The Ultimate Guide to Polishing VS Buffing: Mirror Finishes, Ra Specs & Vapor Polishing

By The CNMP Expert Team

You have machined a part. You have bead blasted it. But for some applications—like a medical implant, a luxury watch case, or an optical lens—”smooth” isn’t enough.

You need Perfection. You need a mirror.

This is where Polishing and Buffing come in.

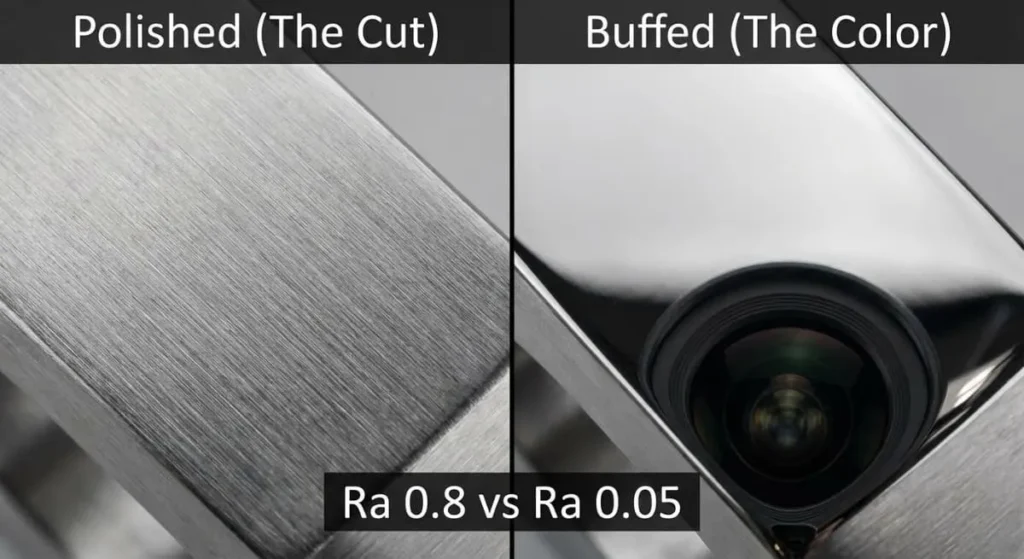

While often used interchangeably, they are two distinct steps in a sequence.

- Polishing is the aggressive removal of material to level the surface (The “Cut”).

- Buffing is the gentle smoothing of the surface to create a shine (The “Color”).

In this final chapter of our Surface Finish Series, we break down the art of achieving the perfect Ra 0.05 finish, explore the “magic” of Vapor Polishing for plastics, and reveal why your polishing shop might be a ticking time bomb.

Polishing and Buffing: What is the Difference?

The “Cut” vs. The “Color”.

1. Polishing (The Aggressor)

- The Tool: Abrasive belts or grinding wheels with glued grit.

- The Action: It acts like sandpaper. It aggressively removes deep tool marks, pits, and burrs. It leaves a directional “brushed” pattern of very fine scratches.

- The Result: A uniform, clean surface, but not reflective. Ra ~0.4μm.

2. Buffing (The Refiner)

- The Tool: Soft cloth or felt wheels carrying a loose abrasive compound (wax bar).

- The Action: It “moves” the metal rather than just cutting it. It smooths out the microscopic peaks left by polishing.

- The Result: A non-directional, mirror-like finish. Ra < 0.1μm.

Expert Insight:

“You cannot buff a raw machined part. You must Polish it first to remove the 0.05mm tool marks, THEN Buff it to make it shine. Skipping steps leads to the ‘Orange Peel’ effect where the part shines but looks wavy.”

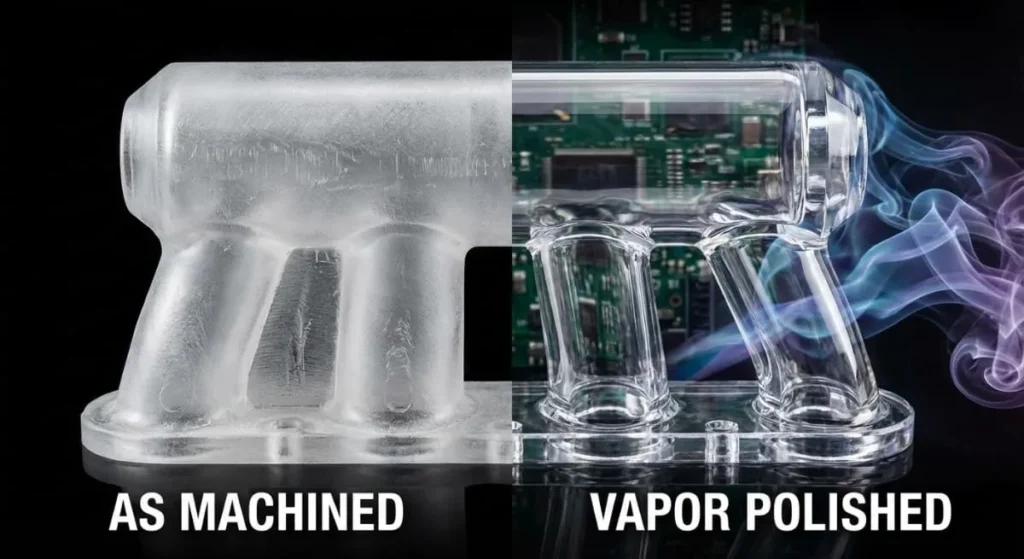

The “Magic” of Vapor Polishing (For Plastics)

Turning cloudy plastic into glass.

