Introduction: Why Prototypes Fail (and What a cnc prototyping service Must Control)

A prototype rarely fails because “CNC machining is inaccurate.” It fails because requirements are unclear, the design is not manufacturable at the requested time/cost, inspection expectations are ambiguous, or the supplier’s revision and process controls are weak. A cnc prototyping service reduces these failure modes by combining fast machining capacity with engineering review, measurable quality control, and documentation that makes problems resolvable.

Engineers want parts that validate fit, function, and performance. Procurement wants predictable lead time, controlled risk, and records that can be audited. The right cnc prototyping service supports both by turning CAD + drawings into parts with stable datums, defined tolerances, controlled material, and clear acceptance criteria.

This guide is built for real use: decision tables, copy/paste tools, and PO-ready clauses you can enforce with any cnc prototyping service.

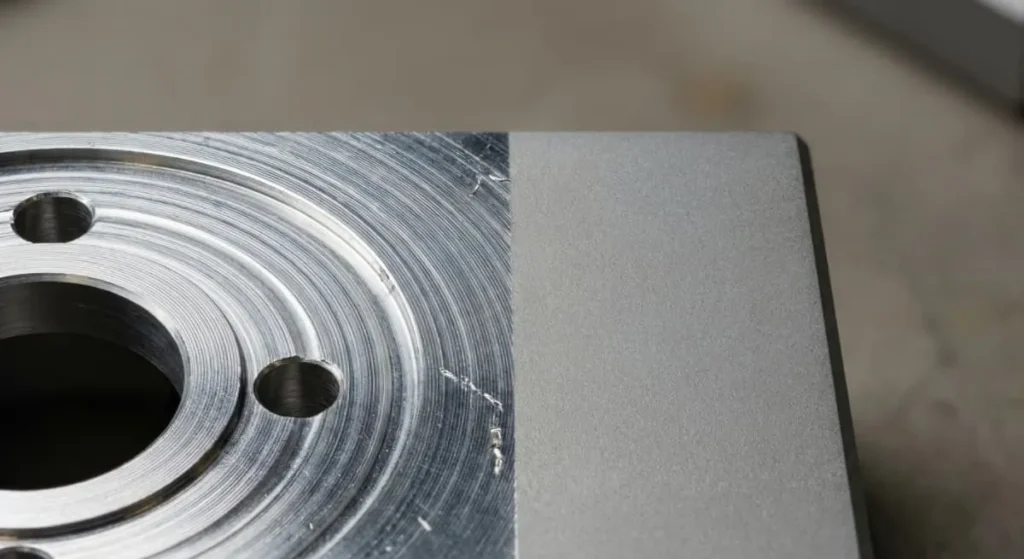

Engineering prototype sample: raw machined surfaces and tool marks help validate form, fit, and function before production.1) What a cnc prototyping service Is (and Is Not)

A cnc prototyping service produces prototype parts by subtractive machining (milling, turning, and sometimes 5-axis machining) based on your CAD model and drawing requirements. The goal is not only “a part that looks right,” but a part that behaves like production material and supports functional testing, assembly checks, and iteration.

What a cnc prototyping service usually includes

- Quoting from CAD + drawings, with clarifying questions and written assumptions

- DFM (design for manufacturability) feedback to reduce risk, lead time, and cost

- Rapid machining for single parts and small batches

- Optional finishing (anodize, passivation, bead blast, coating, etc.)

- Inspection options (dimensional report, FAI, CMM report)

- Packaging and shipping appropriate for prototypes and small lots

What a cnc prototyping service should not be

- A “black box” that will not explain measurement datums, assumptions, or inspection scope

- A quote that hides revision rules, inspection scope, or finishing lead time

- A workflow that depends on luck (or heroics) instead of documented controls

If you treat prototyping like an informal purchase, you often get informal outcomes. If you treat it like a controlled engineering handoff, a cnc prototyping service becomes a predictable accelerator.

