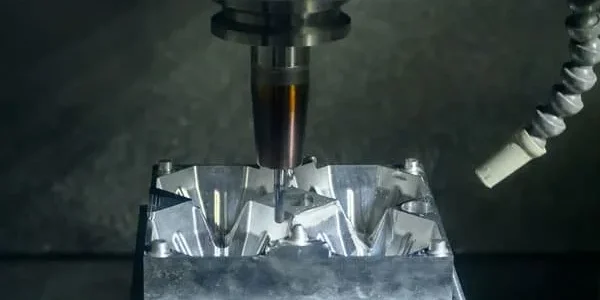

CNC Milling Services

High-precision CNC milling services for metal and plastic parts with tight tolerances, fast lead times, and material flexibility. Ideal for prototypes and low- to high-volume production.

What is CNC Milling?

CNC milling is a subtractive manufacturing process that uses computer-controlled rotating cutting tools to remove material from a solid workpiece. It is commonly used to produce complex parts with precise dimensions and surface finishes.

In a typical CNC milling service, the part is designed in CAD software and then converted into machine-readable instructions. These instructions guide the movement of the tool and the workpiece across multiple axes, allowing for consistent production of parts with tight tolerances.

There are several variations of this process depending on complexity. 3-Axis CNC milling is the most widely used and ideal for most simple to moderately complex parts. For more intricate geometries or multi-sided machining, 4-axis and 5-axis setups are available.

CNC milling is not limited to metal. It’s also widely used for plastic CNC milling parts, wood prototypes, and even foam patterns. In some cases, people refer to it as CNC router service, especially when dealing with softer materials or wood.

Whether you’re creating mechanical brackets, housings, manifolds, or enclosures, custom CNC milling provides a flexible solution for both prototyping and low-volume production runs.

CNMP’s CNC Milling Capabilities

Precision. Complexity. Versatility — Discover what our milling centers can achieve.

3-Axis & 4-Axis CNC Milling Services

Our facilities are equipped with advanced 3-axis and 4-axis CNC milling machines that can produce parts with high accuracy and repeatability. This setup is ideal for flat and prismatic components and allows us to mill parts for automotive, aerospace, and industrial applications.

Max travel: 1000mm x 600mm x 500mm

Tolerance: ±0.01 mm

Materials: Aluminum, Steel, Brass, Plastics

Complex Geometry Milling

For parts requiring undercuts, curved profiles, and complex surface machining, our 4-axis capabilities support simultaneous multi-surface milling. We help customers reduce multiple setups, saving time and cost.

Ideal for: CNC router parts, electronics housings, fixtures

Surface finish options: Ra 0.8–3.2 μm

Small-Batch & Prototyping Flexibility

Whether it’s a one-off prototype or a low-volume production run, our CNC milling services adapt to your needs. We support rapid changes in design and flexible delivery.

File formats supported: STEP, IGES, STL,STP,DWG,PDF…

Lead time: 3–7 business days

Tolerances & Inspection

We meet tight tolerances and validate each part with calibrated tools and CMM inspection if required.

Standard tolerance: ±0.01 mm

Optional: ±0.005 mm (upon request)

Documentation: Inspection report, material certificate (if needed)

Materials We Work With

Understanding Material Challenges in CNC Milling Services

Selecting the right material is one of the most common challenges faced by customers looking for CNC milling services. The choice of material not only affects the machining process but also directly impacts part performance, cost, and delivery time. At CNMP, we handle a wide range of materials for CNC milling parts — from lightweight aluminum alloys to high-strength steels and engineering plastics — ensuring your design requirements are met without unnecessary trial and error.

Aluminium and Its Alloys

Why it’s commonly used:

Aluminium is one of the most popular materials for CNC milling services due to its excellent machinability, corrosion resistance, and balance of strength-to-weight ratio.

Typical customer challenge:

Many customers ask: “Which aluminium alloy is best for my part?” The answer often depends on whether the part needs higher strength, better surface finish, or improved corrosion resistance.

Commonly machined grades:

AL-6061-T6: Widely used for general CNC milling parts thanks to its strength and cost-effectiveness.

AL-7075: Preferred for aerospace and automotive CNC milling components where high strength is critical.

AL-2024: Strong, but less corrosion-resistant, often used in structural parts.

