Medical CNC Machining Services: Engineering Standards, Processes, and Supplier Selection

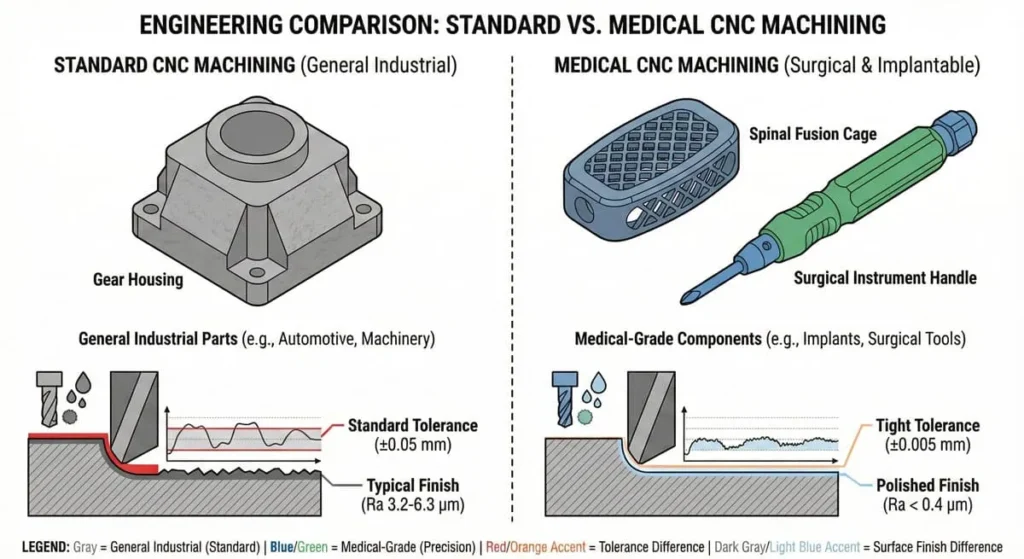

When manufacturing components used in medical devices, precision is not a selling point — it is a regulatory and functional requirement.

Medical CNC machining services operate under constraints that do not exist in general industrial machining: tighter tolerances, material traceability, contamination control, and documentation discipline.

This article serves as a technical reference guide for engineers and procurement teams evaluating medical CNC machining services, particularly when sourcing from China or overseas suppliers. Rather than focusing on marketing claims, it explains how medical machining actually differs at the process level, where failures typically occur, and what to verify before production begins.

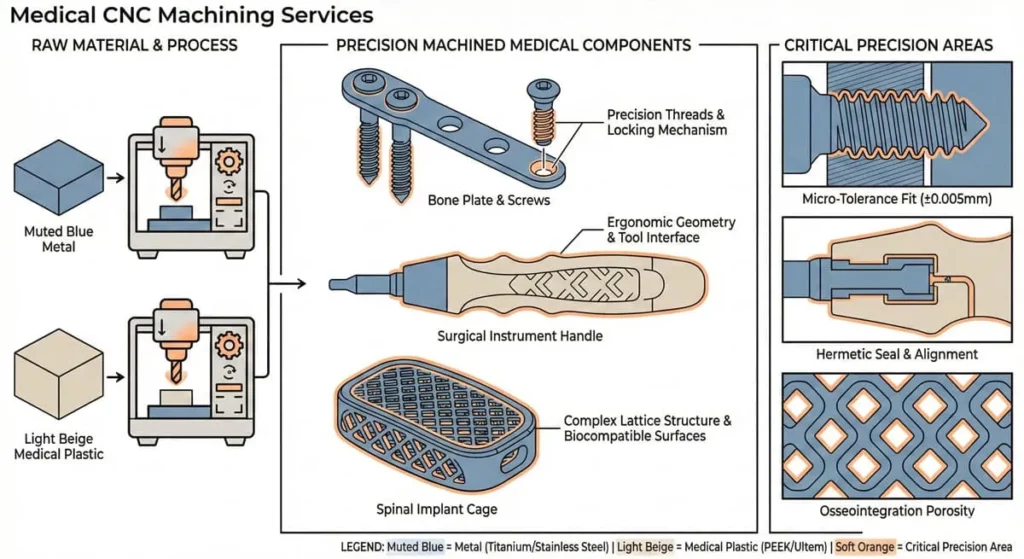

1. What Defines Medical CNC Machining Services (Beyond Standard CNC)

Medical CNC machining services are fundamentally different from general CNC machining services in three areas:

