Introduction: Why a Specialized cnc acrylic service Matters

Acrylic (PMMA) looks simple—until you try to machine it to tight tolerances and “glass-like” clarity. Many buyers receive parts that are cloudy, melted at edges, scratched in transit, warped after machining, or develop micro-cracks (crazing) weeks later. These failures usually come from one thing: treating PMMA like metal, or treating “clear plastic” like a commodity.

A professional cnc acrylic service is not just “CNC cutting.” It is a controlled manufacturing system that manages heat, internal stress, chip evacuation, workholding deformation, and post-processing—while providing the documentation and packaging a B2B buyer needs to approve parts quickly.

This guide combines two perspectives into one: (1) deep machining know-how (tools, failure modes, finishing) and (2) a practical procurement playbook (supplier vetting, QC documents, lead time, negotiation, and shipping). If you are evaluating a cnc acrylic service for prototypes or production, you can use this as both a technical reference and a sourcing checklist.

1) PMMA Basics: Cast vs. Extruded (Choose Before You Quote)

PMMA (polymethyl methacrylate) is valued for clarity (often cited around 92% visible light transmission), UV stability, and a premium appearance. But your results depend heavily on the grade you buy.

A good cnc acrylic service will ask which PMMA type you want—because machining behavior and polish quality differ.

Cast PMMA

- Better for polishing and optical work

- Generally lower risk of “gumming” and heat-related haze when cut correctly

- Often preferred for thicker blocks, lenses, light guides, and display-grade parts

Extruded PMMA

- Often cheaper and commonly available in consistent sheet thickness

- Higher internal stress can increase risk of melting, burrs, and stress cracking if parameters or finishing are wrong

- Fine for many non-optical housings and simple panels if expectations are clear

Procurement takeaway: If you need optical clarity after machining, specify cast PMMA explicitly in the RFQ to your cnc acrylic service. “Acrylic” alone is not a spec.

2) When CNC Is the Right Process (vs. Laser Cutting & Injection Molding)

A reliable cnc acrylic service should also tell you when not to use CNC.

Choose CNC machining when:

- You need 3D geometry (pockets, manifolds, precision bores, threads, sealing features)

- Tolerances and datums matter for assembly

- You need controlled finishing (optical faces, polished internal channels, or edge standards)

- Volumes are prototype to medium batch (often 1–5,000 pcs, depending on geometry and cycle time)

Choose laser cutting when:

- Parts are 2D profiles from sheet

- Edge quality on thin sheet is the priority

- Turnaround speed is critical and tolerances are moderate

Choose injection molding when:

- Volumes are high enough to amortize tooling (often 5k–10k+ depending on part and market)

- Unit cost must be minimized at scale

- You accept tooling lead time and mold-flow / shrink control work

A strong cnc acrylic service can also propose hybrid workflows (CNC + laser + finishing) to reduce cost without sacrificing fit and clarity.

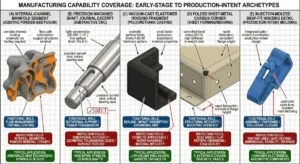

3) Capabilities Checklist: What a Real cnc acrylic service Should Have

Use this section as a supplier screening list. A supplier can “own machines” and still fail on PMMA if they lack plastic-specific discipline.

Minimum technical capabilities

- Dedicated plastic tooling (not “the same cutters used for aluminum yesterday”)

- Controlled workholding (soft jaws, vacuum fixtures, low-force clamping)

- Clear finishing options (polish/buff, vapor polishing, flame for edges where appropriate)

- Ability to machine both plates and cylindrical parts (milling + turning)

- 3-axis capability at minimum; 5-axis if you have complex surfaces that need continuity

Quality and documentation capability

- ISO 9001 quality management (baseline)

- First Article Inspection (FAI) reporting on request

- Material traceability and COA/COC options

- CMM or equivalent metrology for critical features

- Standardized visual inspection for scratches/haze (lighting and handling rules)

Communication and procurement readiness

- Fast DFM feedback (48–72 hours is common for serious suppliers)

- Quoting that separates machining, finishing, inspection, and packaging (to avoid “hidden costs”)

- Process photos or inspection photos at key gates

If a cnc acrylic service cannot show examples of QC reports and packaging for clear parts, expect risk.

