Introduction: Why Your Prototype Supplier Matters More Than You Think

A prototype is not “just a sample.”

It is the first physical proof that your design works — or doesn’t.

For engineers, a failed prototype means redesign cycles and lost time. For procurement teams, it means emergency rework, unexpected costs, and uncomfortable conversations with management. In industries such as automotive, industrial equipment, aerospace, and medical devices, a single tolerance issue can delay an entire program.

This is why choosing the right cnc machining prototype service is a strategic decision, not a tactical one.

Many buyers — especially overseas customers — struggle with the same problems:

- Parts arrive late or out of tolerance

- Surface finish doesn’t match the drawing

- Material grade is unclear or undocumented

- Communication breaks down once the PO is placed

Whether you are validating a new automotive bracket, testing a gearbox housing, or preparing a functional assembly for investor review, you need more than a machine shop. You need a prototype cnc machining service that understands engineering intent, manufacturing reality, and quality risk.

This guide combines engineering best practices with real-world procurement experience to help you:

- Understand what defines a professional CNC machining prototype service

- Compare prototype services vs. production machining

- Specify tolerances, materials, and finishes correctly

- Reduce cost, lead time, and rework risk

- Choose between local options (Georgia / Savannah) and qualified global manufacturers

What Is a CNC Machining Prototype Service?

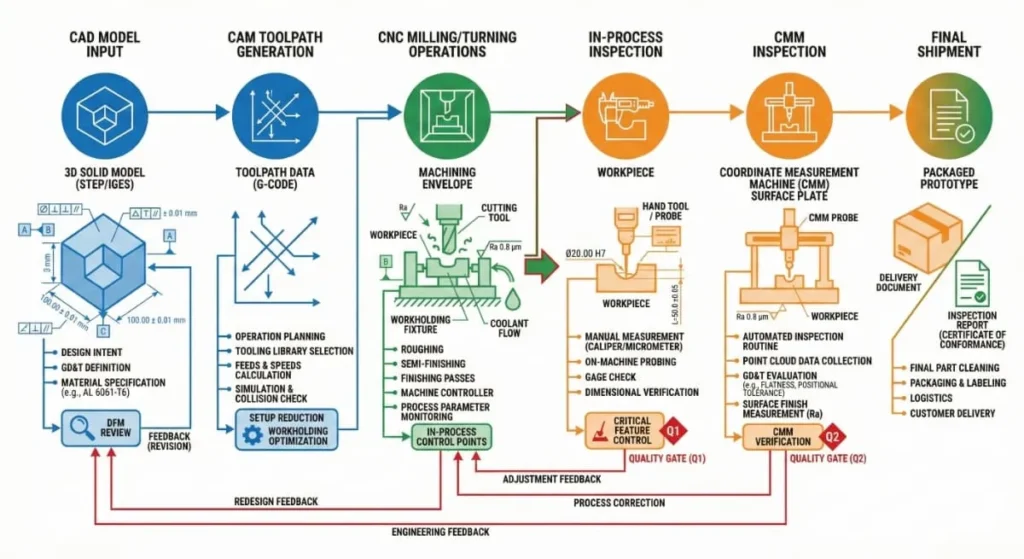

A cnc machining prototype service specializes in producing one-off or low-volume parts directly from CAD models and engineering drawings using subtractive manufacturing processes such as CNC milling, turning, and multi-axis machining.

Unlike production machining, prototype machining prioritizes:

- Speed over cycle-time optimization

- Flexibility over dedicated tooling

- Engineering feedback over blind execution

Professional prototype cnc machining services typically include:

- Fast quoting and DFM (Design for Manufacturability) review

- Machining of metals and engineering plastics

- Optional surface finishing and heat treatment

- Inspection reports (CMM, FAI, dimensional reports)

The goal is simple: validate design intent quickly and accurately, before you commit to tooling or volume production.

Prototype Machining vs. Production Machining: Know the Difference

One of the most common mistakes buyers make is treating prototype machining like production machining — or worse, expecting production pricing and tolerances from a prototype shop.

When a CNC Machining Prototype Service Is the Right Choice

Choose prototype cnc machining services when:

- You need 1–100 parts for fit, function, or assembly testing

- Design iterations are expected

- Time-to-market is more critical than unit price

- You need engineering input before cutting metal

Prototype shops excel at handling change. A good prototype partner will question your drawing, flag risk areas, and suggest alternatives.

When to Transition to Production Machining

Production machining becomes the better choice when:

- Geometry and tolerances are frozen

- Volume justifies dedicated fixtures and process optimization

- Cost per part and repeatability are priorities

A capable cnc machining prototype service manufacturer should help you bridge this transition, not force you to start over with a new supplier.

