China Precision CNC Machining Services: A Complete Buyer’s Guide for Global Engineers and Procurement Managers

Introduction: Why Precision CNC Machining Services Matter More Than Ever

In today’s global manufacturing environment, precision cnc machining services are no longer optional — they are a fundamental requirement for companies producing complex, non-standard components.

Whether you are an engineer validating a new design, or a procurement manager responsible for sourcing reliable suppliers, the reality is the same:

one poorly machined part can delay an entire project, disrupt assembly lines, and damage your brand reputation.

Over the past decade, China has become a central hub for precision manufacturing. However, not all China machining services deliver true precision. Many buyers have experienced:

- Parts that look acceptable but fail tolerance inspection

- Inconsistent dimensions between batches

- Weak DFM feedback or slow engineering communication

- Overpromising machining capability without verification

This guide is written to solve those problems.

By combining engineering-driven manufacturing insight with real-world procurement experience, this article explains:

- What truly defines precision cnc machining services

- How China machining services have evolved to meet global standards

- How to evaluate real capability vs marketing claims

- Why many US buyers — including those searching for precision cnc machining services Georgia and precision cnc machining services Savannah — still choose China for complex parts

What Are Precision CNC Machining Services?

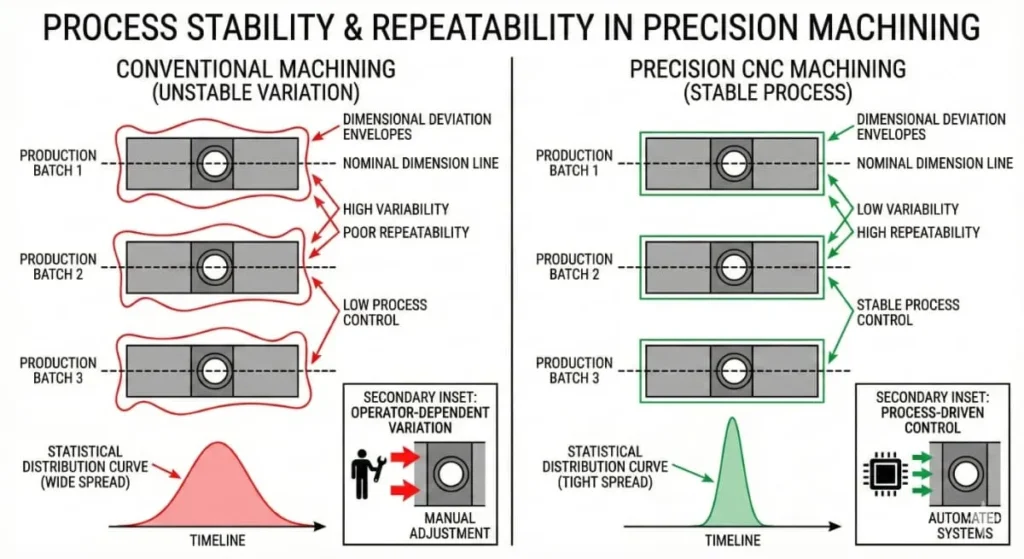

Precision cnc machining services refer to the production of metal or plastic components using computer-controlled machines capable of achieving tight tolerances, repeatable accuracy, and consistent surface quality across batches.

Unlike general CNC machining, precision machining focuses on:

