CNC Machining Materials We Work With

From lightweight aluminum to advanced titanium alloys, we provide the right material for your prototyping and production needs.

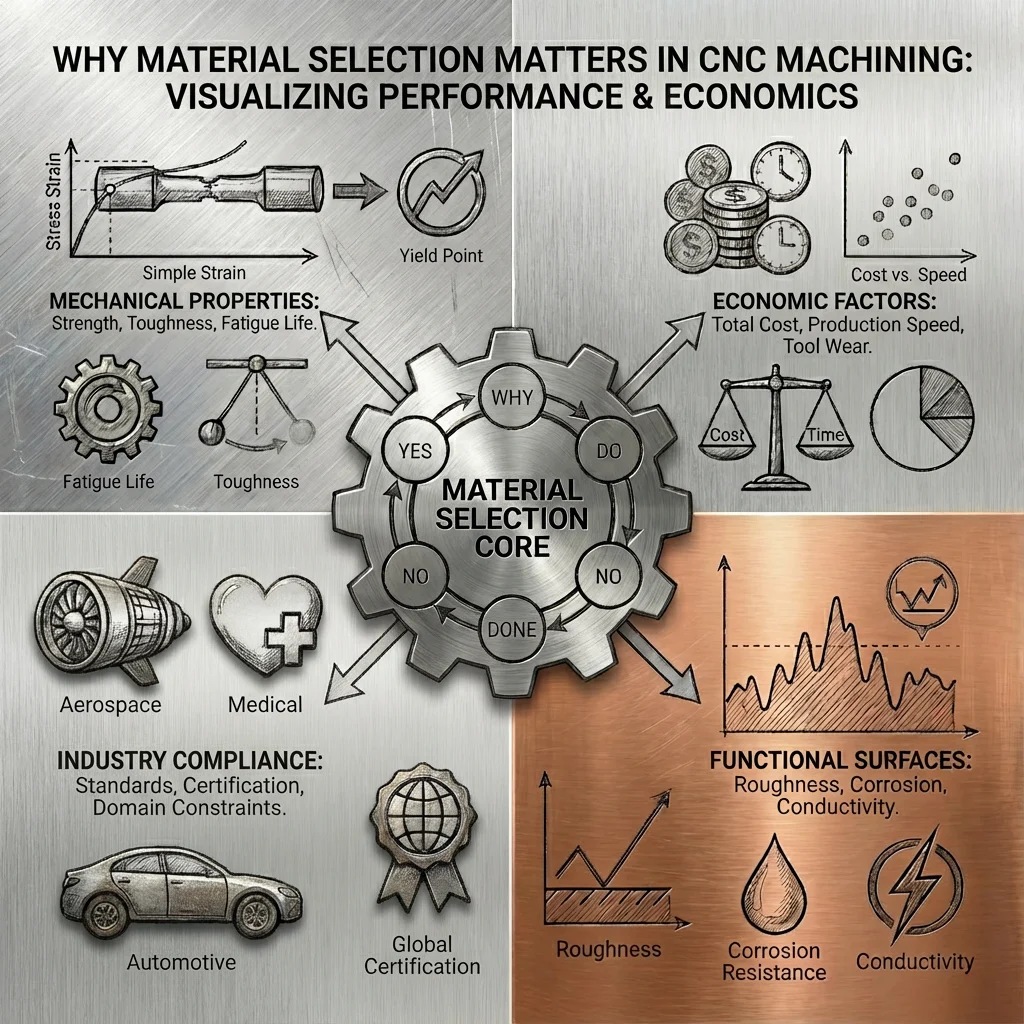

Why CNC Machining Materials Selection Matters

The choice of cnc machining materials directly impacts the performance, durability, and cost-effectiveness of CNC machined parts. Selecting the right cnc machining materials ensures your parts meet functional requirements, withstand demanding conditions, and align with your industry standards.

Performance & Strength

CNC machining materials define mechanical properties such as tensile strength, hardness, and weight. Choosing the right one ensures reliability in real-world applications.Cost & Efficiency

Different cnc machining materials come with different machining costs and production speeds. Proper selection helps balance performance with budget.Application-Specific Suitability

From aerospace turbine blades to medical implants, every industry has unique requirements. Material selection ensures compliance with safety and regulatory standards.Surface Finish & Appearance

Whether you need polished aesthetics, corrosion resistance, or electrical conductivity, materials influence the final finish and usability of your parts.