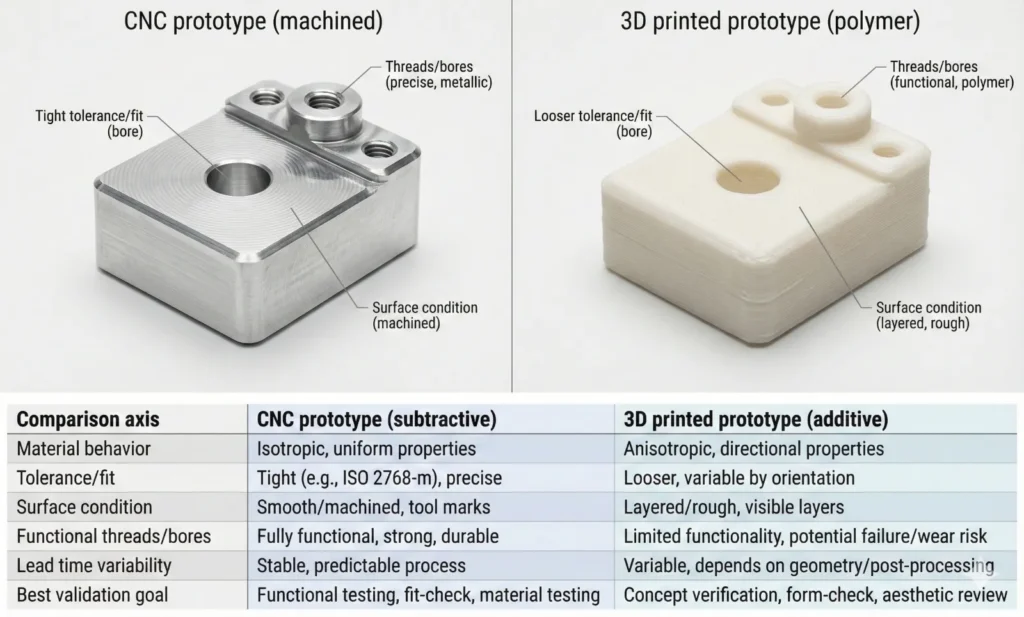

2) CNC vs 3D Printing for Prototypes (Decision Table)

3D printing excels for early geometry checks, ergonomic models, and fast concept iteration when material behavior is not the learning objective. CNC machining is often the better choice when material properties, tight interfaces, or production-intent finishes matter. In those cases, a cnc prototyping service is usually the safer path.

CNC vs 3D printing: decision table

| Decision factor | CNC machining (via cnc prototyping service) | 3D printing |

|---|---|---|

| Mechanical properties | Production-like metals and engineering plastics | Often anisotropic; depends on process |

| Tolerances and fit | Strong for bores, threads, mating features | Often limited; post-processing may be needed |

| Surface finish | Machined + production-like finishing options | Layer texture; finishing can be labor-intensive |

| Geometry freedom | Limited by tool access and fixturing | Very high (internal channels, complex cavities) |

| Best use case | Functional prototypes, assemblies, pilot builds | Concept models, early form/space validation |

Use CNC when validation depends on material behavior and precise interfaces; use 3D printing when learning is primarily shape and space.Practical rule: if learning depends on threads, bores, sealing faces, bearing seats, or positional relationships, start with a cnc prototyping service. If learning is primarily “shape and space,” 3D printing may win on speed and cost.