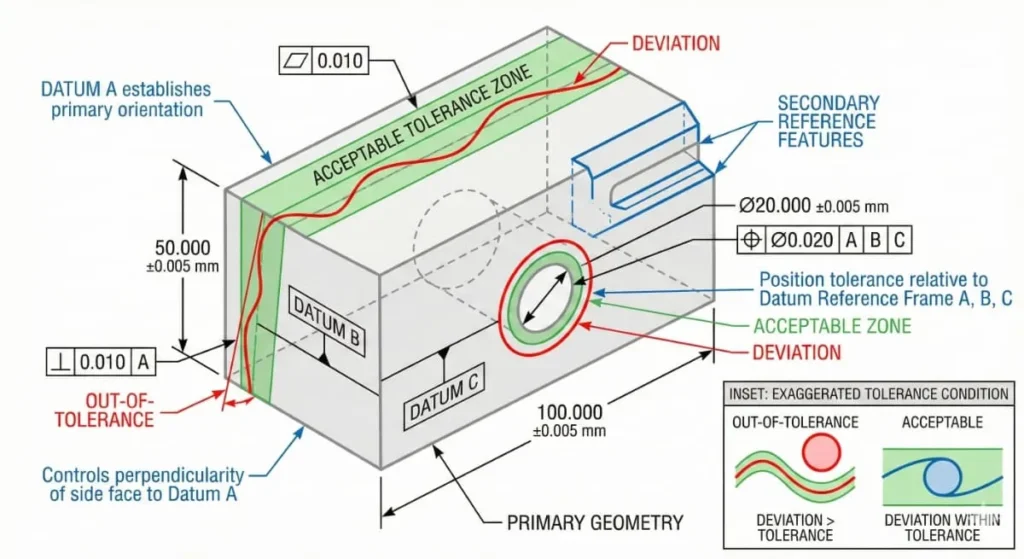

- Dimensional accuracy (commonly ±0.005 mm or tighter)

- Geometric tolerances (flatness, concentricity, perpendicularity)

- Surface integrity (Ra control, burr-free edges)

- Process repeatability from prototype to production

True cnc precision machining services are process-driven, not operator-dependent. Every step — programming, tooling, inspection, and documentation — is controlled.

Typical Precision CNC Machining Processes

- CNC milling (3-axis, 4-axis, 5-axis)

- CNC turning and mill-turn machining

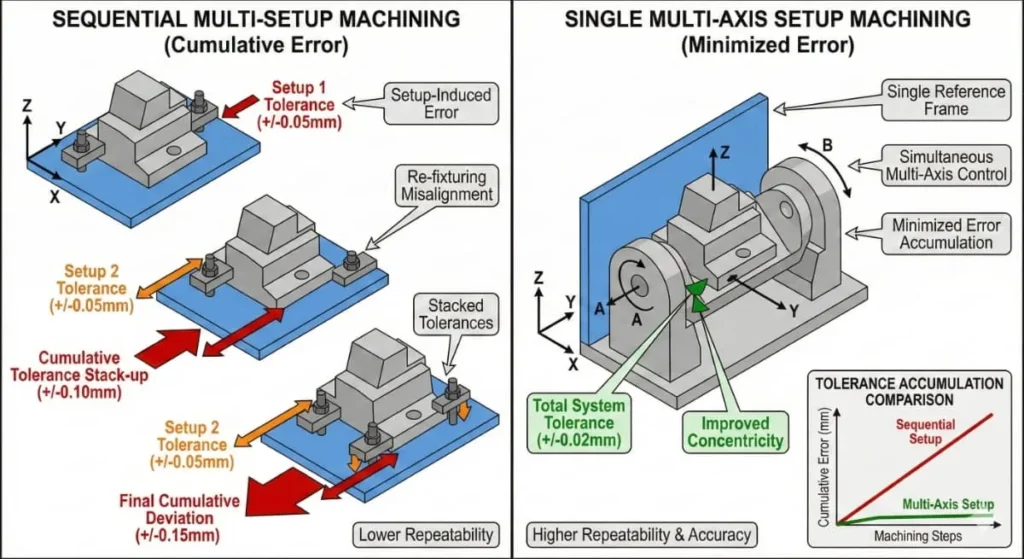

- Multi-axis simultaneous machining

- Secondary finishing and post-processing

- Full dimensional inspection and reporting

Industries that rely heavily on precision cnc machining services include:

- Automotive and EV components

- Aerospace structures and brackets

- Medical devices

- Robotics and automation

- Industrial equipment and tooling

Why China Leads Global Precision CNC Machining Services

The perception that China machining services are “low-cost but low-quality” is outdated.

Today, many Chinese manufacturers operate at the same technical level as suppliers in the US, Germany, or Japan — while maintaining a strong cost advantage.