Common CNC machining materials

When it comes to CNC machining, the choice of material is of utmost importance each time. Every material has its own unique properties, such as strength, corrosion resistance, or lightweight performance. In industries like aerospace, automotive, energy, and medical equipment, selecting the right material is crucial for achieving the best results.

Aluminium Alloy

Why it’s important:

Aluminum is lightweight, corrosion-resistant, and highly machinable, making it one of the most widely used CNC machining materials. It combines excellent strength-to-weight ratio with good surface finishing and is ideal for both prototypes and end-use parts.

Common challenges:

Built-up edge: aluminum tends to stick to cutting tools.

Dimensional stability in thin walls: deflection can occur.

Heat generation: improper cooling can cause surface issues.

Surface finish uniformity: cosmetic parts require careful tooling paths.

Materials / Grades we machine:

6061-T6 — balanced strength, corrosion resistance (general parts, enclosures).

7075-T6 — high-strength aerospace alloy.

2024 — excellent fatigue resistance (aerospace, automotive).

5052 — great corrosion resistance (marine applications).

6082 — structural applications, European standard alloy.

Typical applications:

Aerospace brackets, automotive prototypes, consumer housings, electronic enclosures, machine components.

Typical tolerances achievable:

Standard: ±0.01 mm; thin-wall geometries require careful support to avoid warping.

How we solve common issues:

We use sharp carbide tools, optimized toolpaths, flood coolant, and high-speed machining to minimize burrs, improve surface finish, and control tolerances.

Stainless Steel

Why it’s important:

Stainless steels offer high strength, wear resistance, and excellent corrosion resistance, making them indispensable for medical, aerospace, and industrial components.

Common challenges:

Work hardening: improper feeds cause rapid tool wear.

Heat buildup: can cause distortion or poor finish.

Machining forces: stainless is tougher, needs rigid setups.

Surface passivation: sometimes requires post-processing

Typical applications:

Surgical instruments, food-grade components, aerospace fasteners, energy sector fittings.

Typical tolerances achievable:

±0.005 mm achievable with stable fixturing and proper tooling.

How we solve common issues:

We use coated carbide tools, proper cutting fluids, and rigid clamping. Optimized feeds/speeds minimize work hardening and extend tool life.

Materials / Grades we machine:

303 — good machinability (fittings, fasteners).

304 — excellent corrosion resistance (industrial equipment).

316 / 316L — marine, chemical, medical use.

17-4PH — precipitation-hardening, aerospace/defense.

410 — wear-resistant, used in tools, valves.

Carbon Steel & Alloy Steel

Why it’s important:

Carbon and alloy steels are backbone materials for heavy-duty mechanical components. They offer excellent strength, wear resistance and toughness, making them ideal for shafts, gears, housings and tooling where load-bearing and durability matter.

Common challenges:

Hardness & tool wear: Higher-carbon and alloy steels increase cutting forces and tool wear.

Heat generation & distortion: Milling/turning can create heat that leads to part distortion if not managed.

Post-process treatment: Many steel parts require heat treatment (hardening/tempering) which can change dimensions.

Surface finish for hardened parts: Achieving fine surface finish on hardened sections can be difficult without secondary operations.

Typical applications:

Shafts, gears, coupling sleeves, bearings housings, tooling components, dies, automotive drivetrain parts, heavy machinery components.

Typical tolerances achievable:

Standard: ±0.01 mm under normal machining conditions; with rigid fixturing, proper tooling and temperature control ±0.005 mm is achievable on many features. Note: tolerance after heat treatment depends on the specific process — we provide guidance and predictive allowances for post-HT distortion.

Grades we machine:

1018 / 1020 (mild carbon steels): Good machinability for general mechanical parts.

1045 (medium carbon): Higher strength for shafts and structural parts.

4140 (alloy steel): High strength and fatigue resistance—common in automotive and tooling.

4340 (alloy steel): Very tough and used in aerospace and heavy-duty applications.

D2, O1 (tool steels): Wear-resistant steels for dies, molds, and cutting tools (usually require specialized tooling and processes).

How we solve common issues:

Use of coated carbide / CBN tooling, climb milling strategies and optimized feeds/speeds to reduce tool wear.

Through-coolant tools, controlled cutting parameters and interrupted cuts to manage heat.

Rigid fixturing and vibration damping to improve surface finish and dimensional stability.

Pre-machining allowances and cooperation with heat-treat vendors; we can deliver pre- and post-heat-treatment workflows (including stress relief, grinding or finish passes).

