1) What Is Bead Blasting? (Definition + the real physics)

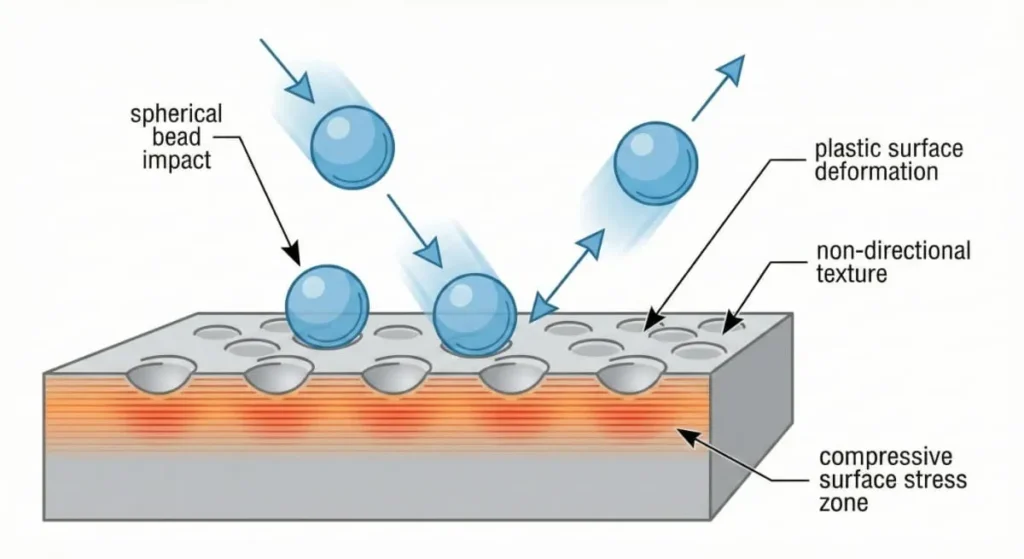

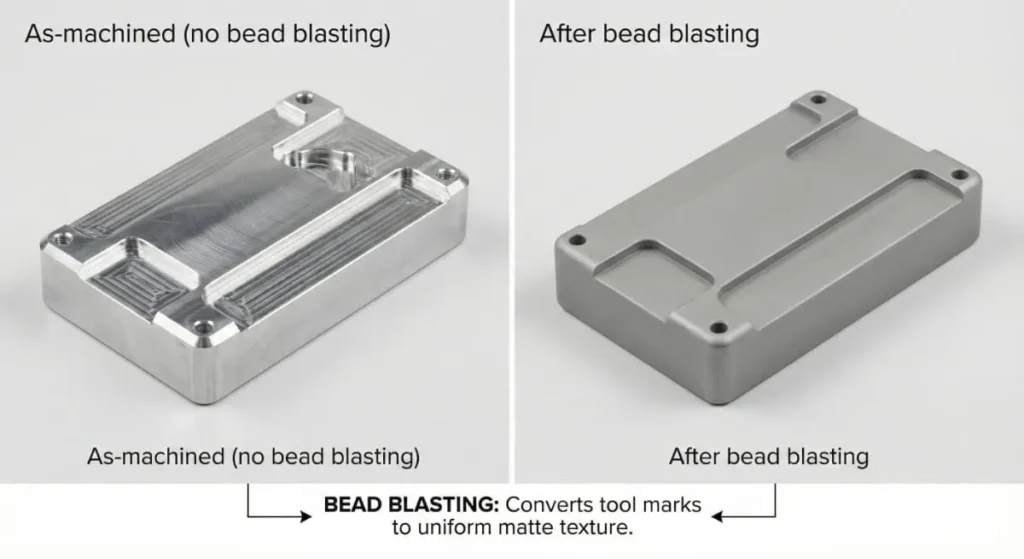

What is bead blasting? Bead blasting is a compressed-air surface finishing process that propels spherical media—most commonly glass beads or ceramic beads—against a workpiece to create a uniform satin/matte texture, clean light oxidation, and blend minor surface inconsistencies.