1. Advanced CNC Infrastructure

Top-tier factories offering precision cnc machining services are equipped with:

- 5-axis CNC machining centers (Mazak, DMG MORI, Haas)

- Swiss-type CNC lathes for micro-precision parts

- Automated probing and tool monitoring systems

- Climate-controlled inspection rooms

This infrastructure allows complex geometries to be machined in fewer setups, improving accuracy and consistency.

2. Cost-Efficient Precision Manufacturing

For buyers comparing precision cnc machining services Georgia or Savannah-based suppliers with overseas options, cost is often a key factor.

China offers:

- Lower machining cost per hour

- Reduced tooling and fixture expenses

- Competitive pricing for low-volume, high-mix parts

- Better scalability for production runs

Many US companies use a hybrid sourcing strategy — prototyping locally and moving production to China once designs are validated.

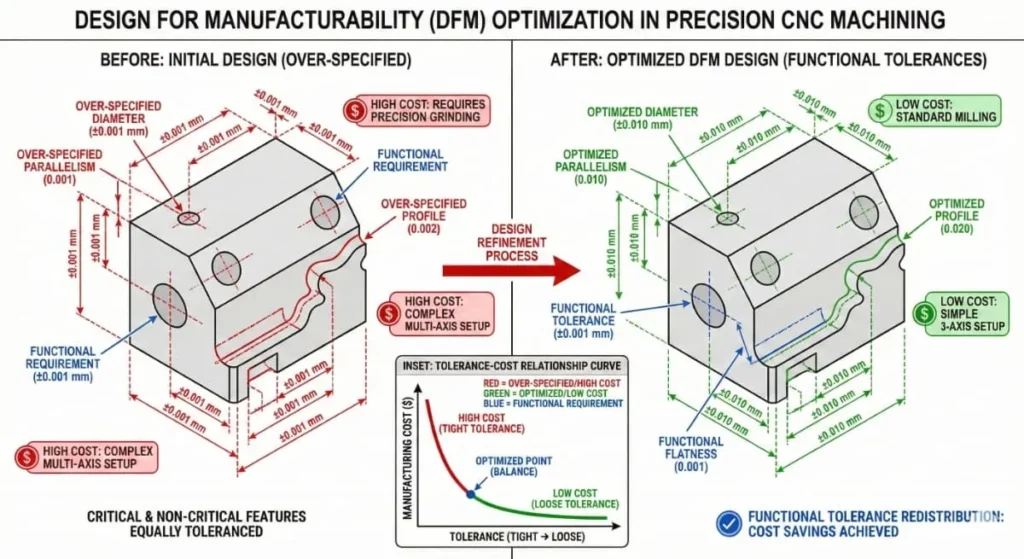

3. Engineering-Driven Manufacturing Culture

Leading China machining services now emphasize:

- Design for Manufacturability (DFM) feedback

- Tolerance optimization to reduce unnecessary cost

- Material substitution recommendations

- Process improvement suggestions

A reliable provider of cnc precision machining services should challenge unrealistic tolerances instead of blindly accepting them.

Precision CNC Machining vs Conventional Machining

| Aspect | Precision CNC Machining Services | Conventional Machining |

|---|---|---|

| Tolerance | ±0.005 mm or better | ±0.05 mm typical |

| Repeatability | Extremely high | Operator dependent |

| Geometry | Complex 3D shapes | Limited |

| Inspection | Full reports & CMM | Often minimal |

| Scalability | Excellent | Poor |

For global supply chains, predictability matters more than speed alone. Precision machining delivers stability.

Core Precision CNC Machining Services We Provide

CNC Milling Services (3-Axis to 5-Axis)

CNC milling is the backbone of precision manufacturing.

3-axis milling is ideal for cost-effective parts with simpler geometries.

4-axis milling allows indexed features and reduced setups.

5-axis precision cnc machining services enable complex contours, deep cavities, and undercuts in a single setup.

Applications include:

- Automotive brackets and housings

- Aerospace structural components

- Electronic enclosures

- Industrial fixtures

CNC Turning & Mill-Turn Machining

CNC turning is used for cylindrical components such as:

- Shafts

- Bushings

- Threaded fasteners

- Precision pins

Mill-turn machines combine turning and milling operations in one setup, reducing tolerance stack-up and improving concentricity.