If you machine Clear Polycarbonate (PC) or Acrylic (PMMA), it comes off the machine looking cloudy and white. You can’t mechanically buff it easily—it melts.

The Solution: Vapor Polishing.

- The Process: We boil a specialized solvent (like Weld-On 4) into a gas. We then expose the plastic part to this vapor.

- The Reaction: The vapor melts only the outer molecular layer of the plastic. It reflows instantly, filling in all the microscopic scratches.

- The Result: The part becomes optically clear (transparent) in seconds, inside and out.

- The Risk:Crazing (Stress Cracking). If the plastic has internal stress, the chemical will cause it to shatter like a spiderweb.

- Fix: We MUST anneal (bake) the plastic parts before vapor polishing to release stress.

Electropolishing: The “Chemical” Mirror

Standard for Stainless Steel.

For complex Stainless Steel parts (like manifolds or valves), mechanical buffing is impossible because the wheel can’t reach inside.

Enter Electropolishing.

- How it works: It is the reverse of plating. We put the part in an acid bath and apply electricity to remove material.

- The Physics: Electricity concentrates on the “peaks” of the surface roughness, dissolving them faster than the “valleys.”

- The Result: A microscopically smooth, ultra-clean surface that is 30x more corrosion resistant than raw stainless.

- Application: Medical instruments, food processing, semiconductor.

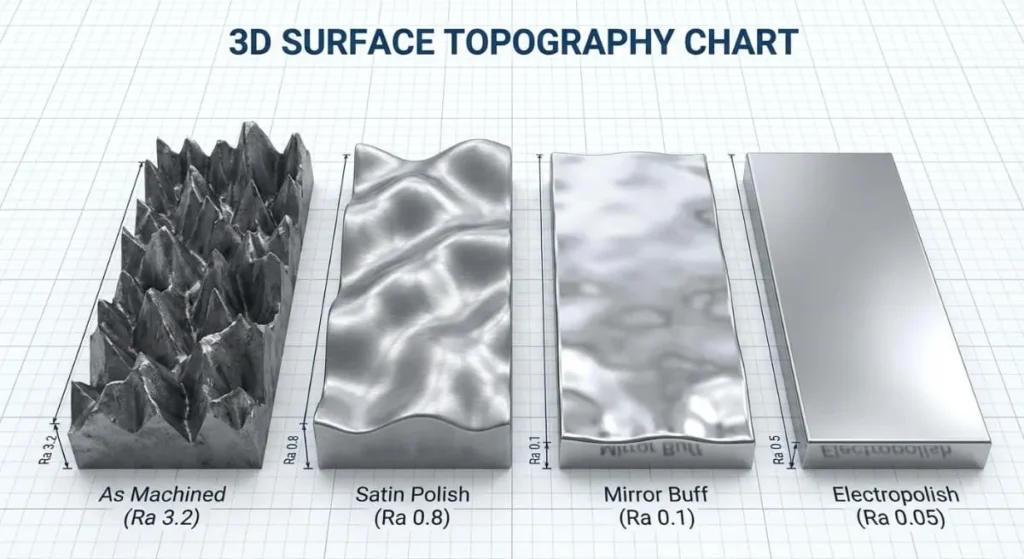

Engineering Specs: The Ra Roughness Ladder

How to specify “Shiny” on a drawing.

Don’t write “Mirror Finish.” It’s subjective. Use Ra values.

| Finish Class | Process Steps | Ra (μm) | Application | Cost |

| Fine Machined | CNC Finishing Pass | 1.6 – 3.2 | Industrial Brackets | $ |

| Satin Polish | 320 Grit Belt | 0.8 – 1.2 | Brushed Aluminum | $$ |

| Fine Polish | 600 Grit + Cut Buff | 0.4 – 0.8 | Food Equipment | $$$ |

| Mirror | 2000 Grit + Color Buff | 0.05 – 0.1 | Optical / Cosmetic | $$$$ |

| Super Mirror | Lapping / Electropolish | < 0.05 | Semiconductor | $$$$$ |

Shop Floor Dangers: The Explosion Risk

What most designers don’t know.

Aluminum Polishing is Dangerous.

When we grind or polish aluminum, we generate fine aluminum dust.

- The Hazard: Aluminum dust is highly explosive. If a steel screw hits the grinding wheel and creates a spark, the dust collector can explode with the force of a bomb.

- The Safety Protocol: At CNMP, we use Wet Down-Draft Tables (water filtration) for all aluminum polishing and buffing. We never mix steel and aluminum grinding in the same room.

Why this matters to you:

If your supplier is cheap, they might be skipping these safety measures. A factory fire means your molds and parts are gone. Always ask about their EHS (Safety) protocols.

Summary: Which Polish Do You Need?

- Choose Mechanical Polishing/Buffing If:

- You need a cosmetic mirror finish on the outside of a part.

- Material is Aluminum, Brass, or Steel.

- Choose Vapor Polishing If:

- Material is Clear Plastic (PC, Acrylic, Ultem).

- You need optical transparency (Windows, Lenses).

- Choose Electropolishing If:

- Material is Stainless Steel.

- You need the inside of holes to be smooth.

- Application is Medical or Food Grade.

This concludes our Surface Finish Series.

From the rugged protection of Anodizing to the perfection of Mirror Polishing, CNMP has the technology to make your parts perform as good as they look.

Contact CNMP for a quote on your precision finished parts today.