A key point for engineers: bead blasting is often described as “peening-like” because the spherical media tends to deform the surface micro-topography rather than aggressively cut it. However, it is not automatically the same thing as controlled shot peening. Shot peening is usually specified and verified by intensity/coverage standards (e.g., Almen), while bead blasting is more commonly specified by appearance, Ra, and masking requirements.

In practical CNC production, bead blasting is used to:

- Hide directional tool marks and unify the cosmetic appearance

- Prepare surfaces for anodizing, plating, paint, or adhesive bonding (depending on media choice)

- Provide a consistent tactile feel (consumer electronics housings are a classic example)

- Clean weld tint or light oxidation on suitable materials (with correct contamination control)

2) Where Bead Blasting Fits in CNC Manufacturing (What it can’t fix)

Bead blasting is excellent at blending light machining marks. It is not a magic eraser for serious defects.

Bead blasting typically will not fix:

- Deep scratches, heavy chatter, gouges, dents

- Tool marks that are deep enough to create “shadowing” after blasting

- Flatness/warp issues caused earlier in machining

- Porosity or casting pits (it may make them more visible by uniforming the surrounding texture)

A reliable shop-floor rule: if a defect is visible from multiple angles on an as-machined part, bead blasting will often make it less directional but not necessarily invisible. For high-cosmetic parts, plan for pre-sanding or spot finishing before bead blasting.

3) Equipment Fundamentals (Cabinet, Gun, Suction vs Pressure Pot, Air Quality)

A consistent bead blasting finish is the output of a controlled system, not just a nozzle and air.

3.1 Blast cabinet (containment + repeatability)

For precision parts, bead blasting is usually performed in a sealed blast cabinet to:

- Maintain media cleanliness and recyclability

- Control dust

- Improve operator visibility and finish consistency

- Reduce cross-contamination risks between materials

3.2 Suction (siphon) vs pressure pot systems

Both can produce good results; they behave differently.

Suction/siphon systems

- Pros: gentler impact, easier to run continuously, often preferred for cosmetic bead blasting aluminum

- Cons: lower media velocity, slower cleaning

Pressure pot systems

- Pros: higher velocity and throughput; useful for tougher oxides/coatings (with the correct media)

- Cons: easier to over-blast soft alloys if not controlled; more sensitive to setup and operator technique

3.3 Compressed air: PSI is not enough—CFM and dryness matter

Many inconsistent finishes blamed on “bad media” are actually caused by air issues.

- Pressure (PSI): typical working ranges for glass bead blasting are often ~40–80 PSI for cosmetic work (actual values depend on bead size, nozzle, distance, and material). Excess pressure can increase bead fracture and dust, hurting finish stability.

- Flow (CFM): insufficient CFM causes surging and inconsistent texture.

- Moisture control: water in air lines causes media clumping and “spitting,” creating patchy results. A dryer + water separator is not optional for professional bead blasting.

- Oil contamination: oil carryover can smear parts and ruin subsequent anodizing/painting.

3.4 Dust collection

Dust collection affects:

- Visibility (operator can hold consistent distance and sweep speed)

- Media life (separating reusable beads from fines)

- Safety (particulate exposure control)

4) Media Selection: Glass vs Ceramic vs Aluminum Oxide (and the “Sand Bead Blasting” Confusion)

The media you choose largely determines whether bead blasting produces a premium satin finish or a rough, paint-ready profile.