When required, we provide secondary operations (grinding, surface hardening, finishing) and advise on design tolerances to accommodate post-process changes.

Titanium

Why it’s important:

Titanium combines exceptional strength-to-weight ratio with corrosion resistance and biocompatibility. It is widely used in aerospace, medical implants, and high-performance automotive parts.

Typical applications:

Aerospace turbine blades, medical implants, racing components, subsea equipment.

Typical tolerances achievable:

±0.01 mm; fine features require adaptive toolpathing.

How we solve common issues:

We apply high-pressure coolant, rigid carbide tools, and adaptive machining strategies to control heat, reduce wear, and ensure stability in precision machining.

Common Challenges:

Low thermal conductivity: heat concentrates at the tool edge.

Springback effect: causes tool chatter and dimensional issues.

Tool wear: high cutting forces demand advanced tooling.

Fixturing: lightweight yet rigid setups needed.

Materials / Grades we machine:

Grade 2 (Commercially Pure) — good corrosion resistance.

Grade 5 (Ti-6Al-4V) — aerospace & medical standard alloy.

Grade 9 (Ti-3Al-2.5V) — tubing and aerospace structural.

Brass & Copper

Why it’s important:

Brass and copper offer excellent electrical and thermal conductivity, corrosion resistance, and machinability. They are critical in electrical, plumbing, and decorative components.

Typical applications:

Electrical connectors, heat exchangers, fluid fittings, decorative prototypes.

Typical tolerances achievable:

±0.01 mm achievable with careful fixturing and optimized toolpathing.

How we solve common issues:

We use sharp tooling, low-friction tool coatings, and deburring processes to maintain clean edges and cosmetic quality. For copper, we apply flood coolant to control heat.

Common challenges:

Burr formation: soft metals tend to form burrs.

Surface scratching: cosmetic applications demand careful handling.

Material cost: copper is expensive, requiring precision to avoid waste.

Thermal expansion: can affect precision machining.

Materials / Grades we machine:

Brass C360 — highly machinable, fittings, valves.

Brass C260 (Cartridge Brass) — springs, fasteners.

Copper C110 — excellent conductivity for electrical parts.

Beryllium Copper — aerospace, connectors, high-load springs.

Plastics

Why it’s important:

Engineering plastics are lightweight, corrosion-resistant, cost-effective, and often used for functional prototypes, insulators, and low-load mechanical parts. Plastics allow fast iteration in prototyping while offering material properties (electrical insulation, low friction) that metals can’t always provide.

Typical applications:

Bushings, insulators, gear prototypes, consumer housings, fluid-handling fittings, medical trays/prototypes.

Typical tolerances achievable:

Standard: ±0.02 mm; with controlled tooling, fixturing and environment ±0.01 mm is achievable for many plastics features (depends on geometry & material).

How we solve common issues:

We use sharp, high-helix carbide tooling, optimized feeds/speeds, effective chip evacuation (air/vacuum), temperature control and proper fixturing to minimize deformation and burrs — ensuring prototypes meet both functional and aesthetic requirements.

Common challenges:

Thermal sensitivity: some plastics deform or melt if cutting heat is not controlled.

Dimensional stability: viscoelastic behavior can cause slight dimensional shifts (warping).

Chip control & burrs: soft materials can form long strings or burrs if tooling/feeds are wrong.

Surface finish consistency: achieving both functional tolerances and cosmetic finish can be tricky.

Materials / Grades we machine:

POM (Delrin) — low friction, good wear resistance (bushings, gears).

ABS — prototyping housings and cosmetic parts.

Nylon (PA6 / PA66) — good toughness, bearings, structural small parts.

PEEK — high-performance, heat-resistant, used in medical and aerospace prototypes.

PTFE (Teflon) — low friction, chemical resistance, seals and insulators.

Polycarbonate (PC) — strong, impact-resistant housings.

CNC machining Materials Comparison Table

Choosing the right cnc machining materials is critical for balancing strength, machinability, cost, and application-specific performance. To help you compare, we’ve prepared a side-by-side table of common cnc machining materials we machine at CNMP. This allows engineers and buyers to quickly evaluate options before requesting a quote.

