Introduction: Why Sourcing Cast Iron is a Unique Challenge

Sourcing reliable custom components is one of the most significant challenges in modern supply chain management, but it becomes exponentially harder when dealing with materials as temperamental as cast iron. Whether you are designing heavy machinery bases, automotive engine components, or hydraulic manifolds, the quality of your cast iron cnc machined parts directly dictates the longevity and performance of your final assembly.

Cast iron remains the dominant material for industrial machinery—despite the rise of aluminum and advanced alloys—because of its superior vibration damping and cost-effectiveness. However, procuring these parts from overseas manufacturers often comes with a distinct set of headaches. From porosity issues in the raw casting to dimensional inaccuracies caused by rapid tool wear, the path to a perfect part is fraught with obstacles.

If you’re an engineer or procurement manager, you’ve likely faced at least one of these issues:

- ❌ Inconsistent casting quality causing scrap during the machining phase.

- ❌ Poor tolerance control because the manufacturer didn’t account for internal stress relief.

- ❌ Communication gaps where the machine shop blames the foundry, and the foundry blames the machine shop.

In this comprehensive guide, we will break down everything you need to know about sourcing high-quality cast iron cnc machined parts. We will explore the critical differences between gray and ductile iron, the technical nuances of machining them to tight tolerances, and exactly how to vet a cast iron cnc casting machining parts company to ensure you receive components that match your drawings perfectly.