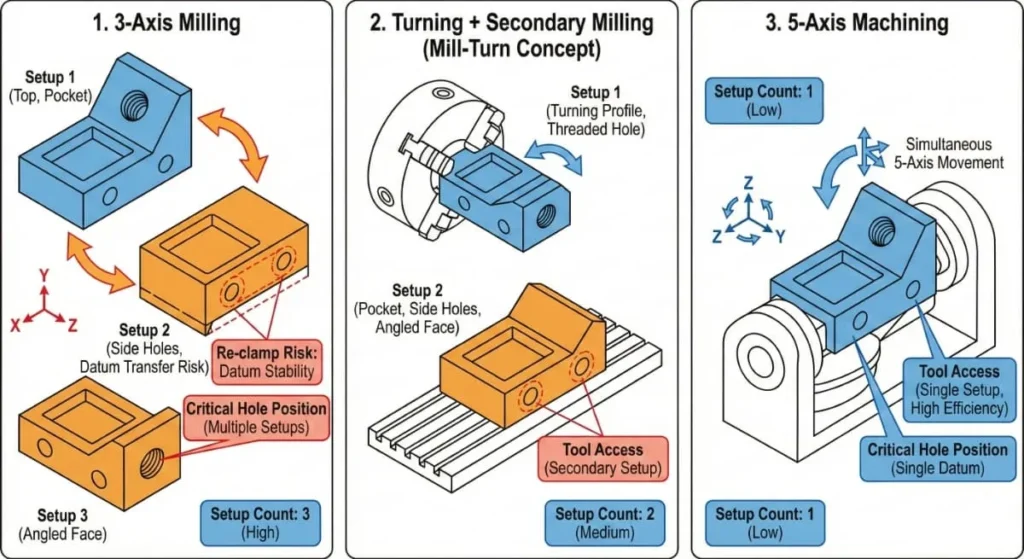

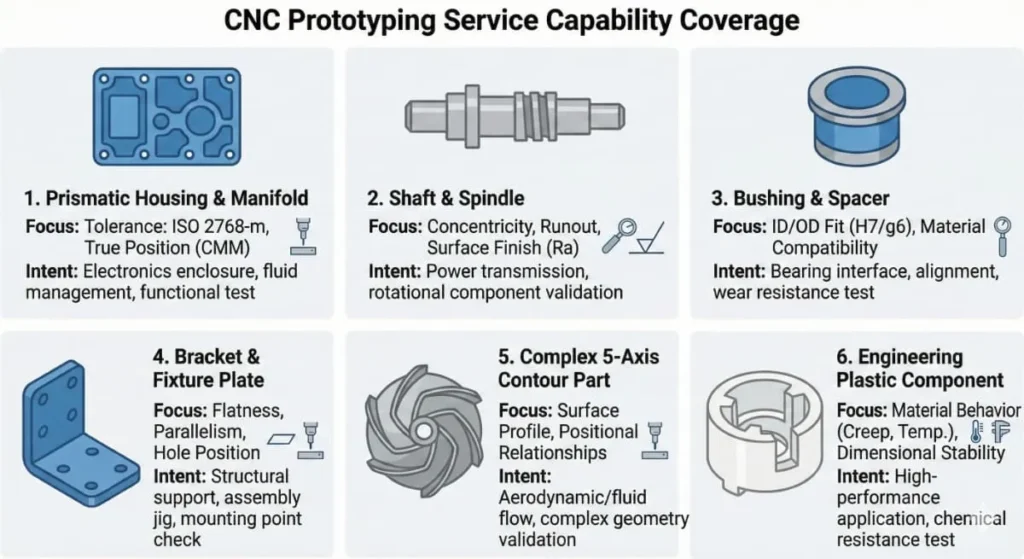

3) Process Selection: Milling vs Turning vs 5-Axis

Process choice is one of the biggest levers for cost, lead time, and quality. A capable cnc prototyping service will recommend the process that reduces setups, stabilizes datums, and minimizes re-clamping error.

3.1 Milling vs Turning (Procurement-Friendly Comparison)

| Topic | CNC milling | CNC turning |

|---|---|---|

| Best geometry | Prismatic parts, pockets, flats | Cylindrical/rotational parts |

| Typical parts | Brackets, housings, plates, heat sinks | Shafts, bushings, spacers, pins |

| Cost drivers | Multiple setups, long toolpaths | Secondary ops (flats, cross holes, milling features) |

| Common quality risk | Re-clamping positional error between setups | Datum confusion once secondary ops start |

| Where it shines | Flexible feature creation | Concentricity and round features efficiently |

Same reference part, three process plans: fewer setups usually improves datum stability and reduces re-clamp risk.3.2 When 5-Axis Is Worth It

5-axis machining can reduce setups dramatically. Fewer setups often means better positional accuracy, fewer handling marks, and faster delivery for complex parts. A cnc prototyping service may recommend 5-axis when:

- Features on multiple faces require tight positional relationships

- Angled features would otherwise require multiple re-clamps

- Smooth 3D contours need consistent surface quality

- You want to reduce stack-up error across operations

3.3 Process Selection Rules You Can Use in Sourcing

Use these rules to compare quotes from any cnc prototyping service:

- Minimize setups first; optimize cycle time second. Setups create risk and delay.

- Keep critical datums stable across operations. Ask how the part will be located and re-located.

- Choose turning when roundness/concentricity dominates function.

- Choose 5-axis when it removes re-clamping for more than two orientations.

- If the supplier cannot explain the process plan and inspection approach, treat the quote as unknown risk, not low cost.

Related reading (internal links you can publish and link from this page)

- CNC milling basics (process, cost drivers, DFM)

- CNC turning basics (concentricity, threads, runout risks)

- 5-axis machining overview (when it reduces total cost)

4) Materials for CNC Prototypes + Documentation to Request

Material selection should reflect the test you intend to run. A cnc prototyping service is most valuable when it helps you choose a material that matches the final environment without overpaying for unnecessary performance.

4.1 Common Metals (Prototype Workhorses)

- Aluminum 6061 / 7075: excellent machinability and availability. 7075 for higher strength; 6061 for broad stock and forgiving processing.