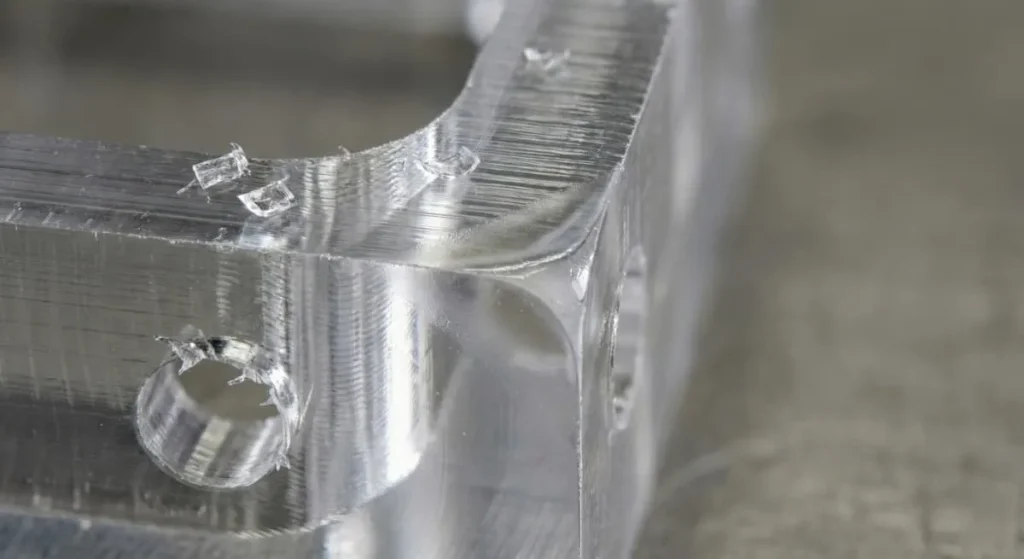

4) Machining Acrylic the Right Way: Milling, Turning, 3-Axis, 5-Axis

PMMA machining is heat-sensitive because plastics do not conduct heat like metals. The chip must carry heat away; otherwise you get melting, smearing, haze, and dimensional instability. A specialized cnc acrylic service builds its process around that reality.

CNC milling (3-axis and 5-axis)

- 3-axis is ideal for plates, panels, pockets, and general housings

- 5-axis is valuable when surface continuity matters (optical contours, complex manifolds, or when you want to minimize hand polishing by keeping tool contact consistent)

Tooling best practices commonly used by a high-end cnc acrylic service:

- High rake angle tools with polished flutes designed for plastics

- Very sharp edges (tool wear shows quickly as haze and tearing)

- Clean chip evacuation (air blast and appropriate coolant strategy)

CNC turning (lathes) for PMMA

Turning is effective for knobs, light pipes, cylindrical lenses, and round features, but chip control is critical. Long, stringy chips can wrap and scratch the surface.

A competent cnc acrylic service typically manages this via:

- Chip-breaking strategies and conservative depth-of-cut choices

- Proper coolant or air to clear the cutting zone

- In some cases, live tooling to finish cross-holes/flats in one setup (improves concentricity and reduces handling damage)

