Why China Machining Services Matter for Global Buyers

China machining services have become the backbone of global manufacturing supply chains—but for overseas buyers, choosing the right CNC supplier in China is still challenging.

If you are an engineer, sourcing manager, or OEM buyer, you may have experienced issues such as:

- Parts not matching drawings or tolerances

- Inconsistent surface finishing

- Poor communication and long revision cycles

- Unclear quality control processes

- Suppliers that quote low prices but lack real machining capability

This guide is written to solve those problems.

In this article, you’ll learn how professional CNC machining services in China actually work, how to evaluate suppliers beyond price, and how to avoid common sourcing risks—so you can confidently select a long-term manufacturing partner, not just a one-time vendor.

Understanding China Machining Services in Today’s Global Market

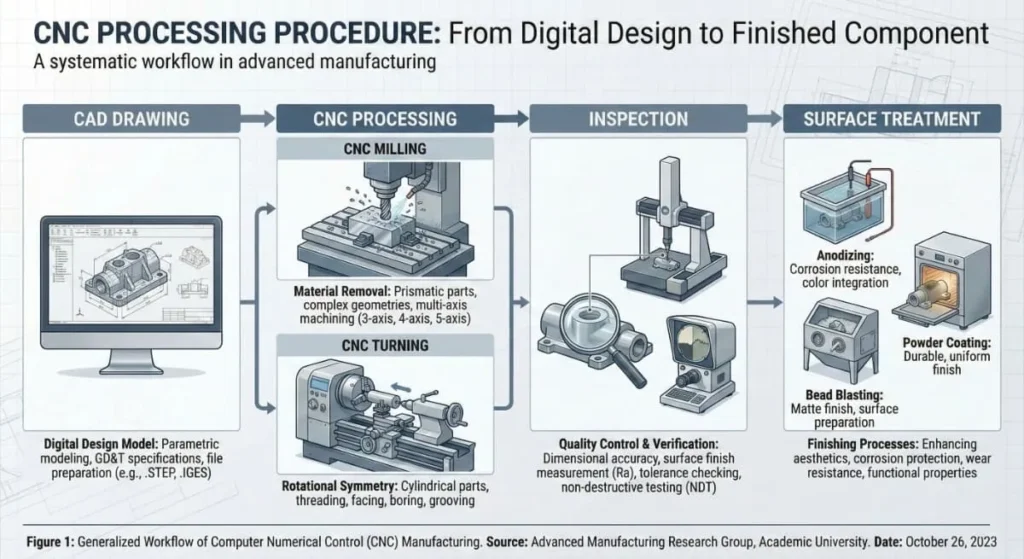

What Are China Machining Services?

China machining services refer to precision manufacturing solutions provided by Chinese factories, typically including:

- CNC milling

- CNC turning

- 4-axis and 5-axis CNC machining

- Surface finishing and post-processing

- Small-batch prototyping and volume production

Over the past 15 years, China has evolved from a low-cost manufacturing base into a high-precision CNC machining hub, serving aerospace, automotive, medical, robotics, and industrial automation industries worldwide.

Why Global Buyers Choose CNC Machining Services China

There are several reasons overseas buyers rely on CNC machining services China offers:

- Advanced equipment: Modern 3-axis, 4-axis, and 5-axis CNC machines

- Engineering talent: Experienced machinists familiar with GD&T and ISO standards

- Scalability: Smooth transition from prototype to mass production

- Cost efficiency: Competitive pricing without sacrificing precision

- Material availability: Aluminum, stainless steel, brass, plastics, titanium, and more

However, not all suppliers are equal—and that’s where due diligence matters.

Types of CNC Machining Services in China (Explained Simply)

CNC Milling Services

CNC milling uses rotating cutting tools to remove material from a solid block (workpiece).

Best for:

- Complex geometries

- Flat surfaces, slots, pockets

- Housings, brackets, plates

Typical tolerances: ±0.01 mm to ±0.005 mm

CNC Turning Services

CNC turning rotates the workpiece while cutting tools shape it.

Best for:

- Cylindrical parts

- Shafts, pins, bushings

- High concentricity requirements

This is why many buyers search for china cnc machining service and cnc turning parts manufacturers when sourcing precision round components.

5-Axis CNC Machining Service

5-axis CNC machining allows cutting from five directions in a single setup.

Advantages:

- Higher precision

- Fewer setups = fewer errors

- Ideal for complex aerospace or medical parts

Best for:

- Tight tolerances

- Complex angles

- Reduced lead time

Surface Finishing Services

Machining alone is not enough. Surface finishing directly affects function, corrosion resistance, and appearance.

Common finishes offered by china machining services include:

- Anodizing (Type II / Type III)

- Powder coating

- Bead blasting

- Polishing

- Black oxide

- Electroplating

A professional supplier controls both machining and finishing in-house or through qualified partners.