1.1 Tolerance Is Function-Critical, Not Cosmetic

In many medical applications, tolerance directly affects:

- Implant fit and load distribution

- Surgical instrument motion smoothness

- Seal integrity in diagnostic devices

Typical tolerance ranges include:

- ±0.01 mm for standard medical components

- ±0.005 mm or tighter for implants and precision instruments

These tolerances must be repeatable, not just achievable once.

1.2 Material Traceability Is Mandatory

A medical CNC machining service must maintain:

- Heat number traceability

- Material certificates (MTR / COA)

- Batch-level production records

Without traceability, even a dimensionally perfect part may be unusable in regulated medical supply chains.

1.3 Process Discipline Matters More Than Machine Brand

Advanced machines alone do not qualify a shop as a medical CNC machining service. What matters is:

- Tool segregation (especially titanium vs carbon steel)

- Coolant control and contamination prevention

- Documented SOPs and revision control

These process details are where many suppliers fail audits.

2. Core CNC Processes Used in Medical Applications

Medical CNC machining services rely on a limited set of highly controlled processes.

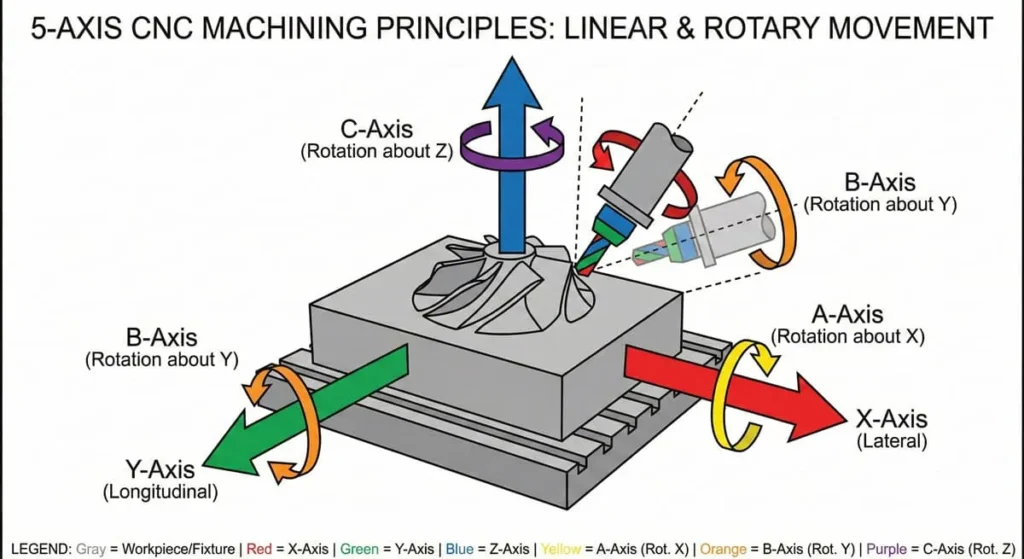

2.1 5-Axis CNC Machining for Complex Medical Geometry

5-axis machining is essential for:

- Orthopedic implants

- Anatomical components

- Parts with compound angles or undercuts

Key benefits include:

- Fewer setups → reduced cumulative error

- Improved surface consistency

- Better geometric accuracy for organic shapes

However, 5-axis machining for medical parts requires toolpath validation and vibration control, not just machine capability.