4.1 Glass beads (the standard for cosmetic finishing)

Glass bead blasting media is the default choice for many CNC parts:

- Produces a bright, satin-to-matte look

- Tends to blend tool marks without aggressive cutting

- Recyclable for many cycles (media management matters)

Best uses:

- Cosmetic finishing for housings, brackets, covers

- Pre-anodize preparation on aluminum (with correct process control)

- Light cleaning on stainless or titanium with dedicated media

4.2 Ceramic beads (longer life, potentially more consistent on volume)

Ceramic beads are harder and typically more durable than glass:

- Longer media life can improve consistency across long production runs

- Can be slightly more aggressive depending on grade and size

Best uses:

- Higher-volume production where stability and media life matter

- When you need a consistent “factory satin” across batches

4.3 Aluminum oxide / grit (aggressive—often becomes “sandblasting” territory)

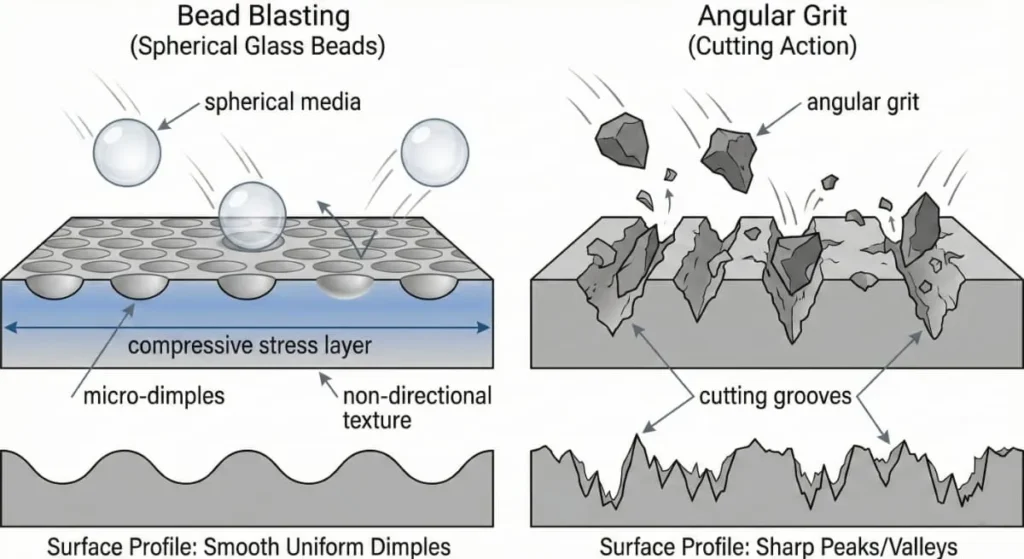

Aluminum oxide is angular and cuts the surface:

- More suitable for coating removal, heavy cleaning, or strong mechanical keying for paint/bonding

- Produces a duller, rougher profile than classic bead blasting

If the goal is a refined satin cosmetic finish, aluminum oxide is usually not the right tool.

4.4 The “sand bead blasting” term (clarify before you quote)

You may see customers request sand bead blasting. In many RFQs this phrase is a mismatch—people blend terms from different processes.

Practical clarification script:

- If they want a smooth satin/matte cosmetic finish → recommend glass/ceramic bead blasting

- If they want a rough, etched surface for coatings → recommend angular grit (often called sandblasting)

Always confirm with a reference photo, a target Ra range, or a sample part. Misinterpreting “sand bead blasting” is a classic cause of rework disputes.

5) Process Parameters That Control Appearance and Consistency

To get repeatable bead blasting results, you must control the variables that shape texture:

- Media size / mesh

- Coarser beads create a more noticeable texture and can hide heavier tool marks

- Finer beads produce a softer, more “velvet” matte

- Air pressure (PSI)

- Higher PSI increases impact energy (faster, but higher risk of over-blasting soft metals)

- Too high can break beads, creating dust and inconsistent cutting-like behavior

- Nozzle distance

- Too close: risk of localized over-texture, edge rounding, “hot spots”

- Too far: poor cleaning and uneven finish

- Angle of attack

- Perpendicular blasting tends to texture more uniformly

- Shallow angles can create directional “striping” on large faces

- Sweep speed and overlap

- The operator’s motion is a major variable; inconsistent overlap produces visible bands

- Part temperature and handling

- Warm parts + oily fingerprints can create blotchy anodizing results after bead blasting aluminum

If your part is highly cosmetic, treat bead blasting like a controlled finishing operation: documented settings, dedicated media, and a first-article appearance approval.