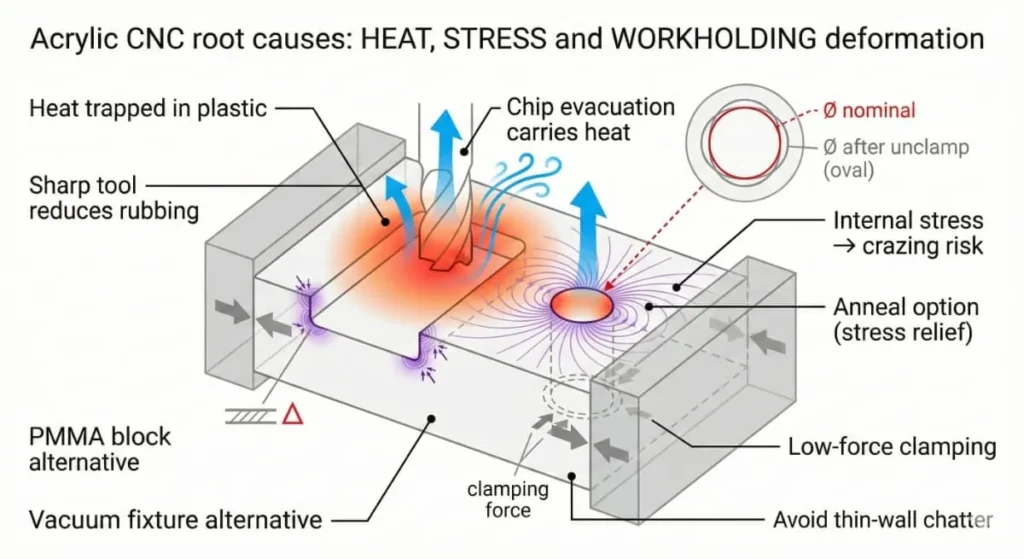

5) The Three Root Causes of Bad PMMA Parts: Heat, Stress, Workholding

Most failures map to one of these. Your cnc acrylic service should be able to explain which one they’re controlling—and how.

(1) Heat management

Symptoms:

- Melted edges, smeared surfaces, cloudy finish, burr buildup, dimensional drift

Controls:

- Sharp tools and correct feeds/speeds for plastics

- Removing heat through chips (not into the part)

- Air blast and/or plastic-compatible coolant strategy

- Avoiding “rubbing” passes that polish by melting (looks good briefly, fails later)

(2) Internal stress and crazing

Symptoms:

- Micro-cracks, especially after exposure to solvents (alcohol cleaners, adhesives, or aggressive environments)

- Warping after machining or after polishing

Controls:

- Proper stock selection (cast vs extruded)

- Stress-relieving (annealing) when the application is sensitive

- Process sequencing: roughing, rest, finishing; minimizing heat spikes

- Avoiding incompatible solvent exposure during cleaning/finishing

A mature cnc acrylic service will recommend annealing for critical optical parts, bonded assemblies, or tight flatness requirements.

(3) Workholding deformation

Symptoms:

- Holes go oval after unclamping

- Flatness changes after removing parts from vises

- Scratch marks from clamps or fixtures

Controls:

- Soft jaws matched to geometry

- Vacuum fixtures for plates

- Low-force clamping and support strategies

- Handling rules: protective film, clean benches, separation trays

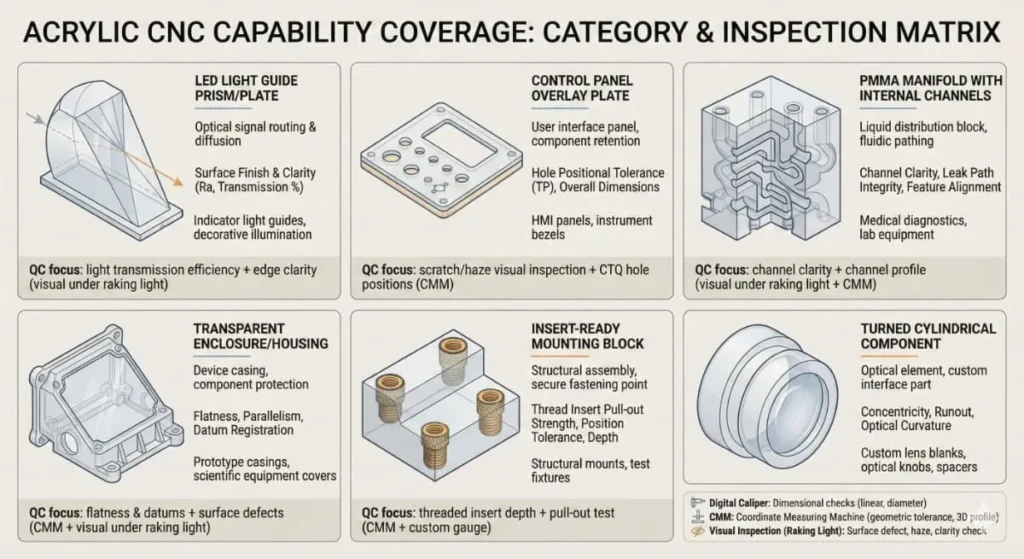

6) Optical Clarity & Surface Finish: Four Options (and When to Use Them)

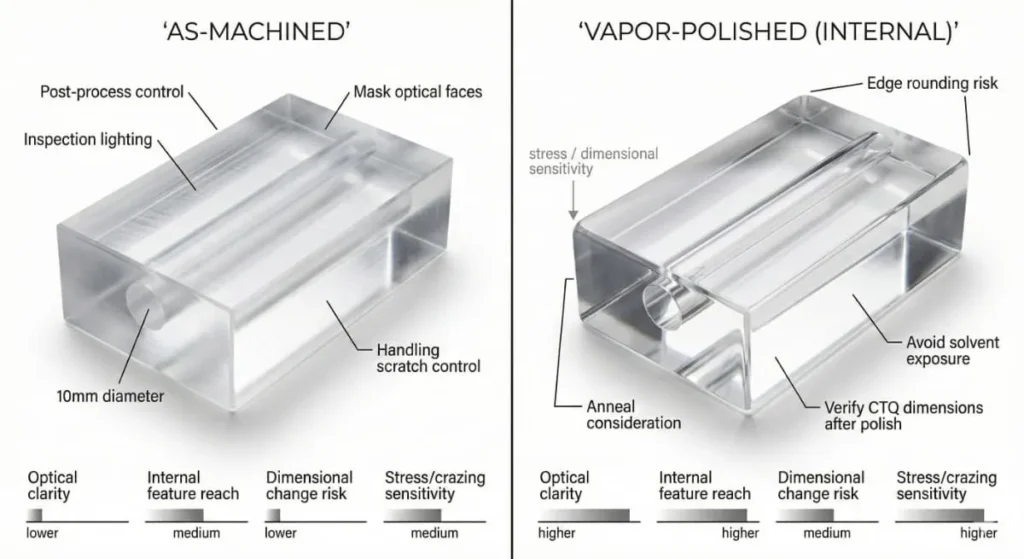

“As-machined PMMA” is usually translucent due to tool marks. If you need true transparency, finishing must be specified and controlled. A capable cnc acrylic service will offer multiple finishing routes and guide you on tradeoffs.

1) Mechanical polishing / buffing

- Best for accessible external faces

- High cosmetic quality possible

- Labor-intensive; hard to reach internal channels

2) Vapor polishing (chemical vapor)

- Can achieve very clear surfaces rapidly, including internal features and threads

- Requires strong process control; can introduce stress if not managed

- Not always suitable when sharp edges and tight dimensional control are critical (clarify acceptance criteria)

3) Flame polishing (primarily edges)

- Fast for simple edges on display parts

- Can round edges and add stress; less suitable for precision sealing edges

- Use with restraint; specify where it’s allowed

4) Diamond turning / optical machining

- Highest-end method for near-optical surfaces directly off-machine

- Suitable for lens-like surfaces and demanding optical applications

- More expensive; requires specialized equipment and know-how

Procurement tip: Ask your cnc acrylic service to propose a finishing plan per surface (Face A optical polish, Face B matte, edges flame-polish allowed/not allowed). “Polish all” increases cost and may cause unnecessary risk.