2.2 CNC Swiss Turning for Small, Slender Medical Parts

Swiss-type CNC turning is commonly used for:

- Bone screws

- Dental implants

- Endoscopic components

The guide bushing system minimizes deflection, which is critical when machining long, thin parts to medical tolerances.

2.3 CNC Milling for Medical Housings and Instruments

CNC milling remains the primary process for:

- Surgical instrument bodies

- Medical device housings

- Diagnostic equipment components

In medical CNC machining services, milling parameters are often conservative to maintain surface integrity and dimensional stability.

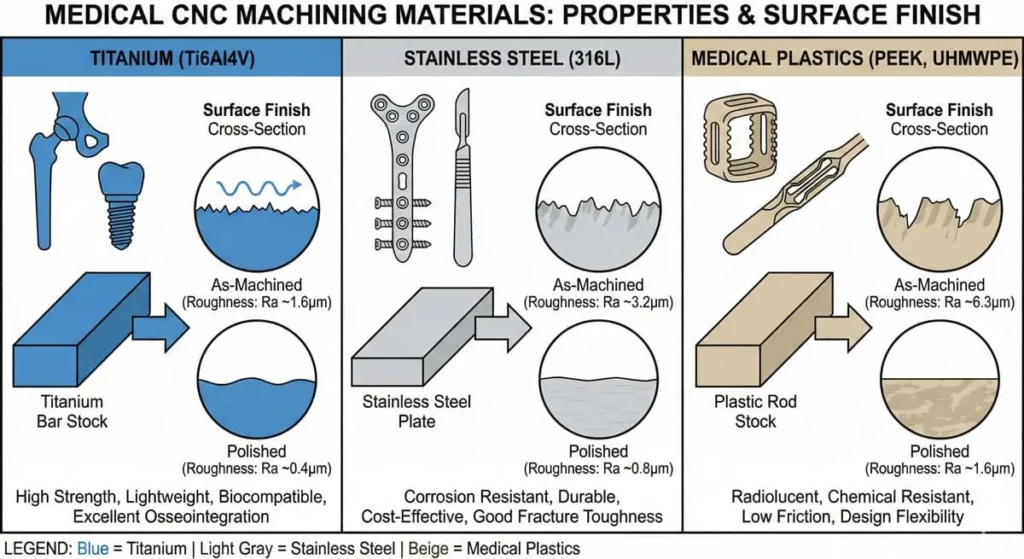

3. Materials Commonly Used in Medical CNC Machining Services

Material selection directly impacts machining strategy and post-processing.

3.1 Titanium Alloys (Ti-6Al-4V / ELI)

Titanium is widely used for implants due to its biocompatibility and strength-to-weight ratio.

Machining challenges include:

- Poor thermal conductivity

- Rapid tool wear

- Risk of surface smearing

Medical CNC machining services typically use:

- Specialized carbide tooling

- High-pressure coolant systems

- Strict tool-life monitoring

3.2 Stainless Steel (316L, 17-4PH)

- 316L: Implant-grade corrosion resistance

- 17-4PH: High strength for surgical instruments

Surface condition and passivation quality are critical for long-term corrosion resistance.

3.3 Medical-Grade Plastics (PEEK, Ultem, UHMWPE)

High-performance plastics are used for:

- Lightweight implants

- Insulating components

- Wear surfaces

Improper machining can introduce internal stress, leading to cracking during sterilization.

Experienced medical CNC machining services often anneal materials before and after machining.

4. Surface Finishing Is a Functional Requirement

In medical CNC machining services, surface finish affects:

- Bacterial adhesion

- Sterilization effectiveness

- Wear behavior

Common medical surface treatments include:

- Electropolishing (stainless steel)

- Passivation

- Anodizing (aluminum, titanium)

- Controlled polishing

Visual defects are often treated as functional defects in medical applications.