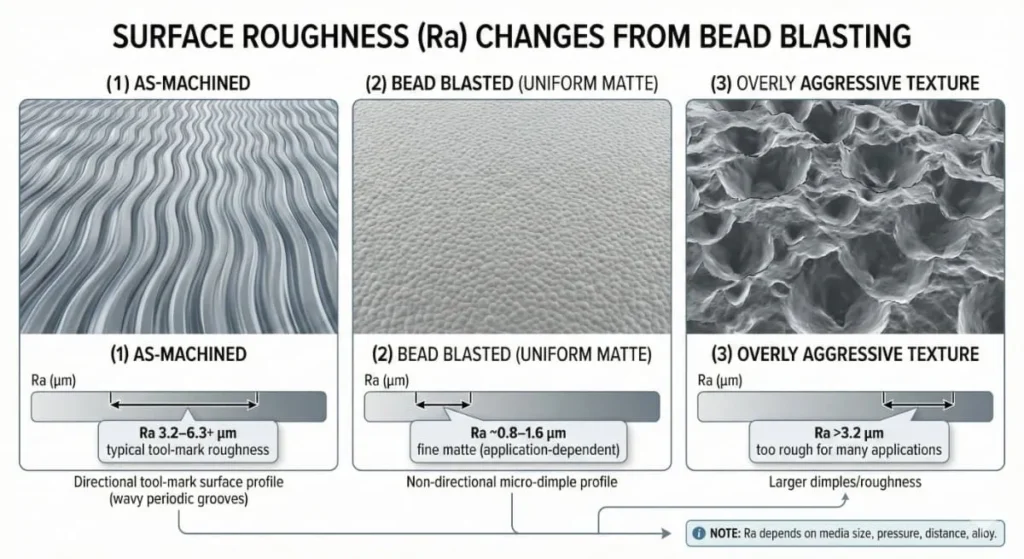

6) Surface Roughness (Ra): Realistic Targets, Measurement, and How to Call It Out

Subjective notes like “smooth finish” are not engineering specs. Use Ra (Roughness Average) and define where and how it is measured.

6.1 Ra basics (and measurement standards)

- Ra is the arithmetic average roughness value

- Measurement is commonly guided by standards such as ISO 4287 / ISO 4288 (measurement method and evaluation lengths matter)

6.2 Typical Ra guidance (practical ranges, not promises)

Actual Ra after bead blasting depends on alloy hardness, original machining marks, bead size, PSI, distance, and exposure time. The ranges below are typical starting points for discussion and should be validated on your geometry:

| Finish intent | Typical media approach | Typical Ra outcome (often seen) |

|---|---|---|

| Soft matte, minimal texture | Fine glass beads / controlled low PSI | ~0.8–1.6 µm (application-dependent) |

| Classic satin cosmetic | Medium glass beads (common production choice) | ~1.0–2.5 µm |

| Heavier texture / more “frosted” | Coarser beads or more aggressive settings | ~1.6–3.2 µm (or higher) |

6.3 A practical drawing callout example (copy-paste)

For general cosmetic CNC parts, a common, procurement-friendly callout is:

FINISH: Bead blasting to uniform matte appearance. Target Ra 1.6–3.2 µm unless otherwise specified.

Mask threads, bearing bores, sealing surfaces (see notes/sections).

If your part will be anodized, specify the appearance requirement explicitly, because bead blasting aluminum strongly affects final color uniformity.

7) Dimensional Impact & Tolerance Risk (Press fits, sealing faces, critical features)

Bead blasting typically changes dimensions by microns, but microns matter in fits and sealing.