Specialty Materials

Why it’s important:

Specialty materials such as titanium alloys and high-performance composites are increasingly used in aerospace, medical devices, and advanced engineering. They combine strength, light weight, and extreme resistance to heat or corrosion, making them essential in high-demand industries.

Common challenge:

Customers often face concerns about machinability, tool life, and achieving tight tolerances when working with these materials. Understanding the right tooling and process adjustments is key to balancing quality with efficiency.

Common materials we machine:

Titanium (Ti-6Al-4V): High strength-to-weight ratio, excellent for aerospace and medical parts.

Inconel (Nickel Alloy): Exceptional heat resistance, commonly used in turbines and chemical processing.

Magnesium Alloys: Very lightweight, ideal for automotive and aerospace, but requires careful handling during machining.

Carbon Fiber Composites (CFRP): High strength and stiffness, widely applied in racing and drone structures.

Stainless Steel

Why it’s important:

Stainless steel provides durability, corrosion resistance, and good mechanical properties. It’s frequently used in CNC router parts for medical, industrial, and marine applications.

Common challenge:

Machining stainless steel often raises questions about cost and tool wear. Customers want to balance performance with efficiency.

Common grades we machine:

SS 304: Excellent corrosion resistance; commonly chosen for food and chemical industries.

SS 316: Better resistance to chemicals and saltwater; ideal for medical and marine use.

SS 303: Easier to machine compared to other stainless grades.

Carbon Steel and Alloy Steel

Why it matters:

For customers looking for stronger CNC milling parts, steels are often considered.

Common challenge:

The main concern is heat treatment compatibility and whether the part requires hardness or wear resistance after machining.

Examples:

Mild Steel (1018, 1045) for cost-effective general parts.

Tool Steel (D2, O1) for wear-resistant CNC milled tools and dies.

Brass and Copper

Why they’re selected:

Both brass and copper offer excellent machinability and electrical conductivity.

Customer problem:

Designers often wonder: “Can these soft materials maintain tight tolerances during CNC milling?” The answer is yes — but requires careful tooling and machining strategy.

Plastics and Composites

Why they’re growing in demand:

Plastics are lightweight, corrosion-free, and cost-effective for prototyping and low-volume CNC milling services.

Common challenges:

Warping during machining

Choosing the right plastic grade for durability vs flexibility

Examples we work with:

ABS, Nylon, POM (Delrin), PTFE (Teflon)

PEEK for high-performance, heat-resistant parts

Industries Served

CNC milling services is widely applied across diverse industries, each with its own requirements and challenges. Understanding these needs allows for better alignment between design expectations and manufacturing outcomes. Below are some of the typical industries where CNC milling plays a crucial role.

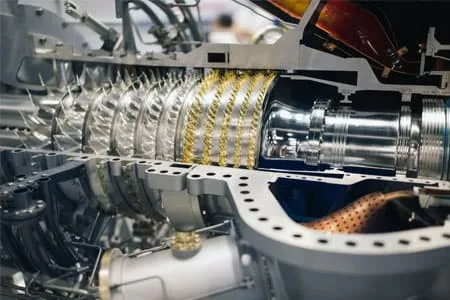

Aerospace

Extreme accuracy and material performance are the most critical. Customers often prioritize strength-to-weight ratio and tight tolerances for safety.

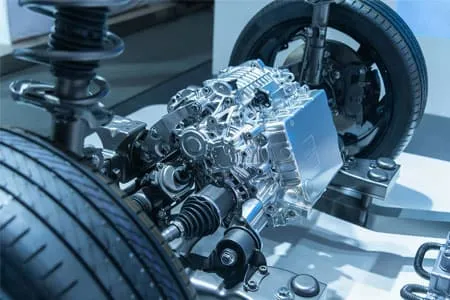

Automobiles

Efficiency and repeatability matter most. Customers seek consistent quality, cost-effectiveness, and the ability to scale production.

Water Engineering

Resistance to water, chemicals, and pressure over time. Customers are most concerned with material durability and long-term reliability

Electronics

Miniaturization and complexity. Customers worry about achieving dimensional accuracy for small components while ensuring heat dissipation or insulation.