- Stainless steel 303/304/316: corrosion resistance and strength; typically higher cost and longer machining time. Plan inspection carefully.

- Brass / Copper: conductivity and appearance; copper can be gummy, brass typically machines cleanly.

- Titanium Grade 2 / Grade 5: high performance with higher machining complexity; requires realistic lead time and cutting strategy.

4.2 Engineering Plastics (When You Need Polymer Behavior)

- POM/Acetal (Delrin): stable, low friction, good for sliding interfaces

- ABS: practical for housings, fixtures, general functional prototypes

- Nylon: tough and wear-resistant; moisture sensitivity can affect dimensions

- PEEK: high temperature and chemical resistance; higher cost and longer sourcing lead time

4.3 Material Documentation (Procurement Checklist)

If traceability or compliance matters, require your cnc prototyping service to state what it will provide:

- MTR/MTC (Material Test Report/Certificate): material grade, chemistry, heat/lot

- CoC (Certificate of Conformance): statement that material/processing meets PO requirements

- Lot traceability: ability to link delivered parts to heat/lot (labeling, packing list linkage)

- Special process certificates: anodize/plating/heat treat certificates (if applicable)

If a supplier cannot provide the documentation you need, the risk is not only quality risk; it is also commercialization risk (you may not be able to use the prototype data to advance to the next gate).

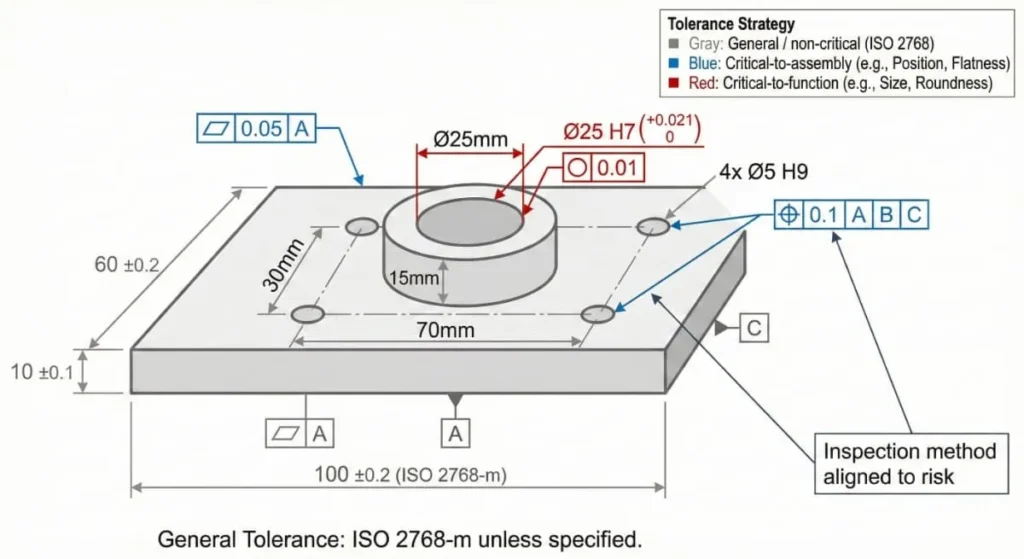

5) Tolerances, GD&T, Surface Finish, and What to Measure (ISO 2768)

Tolerances drive machining strategy and inspection scope. The most common mistake is applying “tight everywhere” tolerances without identifying which features are critical. A cnc prototyping service can be fast and predictable only when critical features are explicit.

5.1 Use Tolerance Tiers (Instead of One “Magic Number”)

| Tier | Typical use | What to specify | Why it helps a cnc prototyping service |

|---|---|---|---|

| General (non-critical) | Most features | General tolerance standard (often ISO 2768) | Reduces drawing clutter and cost |

| Critical-to-assembly | Mating faces, hole patterns | Explicit +/- or GD&T tied to assembly intent | Focuses machining/inspection where it matters |

| Critical-to-function | Seals, bearing seats, flow paths | Tight tolerance + inspection method | Aligns metrology and process plan to risk |

Tier tolerancing helps align machining effort and inspection scope: general ISO 2768 + focused GD&T on critical interfaces.Good practice: use ISO 2768 (or your preferred standard) for general features and reserve tight tolerances for functional and assembly-critical interfaces. This is one of the fastest ways to improve outcomes with a cnc prototyping service.