Where bead blasting can cause functional issues:

- Press fits / bearing seats (e.g., H7 bores): even small changes in surface condition can alter insertion force or effective contact behavior

- Sealing faces: texture can create leak paths or reduce seal performance

- Threads: media impact can flatten crests or embed debris, leading to seizure during assembly

- Sharp cosmetic edges: over-blasting can round edges more than expected

A good engineering habit is to classify surfaces into:

- Blast OK (cosmetic)

- Blast OK with limits (appearance-only, controlled)

- Do not blast / must mask

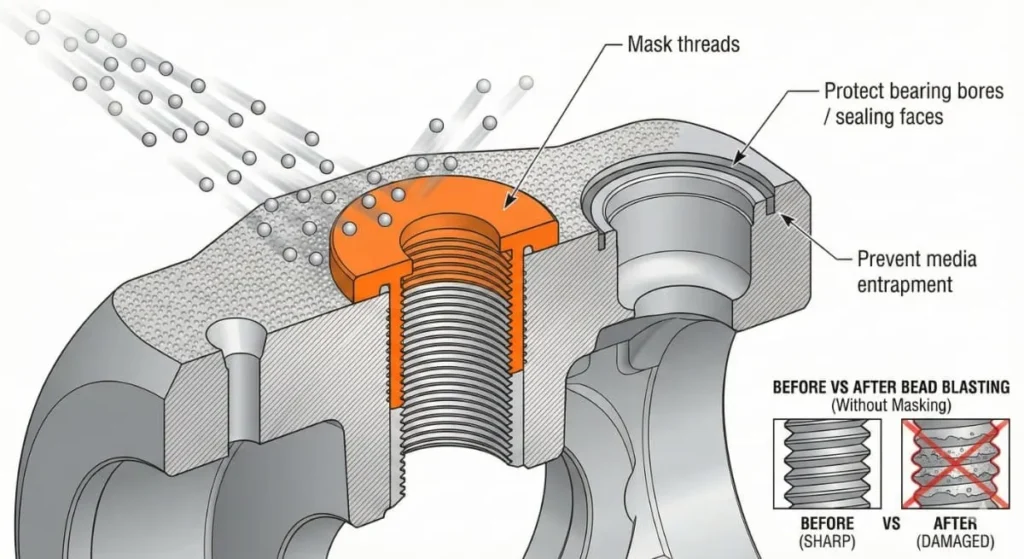

8) Masking: The #1 Cause of Scrap—and How to Specify It on Drawings

In real production, the most common bead blasting failures are not “wrong beads.” They are missing masking instructions.

8.1 What must be masked (default rule)

Mask these unless you explicitly approve blasting:

- All internal and external threads

- Bearing bores, precision bores, dowel holes

- Sealing surfaces (O-ring glands, vacuum faces, gasket lands)

- Critical datum features where texture affects function or measurement

8.2 Masking methods

- Silicone plugs/caps (excellent for threads and bores)

- High-strength blasting tape (flat sealing faces)

- Custom fixtures or shields (repeatability on production runs)

- Sacrificial fasteners (temporary bolts in threads; confirm cleanliness requirements)

Masking is manual labor and affects cost, but it is far cheaper than scrapping tight-tolerance parts.

8.3 Drawing language that prevents disputes (copy-paste)

Option A (general):

Mask all threads, bearing bores, sealing surfaces from bead blasting.

Option B (explicit zones):

Bead blasting applies only to surfaces marked “BB.” All other surfaces: NO BLAST.

Mask areas hatched in Section A-A.

Option C (when cleaning is critical):

After bead blasting: ultrasonic cleaning required. No residual media permitted in blind holes or internal cavities.