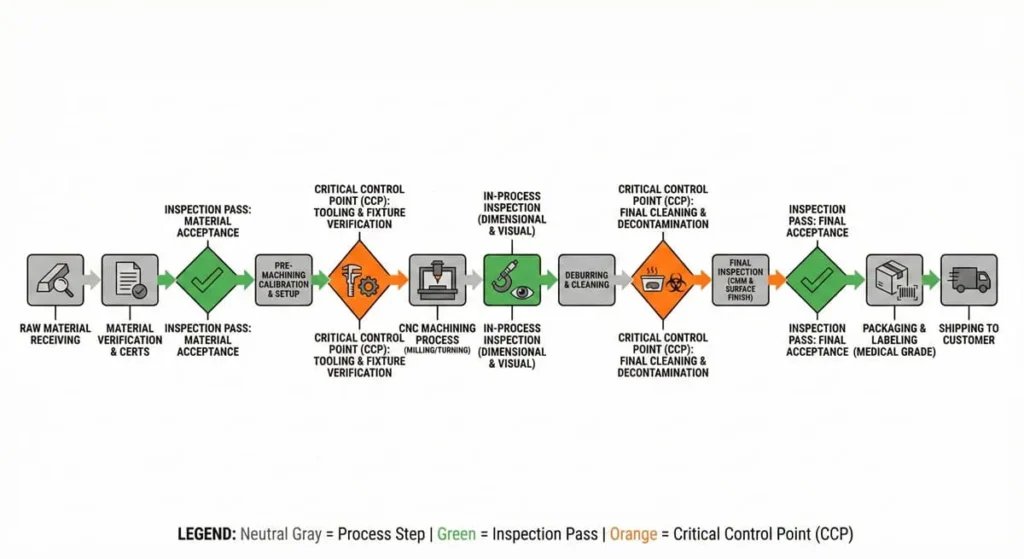

5. Quality Control Systems in Medical CNC Machining Services

Quality cannot be inspected into a part after production — it must be built into the process.

5.1 In-Process Inspection

- Tool wear monitoring

- Dimensional checks during production

- Early detection of drift

This prevents full-batch scrap.

5.2 CMM and GD&T Verification

Complex medical parts often require CMM inspection to verify:

- True position

- Profile

- Concentricity

A qualified medical CNC machining service provides dimensional reports with every critical shipment.

5.3 Documentation Delivered With Parts

Typical documentation includes:

- Material certificates

- Dimensional inspection reports

- Certificate of Compliance (CoC)

6. Sourcing Medical CNC Machining Services From China: Practical Considerations

China machining services have evolved significantly in the medical sector.

6.1 When China Is a Good Fit

- Medium-to-high volume production

- Cost-sensitive programs

- Multi-process integration

Many Chinese medical CNC machining services now operate under ISO 13485 and support regulated supply chains.

6.2 Risk Mitigation Checklist

Before selecting a supplier, verify:

- ISO 13485 certification

- Medical project experience

- English-speaking engineering support

- Clear DFM feedback process

A capable supplier will ask technical questions before quoting.

7. Common Failure Points in Medical CNC Machining Projects

Understanding failure modes is essential when evaluating suppliers.

- Tool contamination between materials

- Overly aggressive cutting parameters

- Missing traceability records

- Inadequate surface finishing validation

These issues rarely appear in quotations but often surface during audits or validation.

8. How to Start a Medical CNC Machining Project Correctly

A typical workflow includes:

- DFM review

- Material confirmation and certification

- Prototype machining

- Dimensional verification

- Controlled production ramp-up

Skipping early validation steps often leads to costly delays later.

Conclusion: Selecting a Medical CNC Machining Partner

Medical CNC machining services are not interchangeable with general precision machining.

The right supplier must demonstrate process control, documentation discipline, and real-world experience with medical failure modes.

When evaluating medical CNC machining services — especially overseas — prioritize engineering transparency over marketing language.

A supplier who understands where things go wrong is far more valuable than one who only promises what can go right.