5.2 GD&T: Use It to Reduce Ambiguity, Not Increase It

GD&T is powerful when it expresses functional intent and datums clearly. It becomes expensive and dispute-prone when datums are missing or unrealistic. When working with a cnc prototyping service:

- Define primary/secondary/tertiary datums that match assembly and measurement

- Put true position on hole patterns that actually drive assembly

- Use flatness/perpendicularity where it stabilizes functional faces

- Avoid over-constraining everything (cost and rework risk rise)

5.3 Surface Finish: Specify Only What Matters

Surface finish affects friction, sealing, aesthetics, and coating adhesion. It also affects lead time and price at a cnc prototyping service. Common finishes:

- As-machined: fastest; visible tool marks may remain

- Bead blasting: uniform matte texture; hides tool marks

- Anodizing Type II / Type III: aluminum protection; Type III for wear resistance

- Passivation: corrosion resistance improvement for stainless steel

- Powder coating/painting: durable aesthetics; define masking and thickness concerns

If you care about Ra, specify a target value and define zones. If you do not, keep finish requirements simple to reduce cost and ambiguity.

Surface finishes affect fit, sealing, appearance, and coating adhesion—define finish zones early to avoid rework.6) Inspection Deliverables Explained (FAI, CMM Reports) + Sampling Plan

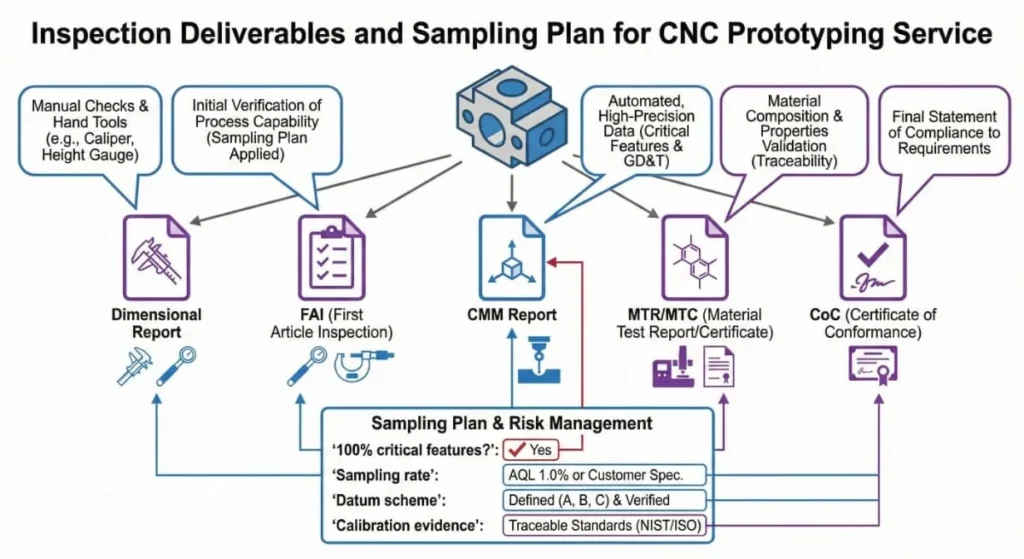

Inspection is not a checkbox. It is scope, method, datums, and records. A cnc prototyping service should quote inspection deliverables explicitly, and procurement should tie acceptance to those deliverables.

6.1 What Each Inspection Deliverable Proves

| Deliverable | What it proves | When to request it from a cnc prototyping service | Notes |

|---|---|---|---|

| Dimensional report | Listed dimensions were measured | Most prototype orders | Clarify sampling vs 100% |

| FAI (First Article Inspection) | First-piece verification to drawing | First build or revision change | Great for repeatability |

| CMM report | High-accuracy measurement for GD&T | Tight GD&T/complex geometry | Ask for datum scheme/method |

| MTR/MTC | Material grade and heat/lot traceability | Automotive/regulated/critical parts | Confirm linkage to parts |

| CoC | Supplier conformance statement | Common procurement requirement | Useful for audits |

Make acceptance measurable: tie critical features to an inspection deliverable (FAI/CMM) and define sampling and datum scheme.6.2 Sampling Plan: Questions That Prevent Disputes

Before cutting metal, ask your cnc prototyping service:

- Are critical dimensions 100% inspected or sampled?

- What measurement method is used for each critical feature (calipers, bore gage, pin gage, CMM, surface tester)?

- How are datums established during measurement?

- Are measurement tools calibrated, and can evidence be provided?

Many prototype disputes are not “out of tolerance” disputes. They are “measured differently” disputes. Sampling and datum language prevents that.