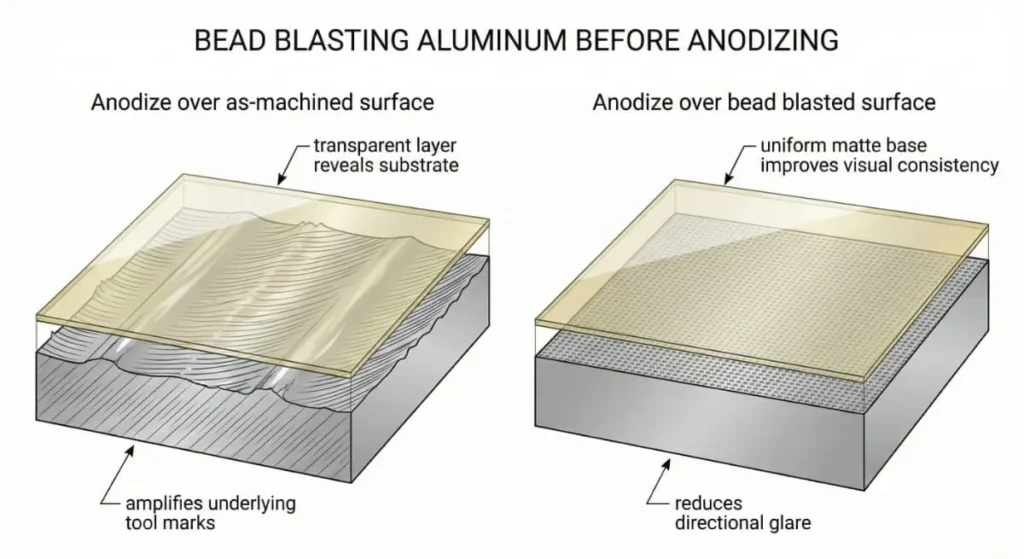

9) Bead Blasting Aluminum: Best Practices Before Anodizing (Type II / Type III)

Bead blasting aluminum is one of the most common—and most misunderstood—requests in CNC manufacturing.

9.1 Why bead blasting aluminum is used before anodizing

Anodizing forms a transparent/translucent oxide layer. It does not “hide” tool marks; it can make them more obvious. Bead blasting aluminum:

- Removes directional machining glare

- Creates a uniform, non-directional base texture

- Helps produce the deep, consistent “premium matte” look many designers want

9.2 Type II anodizing (decorative/color)

For Type II color anodizing, bead blasting aluminum is often the difference between:

- “You can see every toolpath in the color”

vs - “Uniform, high-end matte color”

Key control points:

- Use clean, dedicated media suitable for aluminum (avoid cross-contamination)

- Maintain consistent blast coverage to prevent shade variation

- Handle parts with gloves after blasting to avoid fingerprint-related dye differences

9.3 Type III hard anodizing (functional/wear)

Hard anodize thickness and wear behavior can be sensitive to surface condition. If you need a functional hardcoat:

- Consider finer media and tighter process control

- Avoid overly rough textures unless you want extra oil retention (application-dependent)

- Validate with test coupons or first-article inspection

9.4 A practical note for engineers

If the anodized part must match an existing product, specify:

- The bead blasting aluminum appearance standard (photo/swatch)

- The anodize type, color, and gloss level expectation

- Whether “two-tone” or “striping” is acceptable (often it is not)

10) Material-Specific Guidance (Stainless, Titanium, Copper/Brass, Plastics, 3D Printing)

10.1 Stainless steel (304 / 316L)

Bead blasting can remove light heat tint and unify appearance. Critical warning:

- Do not use media previously used on carbon steel. Embedded free iron can cause stainless to rust.

Use dedicated media and proper cleaning/passivation when required.