Surface Finishing Services

Precision machining is incomplete without proper finishing.

Common options include:

- Anodizing (Type II, Type III / hard anodizing)

- Powder coating

- Electroless nickel plating

- Polishing, brushing, bead blasting

Surface finishing improves corrosion resistance, wear resistance, and visual quality.

Understanding Tolerances: What “Precision” Really Means

Not all tolerances are created equal.

Typical Tolerance Ranges

- Standard CNC machining: ±0.01 mm

- High-precision machining: ±0.005 mm

- Ultra-precision components: ±0.002 mm (application-specific)

Important: Tighter tolerances increase cost exponentially. A professional supplier of precision cnc machining services will question unnecessary specifications and suggest alternatives.

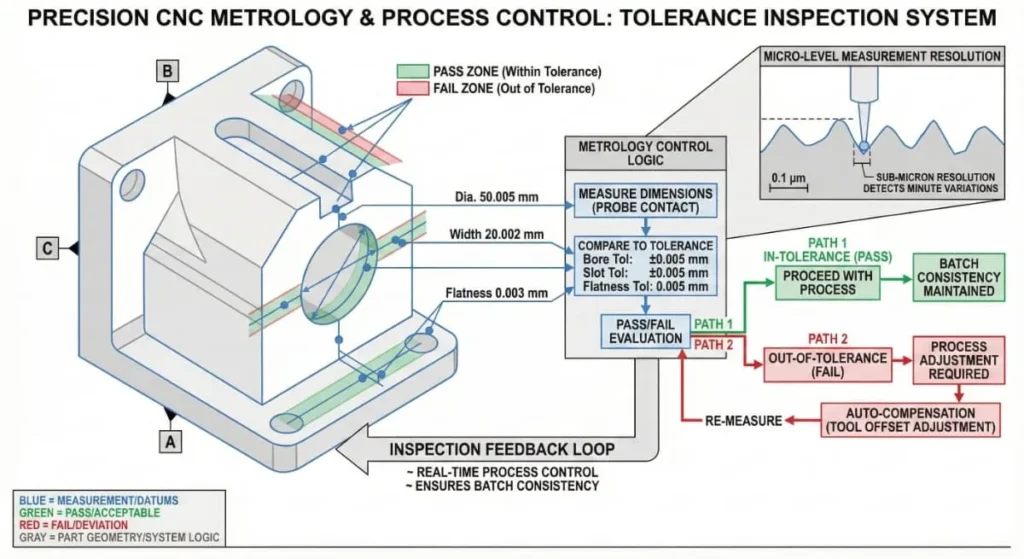

How Precision Is Controlled

- In-process probing

- Tool wear monitoring

- Climate-controlled inspection environments

- CMM inspection (Zeiss, Hexagon)