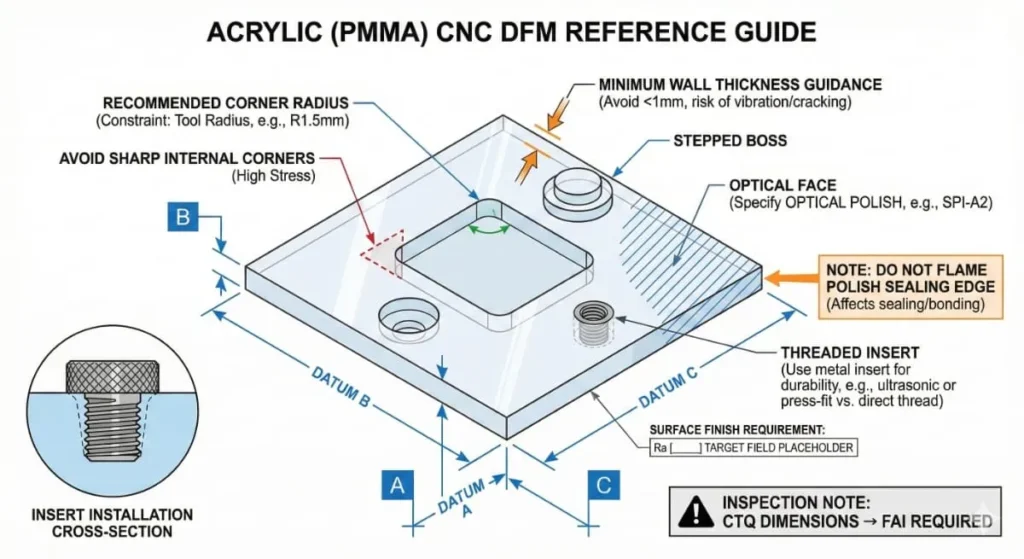

7) DFM Rules for Acrylic Parts (Reduce Cost, Improve Quality)

Sending a “perfect CAD” is not the same as sending a manufacturable acrylic design. Use this checklist before you contact a cnc acrylic service.

Geometry and strength

- Add internal corner radii (end mills are round; sharp corners drive tiny tools and cost)

- Avoid ultra-thin walls; thin walls chatter and crack more easily

- Keep deep narrow slots realistic; they trap chips and heat

Optical and cosmetic planning

- Identify optical faces on the drawing

- Avoid placing cosmetic faces against fixtures if you can redesign

- Consider sacrificial tabs/allowances for post-polish where needed

Threads and inserts

- For frequent assembly/disassembly, use metal threaded inserts rather than cutting threads directly into PMMA

- Define insert type and installation method (heat staking, ultrasonic, or press-fit per design)

A good cnc acrylic service should return DFM feedback that saves money (tooling choice, radii suggestions, datum strategy) rather than simply quoting what you sent.

8) Tolerances, GD&T, and How to Call Out Optical Surfaces

PMMA tolerances depend on geometry, size, thermal conditions, and finishing method. Over-specifying tolerances is one of the fastest ways to inflate cost.

Practical tolerance guidance (typical ranges)

- General features: often around ±0.1 mm depending on size and geometry

- Mating features / critical holes: often ±0.02 to ±0.05 mm with proper fixturing and inspection

- Flatness/parallelism: achievable, but sensitive to stress and clamping; call out only where needed

Reference standards (where applicable):

- General tolerance frameworks often reference standards like ISO 2768 (confirm with your supplier which standard they use for defaults)

How to specify optical requirements

Instead of “polished,” specify:

- Which face(s) require optical clarity

- Surface finish target (with context: Ra is useful, but optical clarity also depends on waviness and defects)

- Visual acceptance criteria (scratch class, haze allowance, inspection lighting method)

A professional cnc acrylic service will align finishing and inspection method to your functional need (light transmission, viewing clarity, or cosmetic appearance).

9) Quality Control & Documentation: What to Ask For (and Why)

For B2B sourcing, QC is where good suppliers differentiate. A trustworthy cnc acrylic service can produce parts and the evidence you need to approve them.