10.2 Titanium (e.g., Ti-6Al-4V)

Bead blasting is often used to reduce glare and produce a uniform matte. For medical or high-cleanliness applications:

- Confirm allowable media type and cleanliness standard

- Specify post-process cleaning

10.3 Copper and brass

Soft alloys can pit or smear if blasting is too aggressive:

- Use lower pressure and validate appearance on a sample

10.4 Engineering plastics (Delrin, PC, ABS)

Yes, bead blasting is possible, but heat and surface melting are risks:

- Lower PSI, faster passes, and careful media choice are essential

10.5 3D printed parts (SLS / DMLS)

Bead blasting can remove loose powder and soften layer-line appearance. However:

- Internal channels may trap media (design for clean-out or specify ultrasonic cleaning)

- Validate that the finish does not alter critical mating interfaces

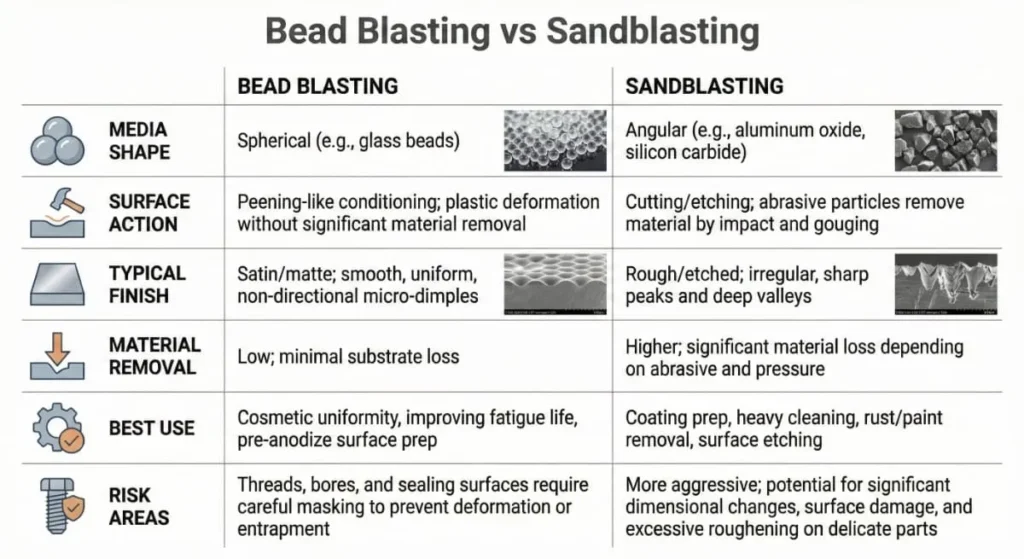

11) Bead Blasting vs Sandblasting (and vs Polishing/Tumbling/Shot Peening)

11.1 Bead blasting vs sandblasting (the most important confusion)

Bead blasting vs sandblasting is primarily about media shape and resulting surface mechanics:

| Feature | Bead blasting | Sandblasting / grit blasting |

|---|---|---|

| Media | Spherical glass/ceramic beads | Angular sand/garnet/aluminum oxide |

| Surface action | Peening-like conditioning | Cutting/etching |

| Typical finish | Satin / matte cosmetic | Rough / etched / coating prep |

| Material removal | Low (micron-level, variable) | Higher, more aggressive |

| Best for | Cosmetic unification, gentle cleaning | Rust removal, heavy stripping, strong anchor profile |

If your RFQ mentions sand bead blasting, clarify what finish you want. Many buyers mean “bead blasting” but use the wrong phrase.

11.2 Bead blasting vs polishing

- Polishing creates reflectivity and can be labor-heavy

- Bead blasting creates uniform matte and is generally more cost-effective for complex geometries

11.3 Bead blasting vs tumbling (vibratory finishing)

- Tumbling is efficient for large batches of small parts, but can heavily round edges

- Bead blasting is better for controlled cosmetic faces, complex geometry, and masked regions

11.4 Bead blasting vs shot peening

- Shot peening is typically specified by measurable peening intensity/coverage and targeted fatigue improvement

- Bead blasting is most often specified by appearance/Ra and can have peening-like effects, but should not be claimed as a fatigue-life solution unless validated and controlled

12) Quality Control & Acceptance Criteria (Appearance, Cleanliness, Contamination Control)

For automotive and industrial supply chains, disputes usually happen when “finish quality” is not defined.