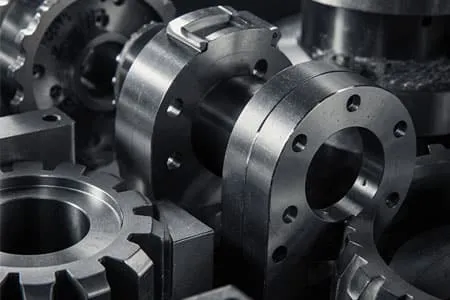

Industrial Equipment

Reliability and adaptability. Customers want large or complex parts that remain dimensionally stable under operational stress

Research Institutes & Laboratories

Flexibility and accuracy. Researchers focus on fast iterations across different materials without losing precision

CNC Milling Part Gallery

Visual examples of CNC milling parts help visitors understand the range of industries served and the machining capabilities available. Each part reflects precision, material expertise, and the ability to handle complex requirements.

Aerospace Components

CNC milled titanium and aluminum aerospace parts including brackets, housings, and lightweight structural elements.

Automotive Components

Engine blocks, gear housings, and custom prototypes milled from aluminum and steel alloys.

Hydraulic & Water Engineering Parts

Stainless steel and specialty alloy valves, fittings, and flow-control components produced through precision CNC milling services.

Electronics & High-Tech Parts

Heat sinks, housings, and precision connectors milled from aluminum and engineering plastics.

Industrial Equipment Parts

Large-scale brackets, gears, and structural parts milled from steel and alloy materials.

Research & Laboratory Prototypes

Small-batch prototypes and custom-designed experimental parts machined in various materials.

Why Choose Us for CNC Milling Services?

When choosing a CNC milling services provider, customers often want answers to practical questions: Can this supplier meet my precision requirements? Do they understand my industry’s unique needs? Will the parts be consistent and reliable? Below, we address the key factors that matter most to industries such as aerospace, automotive, and high-tech manufacturing.

Precision and Tolerances

Visitor Concern: Aerospace and medical customers often ask if we can meet strict dimensional accuracy and repeatability.

Our Solution: We work with advanced 3-axis and 5-axis CNC milling equipment capable of producing parts with tight tolerances, ensuring critical components—like aerospace brackets or medical housings—fit and function as intended.

Material Expertise

Visitor Concern: Automotive and electronics clients worry whether their chosen materials—like aluminum alloys, stainless steel, or engineering plastics—can be reliably machined.

Our Solution: We have experience with a wide range of materials, from aluminum 6061-T6 to stainless steel 316 and titanium. This ensures that whether it’s lightweight automotive prototypes or corrosion-resistant marine fittings, the material is milled correctly and efficiently.

Scalability and Consistency

Visitor Concern: Industrial equipment manufacturers and laboratories often ask if we can handle both prototypes and large production runs with consistent quality.

Our Solution: Our workflow is built for flexibility. We support small-batch prototyping for R&D as well as full-scale production for industries like automotive and industrial machinery, while maintaining stable quality across every part.

Surface Finish and Post-Processing

Visitor Concern: Electronics and aerospace industries care about smooth surface finishes, coatings, and cosmetic appearance in addition to functionality.

Our Solution: We provide multiple finishing options—such as polishing, anodizing, or coating—to meet functional and visual standards, ensuring CNC milled parts are both durable and aesthetically reliable.

Industry Understanding

Visitor Concern: Customers want a partner who understands the regulations, certifications, and performance requirements of their sector.

Our Solution: From aerospace to automotive, we are familiar with the standards and documentation processes required. This helps streamline project communication and ensures parts meet the specific compliance needs of each industry.

FAQs about CNC Milling

Contact Us / Request a Quote

Get Answers to Your CNC Milling Questions

Whether you need a prototype for research, a batch of automotive components, or aerospace parts requiring tight tolerances, our CNC milling services are designed to meet your needs.

What You Can Expect:

- Clear communication: Direct feedback on feasibility, lead time, and cost for CNC milling services.

- Industry knowledge: Understanding of aerospace, automotive, electronics, and industrial equipment requirements.

- Flexible support: From one-off prototypes for laboratories to large production runs for manufacturers.

- Precision focus: Assurance of tolerances and finishes that match your application.

What to Include in Your RFQ Form:

- Part drawings or 3D models (STEP, IGES, PDF,DWG,TIFF,STL…)

- Material requirements (e.g., aluminum 6061-T6, stainless steel 316, titanium)

- Expected tolerances and surface finish (if applicable)

- Quantity (prototype or production)

- Application notes (aerospace, automotive, research, etc.)