Core documents to request

- FAI report (first article inspection) with measured critical dimensions

- Material COA/COC (batch identification, grade confirmation)

- Inspection report for each lot (sampling plan or 100% inspection for critical features)

- Metrology evidence: CMM screenshots, optical comparator traces, or gauge records as appropriate

Inspections that matter for PMMA

- Dimensional inspection under stable conditions (temperature awareness matters for plastics)

- Visual inspection for scratches, bubbles, inclusions, haze, and edge defects

- Surface finish verification where required

- For light guides: optical checks (transmission/appearance) if that’s the function

If a cnc acrylic service cannot explain how they prevent scratches between machining, finishing, inspection, and packing, treat that as a red flag.

10) Packaging, Labeling, and Export Logistics (Prevent the “Scratch Surprise”)

Clear parts fail in shipping more often than in machining. Packaging is not an afterthought; it is part of the cnc acrylic service you are buying.

Packaging best practices for clear PMMA

- Protective film on optical faces before handling and inspection where possible

- Individual separation: tissue/foam dividers to prevent part-to-part rubbing

- Correct carton strength or wooden crate for long-distance shipments

- Orientation labels and “do not stack” rules when warpage risk exists

- Desiccant for long sea freight and humid routes (as needed)

Ask for packaging sample photos before shipment for high-value parts. A serious cnc acrylic service will already have a standard for this.

11) Pricing, Quoting, and Lead Times (What Actually Drives Cost)

Pricing for PMMA machining is driven by cycle time, setups, finishing labor, inspection level, and scrap risk. A transparent cnc acrylic service will break these out.

Main cost drivers

- 3-axis vs 5-axis complexity and setup count

- Material selection (cast PMMA usually costs more than extruded)

- Finishing method (buffing vs vapor vs diamond turning)

- Tight tolerances and inspection requirements (FAI, CMM time, documentation)

- Cosmetic requirements (scratch-free standards increase handling time)

Typical lead times (guideline ranges)

- Prototype / sample: often ~3–10 business days depending on finishing and workload

- Small batch (50–200 pcs): often ~1–3 weeks

- Larger batches: often ~3–8 weeks depending on capacity and finishing bottlenecks

Confirm material availability early. For many suppliers, polishing capacity—not machining—is the bottleneck in a cnc acrylic service project.

12) Automotive / High-Compliance Buyers: What to Add to Your Requirements

If you source for automotive or similarly strict industries, the baseline ISO 9001 approach may not be enough. Even if your supplier is not certified to IATF 16949, you can still request automotive-style controls from a cnc acrylic service.

Consider adding:

- Lot traceability (material batch + production lot ID on labels)

- Change control (no process/material/tool changes without written approval)

- Control of special characteristics (identify CTQ dimensions and inspection frequency)

- Retained samples and record retention time

- Packaging validation (transport vibration/abrasion protection for clear parts)

If PPAP is required, discuss feasibility early (FAI, dimensional results, material certs, process flow, control plan). The right cnc acrylic service will tell you what they can support and what must be simplified.

13) Case Studies (What “Good” Looks Like)

Case A: LED light guide prototype (optical clarity + tight datums)

- Material: cast PMMA

- Requirements: optical faces clear; mating datums controlled; scratch-free packaging

- Solution from the cnc acrylic service: CNC milling with plastic-dedicated tooling, controlled workholding, defined optical polishing on specified faces, FAI with CMM on datums, protective film + separated packaging

- Result: assembly-ready parts with clear approval evidence (FAI + visual inspection standard)

Case B: Control panel overlay parts (speed + cost balance)

- Material: extruded PMMA

- Requirements: 2D profiles, holes, clean edges, fast delivery

- Solution: hybrid workflow (laser for profiles + CNC for precision features) and edge finishing only where necessary

- Result: faster turnaround and cost optimization while meeting functional requirements—exactly what a pragmatic cnc acrylic service should propose

Case C: Manifold with internal channels (clarity inside features)

- Material: cast PMMA

- Requirements: transparent internal channels; minimal haze; controlled stress risk

- Solution: machining strategy focused on heat control, then vapor polishing for internal features, plus stress-management plan (sequencing/optional anneal depending on risk)

- Result: clear channels where buffing tools cannot reach—an advantage of an advanced cnc acrylic service

14) Copy-Paste RFQ Template + Acceptance Criteria

Use this template to reduce back-and-forth and get comparable quotes from multiple vendors. Send it to any cnc acrylic service you are evaluating.