Part 1: The Material Landscape – Gray vs. Ductile Iron

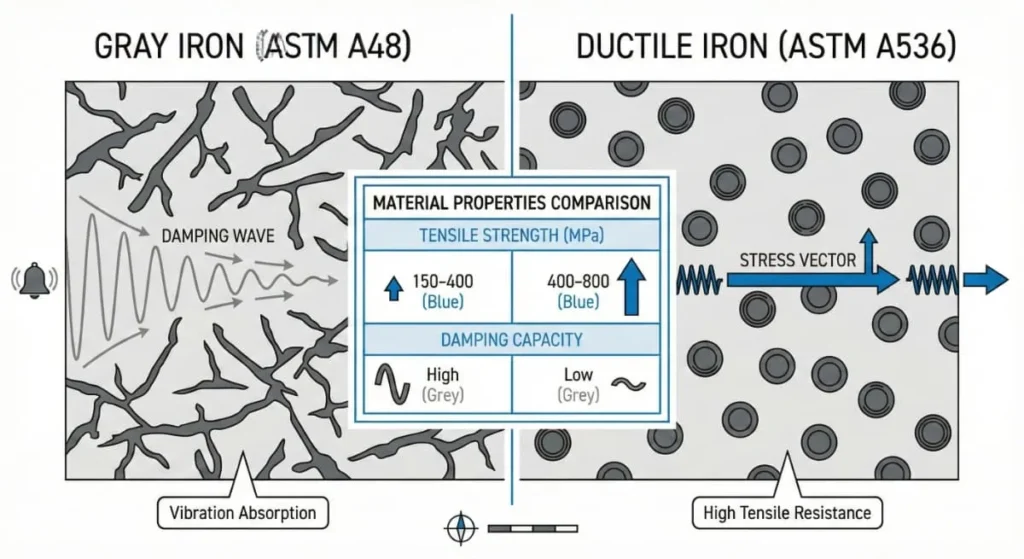

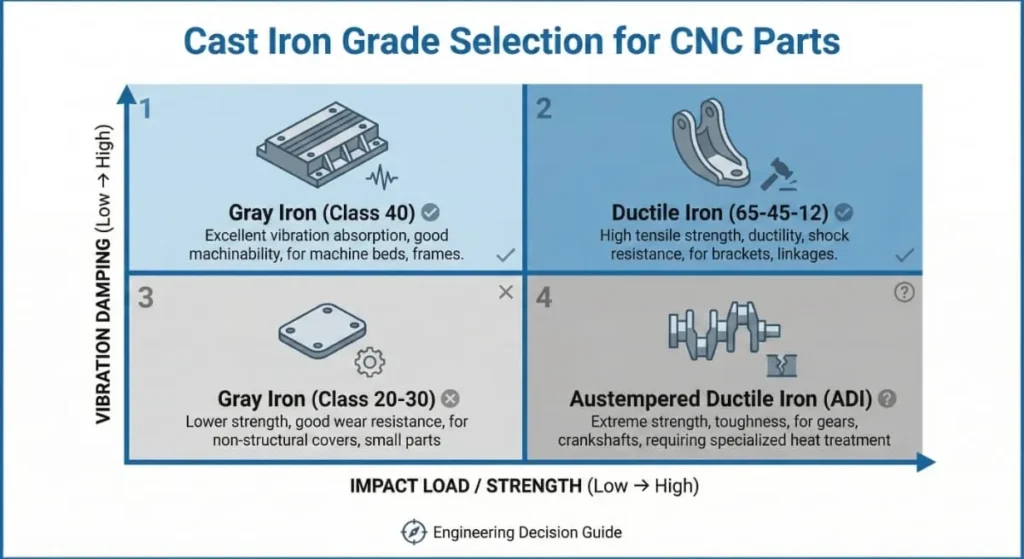

Before a cutter ever touches the metal, the success of your project depends on selecting the right grade of material. While many assume “iron is iron,” the distinction between the two main categories used in CNC machining—Gray Iron and Ductile Iron—is massive in terms of machinability and mechanical properties.

1. Gray Cast Iron CNC Machined Parts

Gray iron is the workhorse of the industrial world. It is characterized by its graphitic microstructure, which consists of flakes.

- The “Vibration Killer”: When we manufacture gray cast iron cnc machined parts, we are usually targeting applications that require superior vibration damping and high compressive strength. The graphite flakes act as internal cushions, absorbing vibrations 5 to 10 times better than steel.

- Machinability: Excellent. The graphite flakes act as a chip breaker and an internal lubricant, making it easier to cut than steel.

- Ideal Applications: Machine tool bases, pump housings, mounting brackets, and motor frames where stability is key.

- Common Grades: ASTM A48 Class 30, Class 40.

2. Ductile Cast Iron CNC Machined Parts (Nodular Iron)

Ductile iron (also known as Nodular Iron) treats the graphite with magnesium, causing it to form nodules or spheres rather than flakes. This small chemical change results in a material that is significantly stronger and more impact-resistant.

- The “Steel Substitute”: Ductile cast iron cnc machined parts are essential for components subject to tensile stress and shock loads. It offers a high strength-to-weight ratio and ductility—meaning it will bend before it breaks, unlike the brittle nature of gray iron.

- Machinability: Good, though it is slightly harder and tougher than gray iron, requiring more robust tooling strategies.

- Ideal Applications: Suspension parts, crankshafts, high-pressure valves, and hydraulic components.

- Common Grades: ASTM A536 65-45-12, 80-55-06.

Comparison Table: Gray vs. Ductile Iron for CNC Machining

| Feature | Gray Cast Iron | Ductile Cast Iron |

| Microstructure | Graphite Flakes | Graphite Nodules/Spheres |

| Primary Benefit | Vibration Damping | Tensile Strength & Toughness |

| Machinability | Excellent (Self-lubricating) | Good (Requires stronger tooling) |

| Impact Resistance | Low (Brittle) | High (Ductile) |

| Cost | Lower | Moderate |

| Best Use Case | Machine Bases, Pump Bodies | Hydraulic Valves, Auto Brackets |

Pro Tip for Buyers: Always specify the exact ASTM or ISO grade in your RFQ. Merely saying “Cast Iron” can lead to a manufacturer using a cheaper, lower-grade material that fails under load.

Part 2: The Integrated Manufacturing Workflow

One of the most confusing aspects of procurement is the relationship between the foundry (casting) and the machine shop (CNC). To get high-quality cast iron cnc casting machining parts, you need a seamless workflow between these two stages.