7) DFM Checklist: Reduce Cost and Lead Time Without Gambling Quality

DFM is where you save the most time. A cnc prototyping service can machine extremely complex parts, but cost and lead time rise quickly when tool access is poor, setups multiply, or tolerances are unnecessarily tight.

7.1 Pockets and Tool Access

- Avoid deep, narrow pockets when possible. Long tools chatter and slow cycle time.

- Prefer open-ended pockets and larger corner radii so larger tools can be used.

- Ask what tool diameter the cnc prototyping service assumes for internal features.

7.2 Internal Corners and Radii

- Add fillets to internal corners (cutters are round).

- If a sharp internal corner is functionally required, discuss options (EDM, reliefs, design changes) early.

7.3 Thin Walls and Slender Features

- Thin walls can warp or vibrate; define which faces are cosmetic vs functional.

- Long slender features may require alternate process planning; a good cnc prototyping service will flag these as risk items and propose mitigation.

7.4 Holes, Threads, and Critical Bores

- Standardize hole sizes to common drills/reamers.

- Specify thread class and engagement requirements.

- For critical bores, consider reaming/boring and specify the inspection method you want.

7.5 Tolerance Discipline (Highest ROI)

- Tight tolerances only on critical features.

- Use ISO 2768 for general tolerances where appropriate.

- Label “critical-to-function” and “critical-to-assembly” on the drawing so the cnc prototyping service can align machining and inspection to risk.

8) Lead Time Model + Logistics Planning

Lead time is not just machining hours. It includes quoting, DFM turnaround, scheduling, finishing, inspection, and shipping. A cnc prototyping service should break lead time into components you can manage.

8.1 Typical Lead Time Breakdown

- RFQ review + questions: same day to 1 day

- DFM feedback + quote: 1–2 days

- Programming + fixturing + machining: 1–7 days (complexity-dependent)

- Finishing: 0–10 days (process-dependent)

- Inspection + reporting: 0–2 days (scope-dependent)

- Shipping + customs: 1–7 days (route-dependent)

When comparing suppliers, ask for the lead time with each component stated. A cnc prototyping service that cannot separate these stages often cannot control them.

9) Cost Drivers and How to Reduce Them Safely

Prototype cost is rarely only “machine time.” The main cost drivers in a cnc prototyping service quote are setups, programming complexity, inspection scope, finishing, and schedule priority.

9.1 Primary Cost Drivers

- Setups and re-clamping: more orientations = more labor and more risk

- Cycle time: complex geometry, fine stepovers, tool changes

- Tight tolerances and GD&T: slower machining and more metrology time

- Material: exotic alloys/high-performance plastics can extend sourcing time

- Finishing: masking, thickness control, secondary processes add days

- Inspection deliverables: FAI/CMM requires time, equipment, and reporting

9.2 Cost Reduction Strategies That Preserve Quality

Use these approaches with your cnc prototyping service to reduce total cost without buying hidden risk:

- Reduce setups by adjusting geometry or allowing 5-axis.

- Move non-critical features to general tolerance (ISO 2768 where appropriate).

- Standardize holes and thread specs.

- Specify finish only where it is functional or customer-facing.

- Define inspection scope so the quote is accurate and acceptance is objective.

Cheapest is not the same as lowest total cost. A delayed or unusable prototype is often the most expensive outcome.

10) Supplier Vetting: Audit-Style Questions Procurement Should Ask

Procurement success is selecting a cnc prototyping service that can deliver repeatedly, with documentation that makes issues resolvable.

10.1 Quality System and Change Control

Ask your cnc prototyping service:

- Do you have ISO 9001 certification, or operate under a documented QMS?

- How do you control revisions and prevent machining outdated files?

- What is your nonconformance process (containment, rework/remake, corrective action)?

10.2 Process Transparency (Evidence, Not Promises)

Request from the cnc prototyping service:

- Process plan summary: machine type, number of setups, datum strategy

- Example inspection reports (anonymized) showing datum usage and measurement method

- Calibration management approach for key metrology tools

10.3 Communication and Assumption Discipline

A reliable cnc prototyping service asks clarifying questions early, documents assumptions in the quote, and provides written DFM notes. A supplier that accepts everything without questions often postpones the risk until after machining.

11) The Deliverables Matrix (What “Comes in the Box”)

Unclear deliverables create procurement disputes and engineering rework. This matrix makes scope explicit so a cnc prototyping service can quote accurately and you can accept parts objectively.