What Defines a Professional CNC Machining Prototype Service?

Not all prototype shops are equal. From an engineering and procurement standpoint, a reliable cnc machining prototype service should demonstrate strength in four core areas.

1. Engineering-Led DFM Feedback

A professional service does not simply “machine to print.”

Before machining begins, engineers should review:

- Wall thickness and aspect ratios

- Internal corners vs. tool radius limitations

- Hole depth-to-diameter ratios

- Datum structure and GD&T intent

Actionable DFM feedback — ideally within 24 hours — can reduce cost and lead time dramatically without compromising function.

2. Process Capability and Machine Range

To handle non-standard parts efficiently, prototype cnc machining services must offer multiple processes in-house.

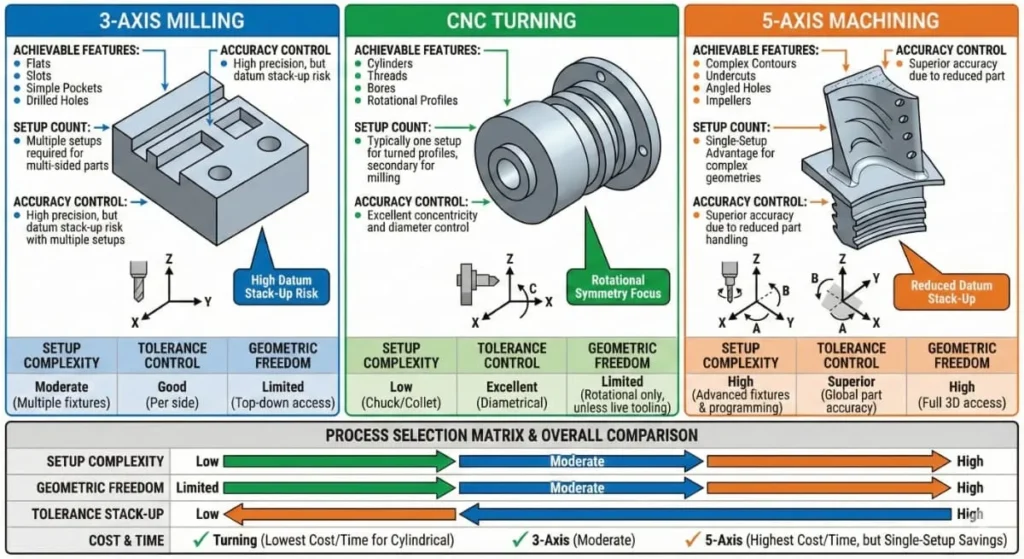

CNC Milling (3-Axis / 4-Axis)

Best for prismatic parts such as brackets, housings, and plates.

- Typical prototype tolerances: ±0.13 mm (±0.005 in)

- Tighter tolerances achievable on critical features with proper setup

CNC Turning

Ideal for cylindrical components like shafts, spacers, and bushings.

- Excellent concentricity and roundness

- Live tooling enables secondary features in one setup

5-Axis CNC Machining

Used for complex geometries requiring multi-angle access.

- Reduces multiple setups

- Minimizes datum stack-up

- Particularly valuable for aerospace and high-end automotive prototypes

A cnc machining prototype service manufacturer that lacks process diversity will either outsource — or limit what it can do reliably.