How to Evaluate China CNC Machining Service Suppliers (Step-by-Step)

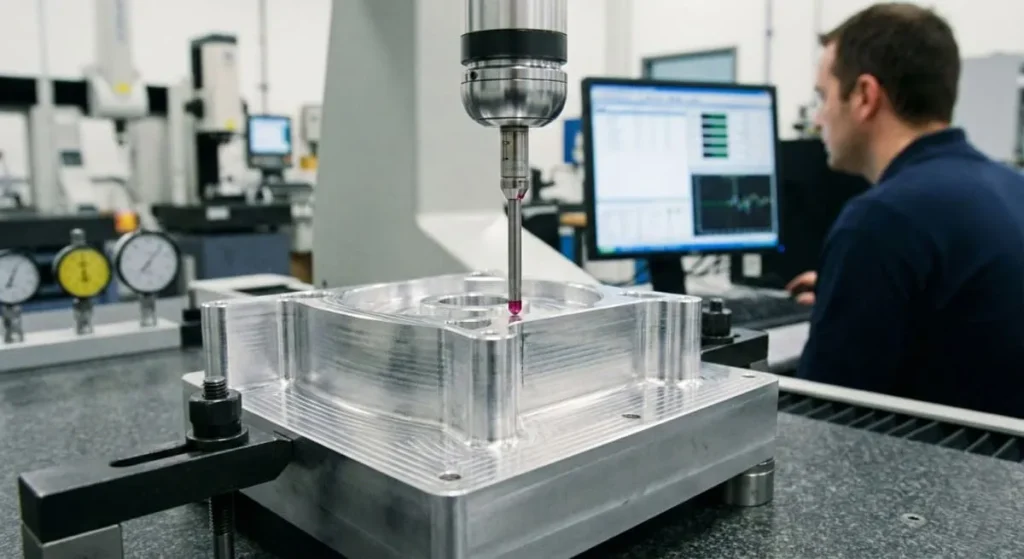

Step 1: Verify Real Manufacturing Capability

Many “suppliers” are actually trading companies.

Ask for:

- Factory photos/videos

- Equipment list (brands & models)

- In-house QC inspection tools

A real factory will confidently show:

- CNC machines on the shop floor

- CMM, height gauges, micrometers

- Organized production workflow

Step 2: Review Quality Management Systems (ISO)

Serious china machining services providers operate under formal standards such as:

- ISO 9001 – Quality Management

- ISO 13485 – Medical devices (if applicable)

- IATF 16949 – Automotive

According to ISO.org, certified quality systems reduce non-conformity rates and improve traceability across manufacturing processes.

External Reference:

ISO Official Website – Quality Management Standards

Step 3: Engineering Communication Matters More Than Price

A reliable CNC machining supplier should:

- Ask questions about drawings

- Flag tolerance risks early

- Provide DFM (Design for Manufacturability) feedback

If a supplier never questions your drawing, that’s a red flag—not a benefit.

Step 4: Tolerance & Inspection Capability

Professional CNC machining services China suppliers should clearly define:

- General tolerance (e.g., ISO 2768)

- Critical tolerances

- Inspection reports (FAI, CMM reports)

Ask for sample inspection reports before placing orders.

CNC Milling vs CNC Turning: Which Do You Need?

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Best For | Complex shapes | Cylindrical parts |

| Movement | Tool rotates | Workpiece rotates |

| Common Parts | Brackets, housings | Shafts, bushings |

| Accuracy | Very high | Extremely high concentricity |

Many china cnc machining service cnc turning parts suppliers also offer milling—but not all milling shops are good at turning. Choose based on part geometry.

Materials Commonly Used in China Machining Services

Professional CNC machining services China factories regularly work with:

Metals

- Aluminum (6061, 7075)

- Stainless steel (304, 316, 17-4PH)

- Carbon steel

- Brass & copper

- Titanium

Plastics

- ABS

- POM (Delrin)

- Nylon

- PEEK

- PTFE

Material traceability and certifications (RoHS, REACH) are essential for overseas compliance.

Common Risks When Sourcing China Machining Services (And How to Avoid Them)

Risk 1: Quoting Without Engineering Review

Solution: Choose suppliers that provide DFM feedback.

Risk 2: Inconsistent Surface Finish

Solution: Confirm finishing standards with samples or photos.

Risk 3: Communication Delays

Solution: Work with suppliers who assign dedicated project engineers.

Risk 4: No Final Inspection

Solution: Require inspection reports before shipment.

FAQ: China Machining Services (People Also Ask)

Are china machining services reliable for precision parts?

Yes—if you choose ISO-certified manufacturers with modern equipment and proper QC systems.

What tolerances can CNC machining services China achieve?

Typically ±0.01 mm for most parts, tighter for specific geometries with proper setup.

Is it safe to send drawings to China?

Work with suppliers that sign NDAs and have long-term export experience.

What industries use china cnc machining services?

Automotive, aerospace, medical, robotics, industrial automation, and electronics.

Why Work With a Professional China Machining Services Partner?

A reliable CNC machining partner offers more than low prices:

- Engineering-driven communication

- Stable quality across batches

- Scalable production capability

- Export experience & documentation

- Long-term manufacturing support

That’s the difference between a supplier and a manufacturing partner.

Conclusion: Choosing the Right China Machining Services Partner

China machining services can deliver world-class precision, efficiency, and value—but only when you work with the right factory.

Focus on:

- Engineering capability

- Quality systems

- Communication

- Proven export experience

If you do, CNC machining services China providers can become one of your strongest competitive advantages.

If you’re looking for reliable china machining services for custom non-standard parts, we invite you to:

👉 Upload your drawings for a free DFM & quotation review

👉 Contact us to discuss prototypes, tight tolerances, or OEM production

We don’t just machine parts—we help you manufacture with confidence.