Step 1: The Raw Casting (Net Shape)

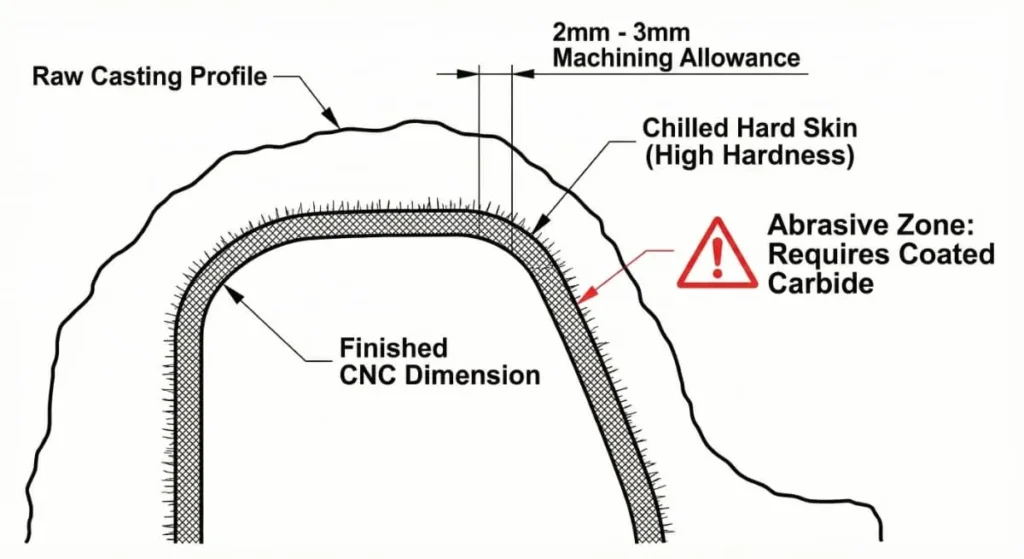

The process begins with sand casting or investment casting to create the “net shape” of the part. This raw casting will have rough surfaces and loose tolerances (usually +/- 1mm to 3mm). At this stage, it is critical to ensure the foundry has included sufficient “machining allowance”—usually 2mm to 3mm—to ensure the CNC process can clean up the surface entirely.

Step 2: Stress Relief (The Hidden Step)

Cast iron naturally contains internal stresses after solidification. If you skip this step, the part will warp after machining. Professional cast iron cnc casting machining parts companies apply annealing or normalizing heat treatments to relieve these stresses before the part ever hits the CNC machine.

Step 3: Precision CNC Machining

This is where we add value. We take the rough casting and use CNC milling and turning to machine the critical features: bearing bores, mounting faces, and threaded holes. The goal is to remove just enough material to achieve the dimensional tolerance (often +/- 0.01mm) without removing the hard “skin” of the casting unevenly, which can cause warping.

For complex geometries, such as engine blocks or gearboxes, we utilize 5-Axis CNC Machining. This allows us to machine 5 sides of a part in a single setup. This significantly improves accuracy by eliminating the errors introduced when manually flipping a heavy cast iron part.

Part 3: Technical Challenges in Machining Cast Iron

Why do some machine shops refuse to work with cast iron? It comes down to two main factors: Dust and Tool Life. As a specialized manufacturer, we have optimized our facility to handle these specific challenges.

1. The Graphite Dust Hazard

Unlike steel or aluminum, which produce long, curly chips, cast iron produces chips that are short, brittle, and dusty. This graphite dust is conductive and abrasive.

- The Risk: If not managed, this dust gets into the CNC machine’s electronics and ball screws, destroying the equipment.

- Our Solution: We utilize specialized vacuum extraction systems and fully enclosed guarding. This ensures that your cast iron cnc machined parts are produced on machines that are maintained at peak accuracy, rather than machines clogged with abrasive grit.