Deliverables Matrix (tiered)

| Deliverable item | Standard Prototype (speed & cost focus) | Precision / Pre-Production (validation focus) |

|---|---|---|

| Dimensional report | Critical dimensions check (example: 3–5 key features) | Full CMM report and/or FAI package (scope defined) |

| Material certification | CoC (basic statement of conformance) | MTR/MTC with heat/lot traceability (if required) |

| Surface finish | Deburr + as-machined (unless specified) | Certified Ra/Rz zones + masking plan (if required) |

| Photos/updates | Shipping confirmation photos | In-process photo updates at agreed milestones |

| Packaging | Bulk protection suitable for prototypes | Individual bagging/tray packing + labeling for assembly |

| Support | Standard DFM notes | Named engineering contact + structured issue handling |

Operational tip: choose a deliverables tier in every RFQ and PO. If you do not specify, the cnc prototyping service will guess, and you may receive less documentation than your program needs.

12) PO-Ready Acceptance Criteria (Copy/Paste)

These clauses convert a cnc prototyping service order into measurable outcomes. Customize the bracketed fields for your PO.

12.1 Drawing, Revision, and Assumption Control

- Supplier shall manufacture to: [Part Number] Rev [X], per attached drawing/CAD.

- Any ambiguity or missing requirement shall be clarified in writing before machining; assumptions must be documented in the quote/acknowledgment by the cnc prototyping service.

- No substitution of material grade/temper or specified finish without written approval from buyer.

12.2 Dimensional Acceptance (Tie to Inspection Scope)

Select one option and include it on the PO:

- Option A (Critical Features 100%): Measure and report PO-listed critical features at 100% of parts; remaining features per drawing and general tolerance standard (e.g., ISO 2768 where specified).

- Option B (FAI-Based): Provide an FAI report for the first completed part; remaining parts inspected per agreed sampling plan.

- Option C (CMM-Based): Provide a CMM report for listed GD&T and critical-to-function features using drawing datums and stated measurement method.

Include a line such as:

- Critical acceptance features: [list 3–10 features with tolerances and datum references].

12.3 Surface Finish Acceptance

- If Ra is specified: supplier shall provide Ra measurement results for specified zones and state measurement method.

- If cosmetic zones exist: buyer shall identify zones and acceptable defect limits on drawing; supplier shall package to prevent cosmetic damage.

12.4 Material and Traceability Acceptance

- If required: supplier shall provide MTR/MTC showing material grade and heat/lot number; heat/lot must be traceable to delivered parts (labeling or packing list linkage).

- Supplier shall provide CoC for material and special processes as required by the PO.

12.5 Special Process and Sub-Supplier Certificates (If Applicable)

- For anodize/plating/heat treat: supplier shall provide process certificates meeting PO requirements (type, thickness, spec, color).

- If sub-suppliers are used by the cnc prototyping service, certificates must match PO requirements and be included in the delivery package.

12.6 Packaging and Labeling Acceptance

- Parts shall be packaged to prevent part-to-part contact and transit damage.

- Labels shall include: [Part Number], [Revision], [Quantity], and [Lot/Heat] if traceability is required.

12.7 Nonconformance Handling

- Supplier shall notify buyer within [24–48 hours] after discovering any nonconformance.

- Supplier shall provide containment and corrective action response within [5–10 business days] when requested (8D format if required).

- Rework/remake authorization and logistics responsibility must be agreed in writing.

These clauses make acceptance objective and reduce disputes with a cnc prototyping service.

13) Automotive & Regulated Sourcing Addendum (Pre-PPAP, IMDS, 8D)

If prototypes feed an automotive or regulated program, add expectations early. Even if you are not doing full PPAP at prototype stage, you should align documentation so the path to production is not blocked later.

13.1 Automotive: Prototype to Pre-PPAP Readiness

A cnc prototyping service supporting automotive R&D should be able to support, when required:

- Traceability: material heat/lot linkage and controlled records

- Change control: revision history and ECO/ECN handling

- Dimensional results aligned to future PPAP expectations (scope defined)

- Structured problem solving: containment + corrective action, often in 8D format

13.2 IMDS Considerations

If your customer requires IMDS, confirm early what the cnc prototyping service will provide for material declarations (often tied to MTR/MTC and special-process certificates) and whether IMDS entry support is in scope.

13.3 Regulated Programs (Medical/Aerospace-Style Expectations)

Depending on your flowdowns, you may require:

- Enhanced cleanliness or contamination controls

- Documentation retention periods and controlled access

- Compliance declarations (e.g., RoHS/REACH if applicable to your program)

14) RFQ Checklist + Copy/Paste RFQ Template

This section improves quote accuracy and reduces assumption risk for any cnc prototyping service.