- First Article Inspection (FAI) reports

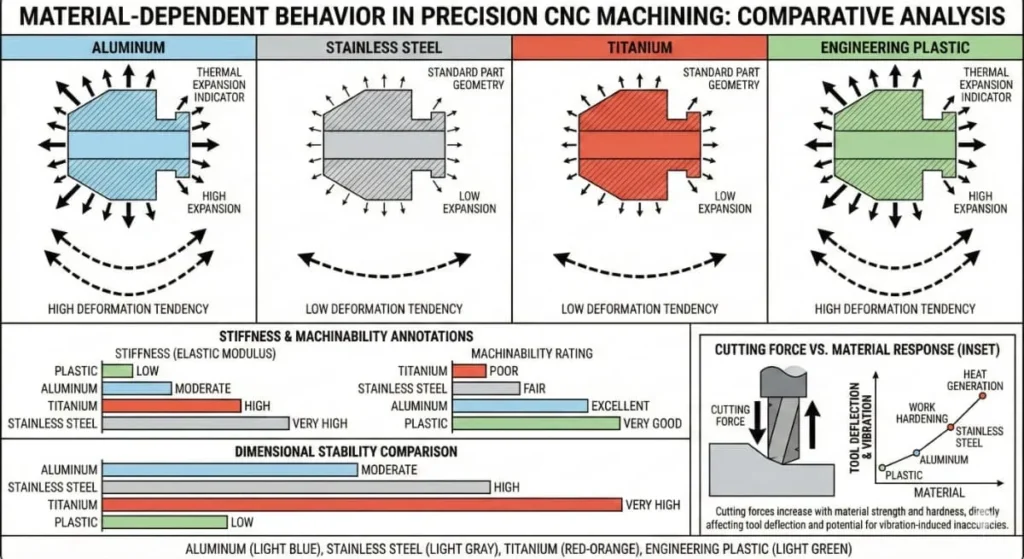

Materials Used in Precision CNC Machining Services

Common Metals

- Aluminum (6061, 7075)

- Stainless steel (304, 316, 17-4PH)

- Carbon steel

- Brass and copper

- Titanium (Grade 2, Grade 5)

Engineering Plastics

- POM (Delrin)

- Nylon

- PEEK

- PTFE

- ABS

Each material requires specific cutting strategies to maintain dimensional stability and surface integrity.

Always request material certificates (COA) to ensure compliance with ASTM or ISO standards.

Quality Standards & Certifications (E-E-A-T Focus)

Reputable China machining services follow international quality systems, including:

- ISO 9001 – Quality Management

- ISO 13485 – Medical manufacturing

- AS9100 – Aerospace standards

Quality documentation typically includes:

- Material traceability

- Dimensional inspection reports

- Surface finish verification

- Batch consistency records

These documents are critical for buyers in regulated industries.

How to Evaluate a Precision CNC Machining Supplier

Step-by-Step Checklist

- Review Equipment List

Look for 5-axis machines, modern CNC controls, and CMMs. - Ask for Sample Inspection Reports

Real reports reveal real capability. - Evaluate Engineering Communication

Questions should be answered clearly and technically. - Request DFM Feedback

A true manufacturer improves your design instead of just quoting it. - Confirm IP Protection

NDAs and internal data controls are essential.

China vs Local CNC Suppliers: Georgia & Savannah Perspective

Many buyers searching for precision cnc machining services Georgia or precision cnc machining services Savannah are comparing local and overseas suppliers.

When Local Suppliers Make Sense

- Extremely urgent turnaround

- ITAR-restricted components

- On-site engineering collaboration required

When China Machining Services Are Better

- Complex geometries

- Medium-volume production

- Cost-sensitive projects

- Multi-process parts with finishing

For many companies, China offers the best balance of precision, scalability, and cost.

Common Mistakes Buyers Make When Sourcing Precision CNC Machining Services

- Choosing suppliers based on price alone

- Ignoring tolerance feasibility

- Failing to validate inspection capability

- Skipping first-article approval

- Assuming all CNC shops are equal

Avoiding these mistakes can save months of delays and significant cost.

FAQ: Precision CNC Machining Services

What tolerances can you hold?

Typically ±0.005 mm, tighter upon evaluation.

Do you support low-volume production?

Yes. We specialize in high-mix, low-to-medium volume manufacturing.

What file formats do you accept?

STEP or IGES files are preferred. PDFs are acceptable for quoting.

How do you ensure batch consistency?

Standardized processes, tool management, and documented inspections.

Conclusion: Choosing the Right Precision CNC Machining Partner

Selecting a supplier for precision cnc machining services is not just about machines — it’s about process control, engineering mindset, and communication reliability.

Modern China machining services combine:

- Advanced CNC technology

- Skilled engineers

- International quality standards

- Cost efficiency without sacrificing precision

Whether you are an engineer validating a new design, a procurement manager sourcing globally, or a buyer comparing precision cnc machining services Georgia or Savannah options, the right partner protects your timeline, quality, and reputation.

Call to Action

If you are sourcing custom, non-standard parts and need a supplier that truly understands cnc precision machining services:

Upload your drawings today for a free DFM and manufacturability review.

Our engineers will respond with clear feedback, transparent pricing, and realistic lead times — no pressure, no obligation.