2. Dealing with the “Hard Skin”

The outer “skin” of a cast iron part is often chilled and significantly harder than the internal material. It may also contain sand inclusions from the molding process.

- The Problem: Hitting a sand pocket can shatter a standard carbide end mill instantly.

- The Strategy: We utilize specialized coated carbide inserts (often CVD coated) designed specifically for cast iron. We also employ “conventional milling” strategies for the first pass to cut from the inside out, avoiding the abrasive skin where possible.

Part 4: Critical Quality Control for Iron Parts

When you order cast iron cnc machined parts from overseas, Quality Control (QC) is your primary concern. How do you ensure the metal isn’t porous? How do you know the dimensions are correct?

1. Material Verification & Spectroscopy

Before machining begins, we verify the material composition using spectroscopy to analyze Carbon, Silicon, and Manganese levels. We also perform microstructure analysis to confirm if the graphite is flake (Gray) or nodular (Ductile). This ensures you are getting the grade you paid for.

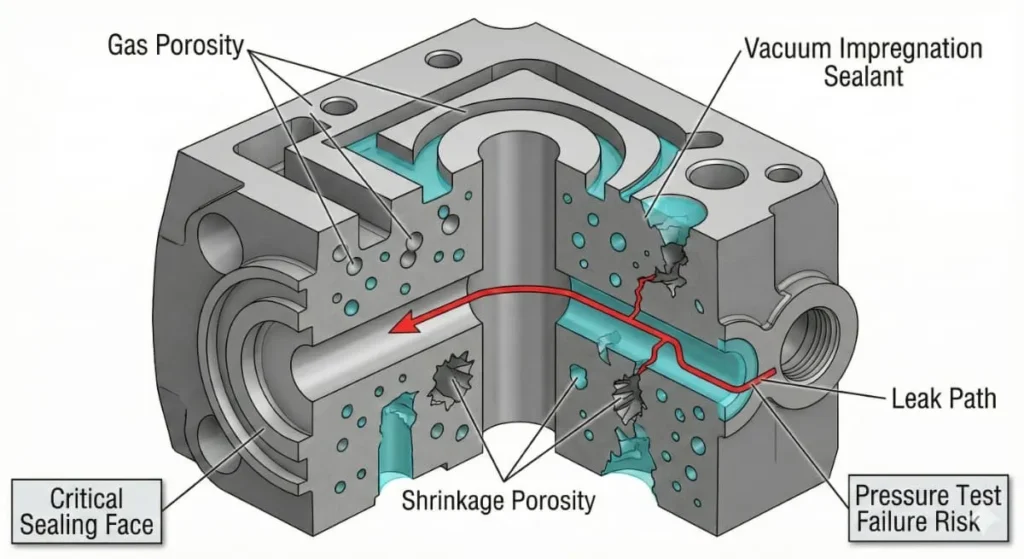

2. The War on Porosity

Porosity (air bubbles inside the metal) is the enemy of cast iron. It can lead to leaks in hydraulic parts or structural failure.

- Detection: We recommend pressure testing for hydraulic parts. During machining, if a void is uncovered on a critical sealing surface, the part is immediately flagged.

- Rescue: For ductile cast iron cnc machined parts used in high-pressure environments, vacuum impregnation can sometimes be used to seal microscopic pores.

3. Dimensional Accuracy (CMM Inspection)

Because cast iron releases internal stresses when the “skin” is removed, parts can move or warp.

- Roughing vs. Finishing: We perform a roughing pass, unclamp the part to let it “relax,” and then perform a finishing pass.

- Verification: Final dimensions are verified using a Coordinate Measuring Machine (CMM) to ensure adherence to GD&T (Geometric Dimensioning and Tolerancing) requirements.