14.1 RFQ Checklist (3 Tiers)

Tier A (required)

- 3D CAD: STEP/IGES

- 2D drawing: critical dimensions, datums, GD&T, threads, finish notes

- Material: grade/temper + heat treat (if applicable)

- Quantity: prototype qty + expected follow-on qty (if relevant)

- Finish: specify or state “as-machined”

- Target delivery date + ship-to address

- Revision identifier (part number + revision)

Tier B (strongly recommended)

- Label “critical-to-function” / “critical-to-assembly” features

- General tolerance standard (often ISO 2768) for unspecified dimensions

- Cosmetic zones and acceptable defect limits

- Inspection scope: dimensional/FAI/CMM + sampling plan

- Packaging requirements: separation, labeling, VCI/protective film if needed

Tier C (program-specific)

- Traceability requirements: MTR/MTC + lot tracking

- Required documents: CoC and special-process certificates

- Change control expectations: ECO/ECN

- Compliance requirements as applicable

14.2 Copy/Paste RFQ Template

Subject: RFQ — CNC Prototype [PART NO] Rev [X] — Qty [QTY]

Hello,

Please quote manufacturing for the attached CAD and drawing.

- Process requested: CNC machining (supplier to recommend milling/turning/5-axis as needed)

- Quantity: [QTY] prototypes (future volume estimate: [QTY/year] if relevant)

- Material: [e.g., 6061-T6 / 7075-T6 / 316 / POM / PEEK]

- Finish: [as-machined / bead blast / anodize type + color / passivation / coating]

- General tolerances: [e.g., ISO 2768-m unless otherwise specified]

- Critical features: [list 3–10 key features + tolerances + datums]

- Inspection deliverables: [dimensional report / FAI / CMM] + [sampling plan]

- Documentation: [CoC / MTR/MTC / process certs as required]

- Packaging/labeling: [requirements]

- Ship to: [address]

- Target delivery: [date]

Please include: unit price, lead time breakdown (machining/finish/inspection/shipping), assumptions, and DFM recommendations.

Thank you,

[Name / Company / Phone / Email]

This format helps a cnc prototyping service quote faster and reduces back-and-forth.

15) FAQ (People Also Ask Style)

Q1: How fast can a cnc prototyping service deliver parts?

Most prototypes ship in days to a couple of weeks depending on complexity, finishing, and inspection scope. Ask for a lead time breakdown (DFM/quote, machining, finishing, inspection, shipping) so you can manage schedule risk with the cnc prototyping service.

Q2: What files should I send to a cnc prototyping service?

Send a 3D CAD file (STEP/IGES) plus a 2D drawing (PDF) defining critical dimensions, datums, GD&T, threads, and finish notes. Without the drawing, the cnc prototyping service must guess what matters.

Q3: Should I request a CMM report for prototypes?

Request a CMM report when geometry is complex, GD&T matters, or critical relationships drive function/assembly. For simpler parts, a targeted dimensional report may be enough; the cnc prototyping service should help match inspection scope to risk.

Q4: What is the biggest mistake buyers make with a cnc prototyping service?

Over-tolerancing and under-communicating. If everything is tight and nothing is labeled critical, the cnc prototyping service must either over-price the job or gamble on what matters.

Q5: How do I compare two cnc prototyping service quotes beyond price?

Compare number of setups, stated assumptions, inspection scope, deliverables (FAI/CMM/MTR), finishing lead time, revision control process, and responsiveness to clarifying questions.

Q6: Can a cnc prototyping service scale from prototype to low-volume production?

Often yes, if the supplier preserves programming data, datum strategy, and an inspection plan. Ask how the cnc prototyping service handles ECO/ECN changes and maintains consistency across batches.

16) References & Standards (Verification)

- ISO 9001: Quality management systems — Requirements

- ISO 2768-1: General tolerances for linear and angular dimensions without individual tolerance indications

- ASME Y14.5: Dimensioning and tolerancing (GD&T)

- ASTM standards: material verification and testing methods (as applicable to your material/spec)

Next Step (Simple and High-Conversion, Not Pushy)

If you want fewer surprises from any cnc prototyping service, do three things in your next RFQ:

- Label critical features (critical-to-function vs critical-to-assembly).

- Choose an inspection tier (dimensional / FAI / CMM) and define sampling.

- Choose a deliverables tier (standard prototype vs precision / pre-production) and paste the acceptance criteria into the PO.

Contact CNMP Team,you will get more information you want.