RFQ Subject: RFQ – PMMA (Acrylic) CNC Machined Parts – [Project Name] – [Qty] – [Due Date]

1) Files attached:

- 3D: STEP/IGES

- 2D drawing PDF with datums, tolerances, surface notes

2) Material:

- PMMA (Acrylic) – [Cast / Extruded], [clear/color], thickness/block size

- Material certificate required: [COA/COC yes/no]

3) Quantity:

- Prototype: [1–5 pcs]

- Production: [xx pcs] with expected repeat orders: [yes/no]

4) Critical features (CTQ):

- List CTQ dimensions and tolerances

- Datum scheme: [A/B/C]

- Any fits: [press-fit/clearance fit] + target values

5) Finishing:

- Optical faces: [Face ID] require [optical polish / vapor polish / mechanical polish]

- Edges: [flame polish allowed/not allowed]

- Matte areas: [bead blast/sanding] if needed

- Protective film required on: [faces]

6) Inspection & documentation:

- FAI required: [yes/no]

- Inspection method: [CMM / comparator / gauges]

- Visual inspection standard: scratches/haze criteria + inspection lighting requirement if you have one

- Photos required: [setup + finished surfaces + packaging]

7) Packaging & shipping:

- Individual separation required: [foam/tissue]

- Export packaging: [carton/crate]

- Shipping term: [EXW/FOB/CIF]

- Destination: [city/country]

8) Quotation request:

- Itemized quote separating: machining, finishing, inspection/FAI, packaging, shipping

- Lead time: sample + production

- Payment terms: [requested]

Acceptance criteria (minimum):

- Meets drawing tolerances for all CTQ dimensions

- No visible haze/smear on optical faces under agreed inspection lighting

- No handling scratches beyond agreed standard

- Packaging prevents part-to-part contact during transit

A mature cnc acrylic service will respond with DFM notes, risks, and options—rather than just a price.

15) FAQ (People Also Ask)

Q1: What should I send to a cnc acrylic service for an accurate quote?

Send STEP/IGES + 2D drawings with tolerances, datums, material grade (cast/extruded), finishing notes (optical faces), quantity, and QC document requirements (FAI/COA).

Q2: Can a cnc acrylic service produce truly transparent parts straight off the machine?

Usually “as-machined” is not fully transparent. Optical clarity typically requires polishing (mechanical, vapor, or diamond turning depending on geometry and requirements).

Q3: How do I prevent crazing or stress cracks in parts from a cnc acrylic service?

Specify appropriate material (often cast PMMA for optical work), ensure heat is controlled during machining, avoid incompatible solvents, and consider stress-relieving/annealing for sensitive designs.

Q4: What tolerances can a cnc acrylic service realistically hold?

It depends on part size, geometry, and inspection method. Many jobs run general tolerances around ±0.1 mm, while critical features may be held tighter (often ±0.02–±0.05 mm) with the right fixturing and QC plan.

Q5: Vapor polishing vs mechanical polishing—what should I choose from a cnc acrylic service?

Mechanical polishing is great for external faces and controlled edges. Vapor polishing can make complex/internal features clear but requires process control and may affect stress/dimensions. Choose per surface and function.

Q6: What QC documents should I require from a cnc acrylic service for overseas sourcing?

At minimum: material certificate (COA/COC) and an FAI for the first run. For critical projects, request CMM evidence, surface/visual inspection photos, and defined packaging proof.

Conclusion: How to Choose the Right cnc acrylic service (Without Guesswork)

Acrylic parts succeed or fail on details: tool condition, heat control, stress management, workholding, finishing method selection, inspection evidence, and scratch-proof packaging. The best cnc acrylic service combines machining expertise with procurement-friendly execution—clear quoting, fast DFM, robust QC documents, and reliable logistics.Welcome to contact CNMP Team to get professional quote!