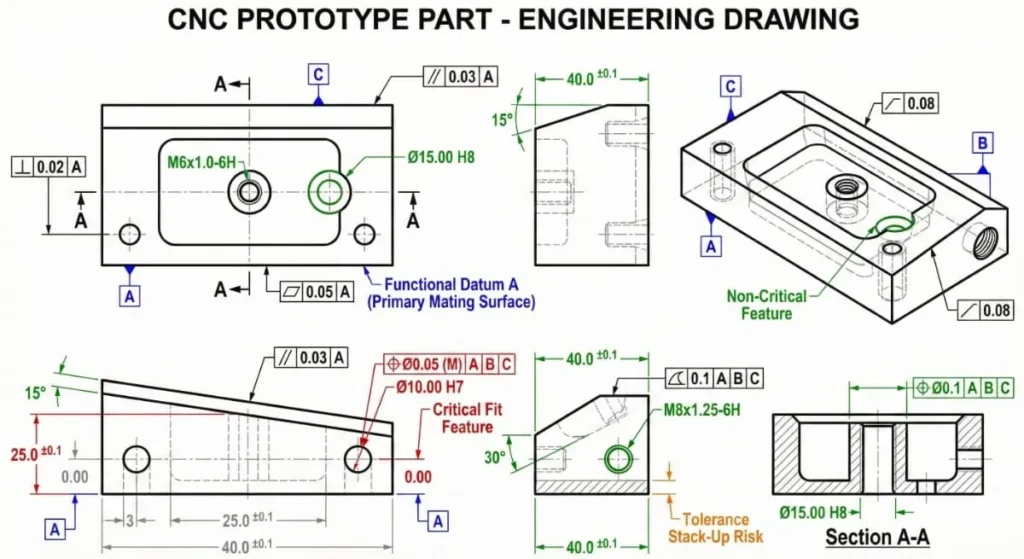

Tolerances, Standards, and Drawings: What You Must Specify

From a procurement and quality perspective, unclear drawings are the #1 cause of prototype failure.

Referencing the Right Standards

- ISO 2768-1: General tolerances for non-critical dimensions

- ASME Y14.5: GD&T standard for functional control

- ISO 9001: Quality management system reference

Using these standards correctly allows prototype cnc machining services to interpret your intent consistently.

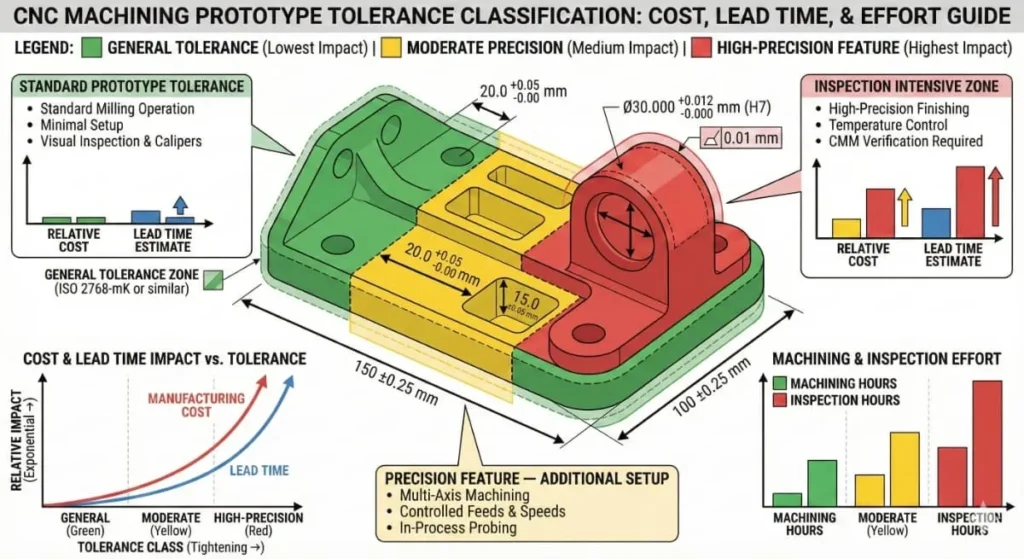

Practical Tolerance Guidelines for Prototypes

- General features: ±0.13 mm (±0.005 in)

- Precision features: ±0.05 mm (±0.002 in) or tighter by agreement

- Avoid over-tolerancing non-functional dimensions

Remember: tighter tolerances increase cost and machining time disproportionately.

Material Selection for CNC Machining Prototypes

Material choice affects not only performance, but also machinability, cost, and lead time.

Common Metals Used in Prototype CNC Machining

- Aluminum 6061-T6: Excellent machinability, ideal for functional prototypes

- Aluminum 7075-T6: Higher strength, closer to steel behavior

- Stainless Steel 304 / 316: Corrosion resistance for harsh environments

- Alloy Steel: Strength-critical automotive and industrial parts

- Titanium (Grade 2 / 5): High strength-to-weight, aerospace and motorsport

A professional cnc machining prototype service should provide material certificates (MTR/COA) on request.

Engineering Plastics for Prototypes

- POM / Delrin: Low friction, dimensional stability

- Nylon (PA): Tough and economical

- PEEK: High temperature and chemical resistance

Surface Finishing: Function and Appearance

Surface finish is often underestimated in prototype stages.

Common options offered by prototype cnc machining services include:

- As-machined (functional, visible tool marks)

- Bead blasting (uniform matte appearance)

- Anodizing (aluminum corrosion resistance and color)

- Passivation (stainless steel corrosion resistance)

- Powder coating (durable industrial finish)

Always specify Ra values where surface finish affects sealing, friction, or aesthetics.