Achievable Tolerances Table

| Feature Type | Standard CNC Tolerance | Notes |

| Linear dimensions | ±0.05 mm | Depends on part size |

| Precision bores | ±0.01 mm | Requires fine boring |

| Flatness | ≤0.03 mm | Critical for sealing faces |

| Position tolerance | ±0.02 mm | Verified by CMM |

Part 5: Design for Manufacturing (DFM) Tips

To get the best price and quality for your cast iron cnc machined parts, consider these design tips from our engineering team.

- Draft Angles: Remember that the raw part is cast. Ensure your design accommodates draft angles (taper) on non-machined surfaces to allow the pattern to be removed from the mold.

- Machining Allowance: Don’t leave too little material for us to remove. If the cut is too shallow, the tool rubs against the hard casting skin, wearing it out faster. We generally need 2mm-3mm of stock.

- Avoid Sharp Corners: In the casting design, use generous fillets. Sharp internal corners in castings are stress concentrators and are prone to cracking during the cooling phase.

Need a Design Check? Not sure if your draft angles are correct? Upload your drawings here for a free DFM review. We will analyze your CAD files to identify potential casting issues before production begins.

Part 6: How to Choose the Right Supplier

This is where many buyers make costly mistakes. To secure high-quality components, you must look beyond just the lowest price per unit.

1. Integrated Casting & Machining

Choose a cast iron cnc casting machining parts company that manages both the casting and the CNC machining. When one vendor is responsible for the final part, they cannot blame the foundry for “bad castings”—it is their responsibility to fix it. This reduces misalignment issues and machining scrap.

2. Surface Finishing Capabilities

Cast iron is highly susceptible to rust (oxidation). Leaving cast iron cnc machined parts bare is rarely an option unless they are constantly submerged in oil. Ensure your supplier offers:

- Anti-Rust Oil: For temporary protection during shipping.

- Black Oxide: For aesthetics and light corrosion resistance.

- Painting/Powder Coat: For external housings.

- Electroless Nickel Plating: For high corrosion environments.

3. E-A-T Compliance (Standards)

A professional supplier should comply with ISO 9001 (Quality Management), ISO 8062 (Casting Tolerances), and ASTM standards. These standards ensure traceability and audit readiness.

Frequently Asked Questions (FAQ)

Q1: What is the difference between cast iron and steel machining? Steel is generally ductile and produces long chips, whereas cast iron is brittle and produces short chips and dust. Machining cast iron cnc machined parts requires different cutting speeds and feeds, as well as specialized dust extraction, compared to steel.

Q2: Why is cast iron used for machine bases? Cast iron, specifically Gray Iron, has high internal damping capacity. It absorbs vibrations 5 to 10 times better than steel. This makes gray cast iron cnc machined parts ideal for machine tool bases, minimizing chatter and improving accuracy.

Q3: Can you hold tight tolerances on cast iron? Yes. With proper stress-relief cycles and high-quality CNC equipment, we can hold tolerances as tight as +/- 0.005mm on cast iron cnc machined parts. However, the quality of the raw casting plays a significant role in the final accuracy.

Q4: How do I prevent my cast iron parts from rusting during shipping? We apply a specialized heavy-duty VCI (Volatile Corrosion Inhibitor) oil or wrap the parts in VCI paper immediately after machining and cleaning. This protects the parts from saltwater corrosion during ocean freight.

Conclusion: Partner with a Specialist

Sourcing cast iron cnc machined parts doesn’t have to be a gamble. By understanding the material properties of gray and ductile iron, and partnering with a manufacturer who understands the intricacies of machining abrasive ferrous metals, you can secure high-quality components at competitive rates.

At our facility, we combine decades of metallurgical knowledge with state-of-the-art 5-axis CNC technology to deliver parts that meet your exact specifications. Whether you need a single prototype or a production run of thousands, we are the cast iron cnc casting machining parts company you can trust.

Ready to streamline your supply chain? Don’t let poor quality castings slow down your production line. 👉 Click here to upload your drawings for a free DFM review and Quote or contact our engineering team today to discuss your project requirements.