. The part will feel loose when raw, but after plating adds the layer, it fits the Go/No-Go gage perfectly.

- Drawing Note: Always specify: “Dimensions apply AFTER plating.”

Nightmare #2: The “Banana” Part (Warping)

The Scenario: You ordered a long, thin aluminum base plate. When you place it on a flat table, it rocks back and forth. It’s bowed like a banana.

The Root Cause:

- Material Stress: Aluminum 6061 has internal stress. Removing the “skin” releases it.

- Clamping Force: The machinist clamped the vise too hard. The part was machined flat while squeezed, but sprang back when released.The Solution:

- Stress Relief: We rough-machine the part to within 1mm, then let it sit (or bake it) to release stress, then do a final light finishing pass.

- Soft Jaws / Vacuum Fixture: We use low-force holding methods for the final pass to prevent deformation.

The “House of Horrors”: Common Defects & Solutions (Part 2)

More real-world nightmares we prevent.

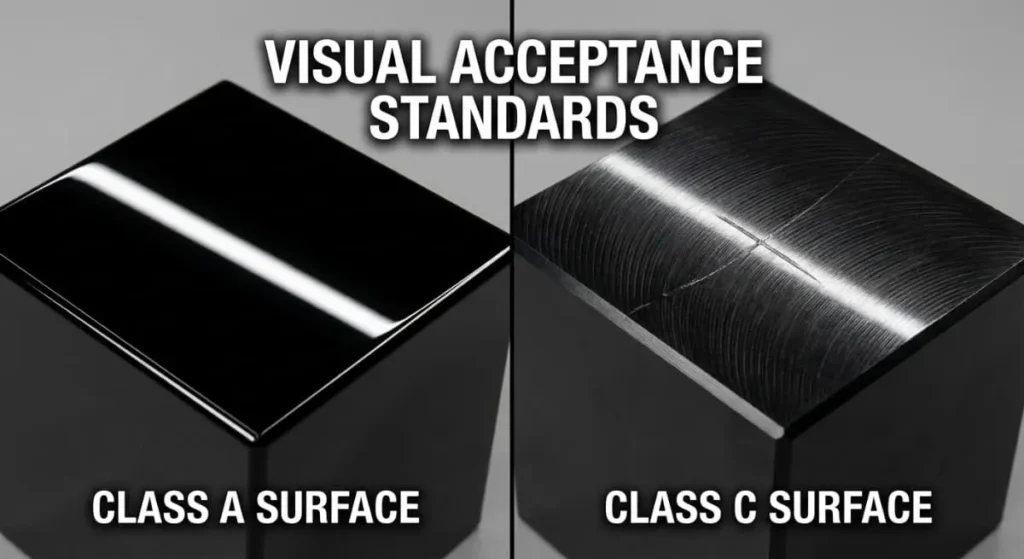

Nightmare: The “It Looks Bad” Dispute (Cosmetics)

The Scenario: You receive a batch of anodized parts. You hold them under a bright desk lamp and see tiny hairline scratches. You reject them. The factory argues: “These are within standard.” Who is right?

The Root Cause: “Good Appearance” is subjective. Without a standard, it’s just an opinion.

The CNC Quality Control Solution:

- Define the Surface Class: We encourage clients to specify cosmetic requirements based on visibility:

- Class A (Primary Visible): No defects visible from 18 inches away under normal lighting. (e.g., iPhone Case).

- Class B (Secondary): Minor scratches allowed if not felt by fingernail. (e.g., Inside of a case).

- Class C (Structural): Scratches and tool marks accepted. (e.g., Internal bracket).

- The Golden Sample: For critical projects, we create a “Limit Sample”—the worst acceptable part—and both sides sign it.

Nightmare: The Hidden Burr (The System Killer)

The Scenario: You install a hydraulic manifold. It works for an hour, then the valve jams. You take it apart and find a tiny sliver of metal stuck in the seal.

The Root Cause: Cross-hole Deburring. When two drilled holes intersect inside a block, they create a sharp, ragged edge (burr) deep inside where no tool can reach.

The CNC Quality Control Solution:

- Thermal Deburring: We place parts in a pressurized chamber and ignite a gas mixture. The heat wave instantly vaporizes the thin burrs without changing the part dimensions.

- Borescope Inspection: Our QC team uses endoscopic cameras to inspect internal intersections.

Nightmare: The Mystery Material (Fake Metal)

The Scenario: You ordered Stainless Steel 316 for a marine application. Six months later, it rusts. It turns out the factory used cheaper 304 Stainless.

The Root Cause: 304 and 316 look exactly the same. You can’t tell by eye.

The CNC Quality Control Solution:

- PMI Testing (Positive Material Identification): We use a handheld XRF (X-Ray Fluorescence) Gun. It shoots X-rays at the metal and gives a digital readout of the chemical composition (Cr, Ni, Mo) in seconds.

- The Promise: We include an XRF report with every shipment of premium alloys.

The Paper Trail: Why Documentation Matters

The “Birth Certificate” of your parts.

CNC Quality Control is not just about the metal; it’s about the data. At CNMP, we provide a full documentation package to ensure traceability.

1. FAI (First Article Inspection)

Before we run 1,000 parts, we make one.

- The Report: We measure every single dimension on the drawing (e.g., 50 dimensions) and record the actual values.

- The Rule: We do not start mass production until you review and approve the FAI report. This prevents the “1,000 wrong parts” disaster.

2. Material Certs (Mill Test Reports)

This document traces the metal back to the original steel mill where it was melted. It proves the heat number and chemical analysis.

3. CoC (Certificate of Conformance)

A legal document signed by our CNC Quality Control Manager certifying that the parts meet all specifications and are free from defects.

Summary: The CNMP CNC Quality Control Promise

CNC Quality Control is the difference between a “Machining Shop” and a “Manufacturing Partner.”

A shop just cuts metal. A partner worries about your thread fitment after plating, defines cosmetic standards before cutting, and proves the material chemistry with X-rays.

At CNMP, we don’t just inspect quality into the part at the end; we engineer defects out of the process from the start.

Stop gambling with your supply chain.

Contact our CNC Quality Contorl Team to review your drawings and discuss your specific inspection requirements.