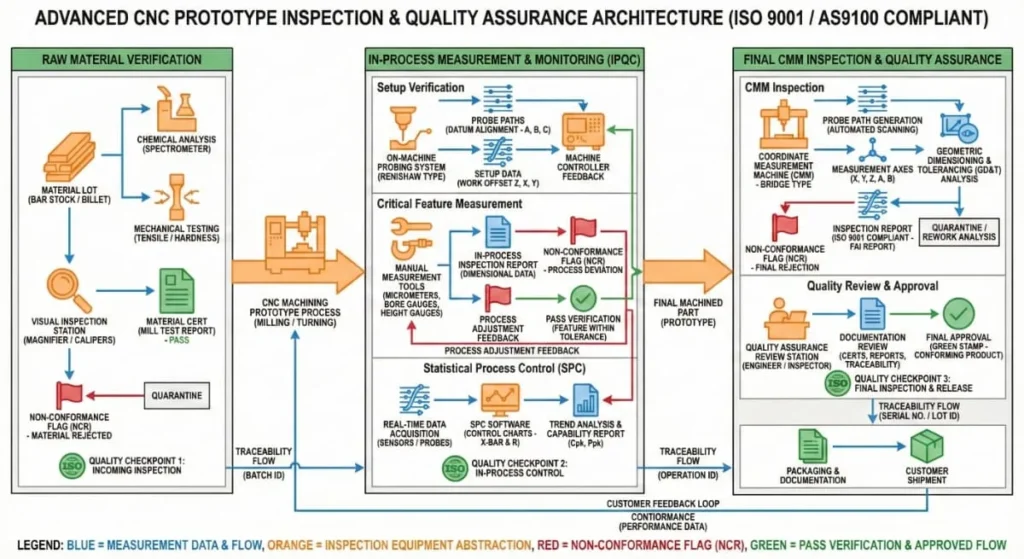

Inspection and Quality Assurance: What to Ask For

Quality assurance is where many low-cost prototype suppliers fall short.

A credible cnc machining prototype service manufacturer should be able to provide:

- CMM inspection reports for critical dimensions

- First Article Inspection (FAI) upon request

- Calibration records for inspection equipment

- Material traceability documentation

If a supplier cannot explain how they verify tolerances, treat it as a red flag.

Local vs. Global CNC Machining Prototype Services

Many buyers search specifically for:

- cnc machining prototype service georgia

- cnc machining prototype service savannah

Local shops offer advantages such as easier visits and shorter domestic shipping. However, capacity constraints and lead times are common, especially for complex parts.

Why Many Buyers Choose Global Prototype Manufacturers

Qualified overseas cnc machining prototype service manufacturers often provide:

- Greater capacity and faster turnaround

- Competitive pricing for complex, low-volume parts

- Experience supporting international OEMs

With proper communication, documentation, and inspection, global sourcing can be as reliable as local — and often more scalable.

Lead Times, Cost Drivers, and How to Reduce Both

Typical Prototype Lead Times

- Simple aluminum parts: 3–5 business days

- Complex geometries or special finishes: 7–12 days

Key Cost Drivers

- Number of setups

- Tight tolerances

- Material hardness

- Surface finishing and inspection requirements

How to Speed Up Your Prototype

- Simplify geometry where possible

- Limit tight tolerances to critical features

- Provide complete drawings with GD&T

- Respond quickly to DFM questions

Step-by-Step: How to Order from a CNC Machining Prototype Service

- Prepare files: STEP + 2D PDF drawing

- Submit RFQ: Include quantity, material, finish, inspection needs

- Review DFM feedback

- Approve quote and lead time

- Production and inspection

- Shipping with documentation

A smooth process reflects a mature prototype cnc machining service.

Frequently Asked Questions

Q: What is the minimum order quantity?

A: Most professional cnc machining prototype services support MOQ = 1.

Q: Can prototype services handle tight tolerances?

A: Yes, on selected features — provided they are clearly specified and inspected.

Q: Should I choose a local shop or overseas supplier?

A: It depends on complexity, urgency, and capacity. Both can work with the right controls.

Conclusion: Choose a Prototype Partner, Not Just a Supplier

A cnc machining prototype service is not just cutting metal — it is helping you make decisions faster and with less risk.

The right partner understands engineering intent, respects tolerances, documents quality, and communicates clearly. Whether you work with a local cnc machining prototype service in Georgia or Savannah, or with experienced global manufacturers, the principles remain the same.

Validate early. Document clearly. Inspect intelligently.

If you do that, your prototypes will accelerate development — not slow it down.

Ready to Move Forward?

Upload your drawings for a free DFM review and a detailed quote including lead time, tolerance strategy, and inspection options.

No minimum order quantity.

Engineering feedback included.