Suggested Table Structure

| Material Category | Common Grades | Key Properties | Machinability | Cost Level | Typical Applications |

|---|---|---|---|---|---|

| Aluminum Alloys | 6061,6081, 7075, 2024 | Lightweight, corrosion-resistant, good strength | ★★★★★ | $$ | Aerospace, Automotive, Construction |

| Stainless Steel | 304, 316, 17-4 PH | Corrosion-resistant, durable, hygienic | ★★★★ | $$$ | Medical, Food Processing, Chemical Equipment |

| Carbon & Alloy Steel | 1045, 4140, 4340 | High strength, heat treatable | ★★★★ | $$-$$$$ | Automotive, Engineering Machinery, Shipbuilding |

| Titanium | Ti-6Al-4V | High strength-to-weight, corrosion-resistant, biocompatible | ★★ | $$$$$ | Aerospace, Medical Implants |

| Inconel & Superalloys | Inconel 718, Hastelloy | Excellent heat & corrosion resistance | ★★ | $$$$$ | Turbines, jet engines |

| Brass & Copper Alloys | C380, C110 | High conductivity, easy machinability | ★★★★★ | $$$ | Electronics, fittings |

| Plastics | ABS, POM, Nylon, PEEK | Lightweight, versatile, chemical-resistant | ★★★★★ | $-$$$ | Prototyping, medical dev. |

Industries We Serve with These Materials

Selecting the right material is not just a technical decision—it directly impacts performance, cost, and long-term reliability in different industries. Each sector, from aerospace to medical, places unique demands on cnc machining materials such as aluminum, titanium, stainless steel, engineering plastics, and advanced alloys. Below, we outline how these materials are applied in typical industries and the challenges they help solve.

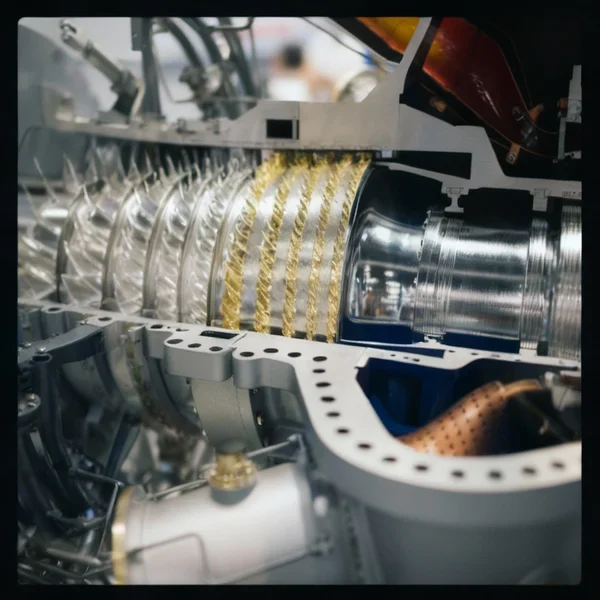

Aerospace

Key Needs: Lightweight yet strong materials for structural and engine components.

Material Applications:

- Aluminum & Titanium Alloys: Used in turbine blades, housings, and airframe parts for strength-to-weight ratio.

- Stainless Steel: Applied in high-heat and corrosion-prone environments.

Automotive

Key Needs: Cost efficiency, durability, and performance for high-volume production.

Material Applications:

Carbon Steel & Alloy Steel: Ideal for shafts, gears, and drivetrain components.

Aluminum: Used in lightweight structural parts and engine prototypes.

Engineering Plastics: Applied in housings, interior parts, and prototypes for fuel efficiency.

Medical

Key Needs: Biocompatibility, corrosion resistance, and precision.

Material Applications:

Titanium & Stainless Steel (316L): Used for implants, surgical tools, and dental components.

Medical-Grade Plastics (PEEK, PTFE): Preferred for lightweight, non-reactive devices and housings.

Energy

Key Needs: High strength, corrosion resistance, and heat tolerance.

Material Applications:

Superalloys & Stainless Steel: Used for turbomachinery, oil & gas equipment, and renewable energy components.

Engineering Plastics: For fluid handling components and electrical insulation.

Research & Development / Labs

Key Needs: Flexibility in prototyping, wide range of material testing, complex geometries.

Material Applications:

Aluminum & Plastics: Rapid prototyping for structural and experimental parts.

Advanced Alloys: Used for stress-testing and specialized R&D projects.

FAQs about CNC Machining Materials

Clear answers to common questions about selecting and working with materials for CNC machining.

Start Your Project with the Right CNC Machining Materials

Selecting the right material is the foundation of a successful CNC machining project. Whether you need lightweight plastics, durable steels, or advanced alloys, our team is here to guide you. Share your requirements and get a tailored solution today.