12.1 Appearance acceptance (recommended)

Define these in your spec or PO:

- Viewing distance: e.g., 30–50 cm

- Lighting: e.g., diffuse white light, avoid direct glare

- Orientation: inspect from multiple angles to detect striping

- Reference: approved “golden sample” photo or physical panel

Suggested wording:

Finish shall be uniform matte with no visible striping, patchiness, or hot spots under diffuse light at 40 cm viewing distance. Minor variation on hidden surfaces acceptable.

12.2 Cleanliness acceptance (recommended)

Especially important for assemblies and anodized parts:

- No residual beads in threads, blind holes, internal pockets

- If needed: ultrasonic cleaning + drying + compressed air blow-out

- For stainless: contamination control (dedicated media) and optional passivation requirement

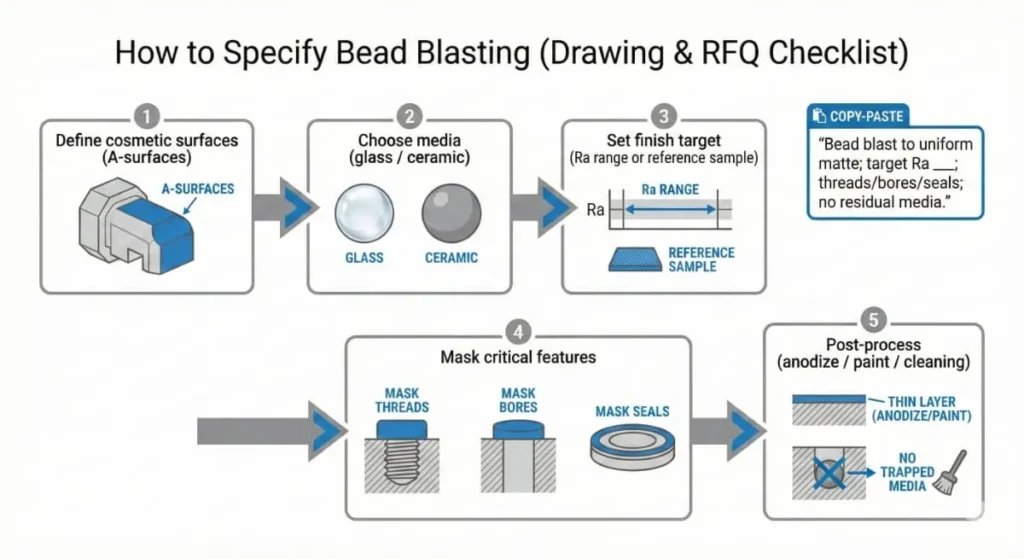

13) Procurement / RFQ Checklist + Copy-Paste Drawing Notes

To quote and produce bead blasting correctly, a supplier needs more than “blast it.”

13.1 RFQ checklist (send this with your CAD)

- Material and temper (e.g., 6061-T6, 7075-T6, 304, Ti-6Al-4V)

- Which surfaces require bead blasting (mark on drawing)

- Cosmetic level: “A-surface” vs hidden surfaces

- Target Ra (or reference sample/photo)

- Post-process: anodize type/color, plating, paint, bonding

- Masking list (threads/bores/seals)

- Cleanliness requirement (ultrasonic? no media in blind holes?)

- Quantity and batch size (consistency expectations change with volume)

- Any “do not round edges” requirement

- Packaging requirements to prevent scuffing after bead blasting

13.2 Drawing notes (copy-paste templates)

Template 1 (common for cosmetic aluminum + anodize):

Bead blasting aluminum to uniform matte appearance prior to anodizing. Target Ra 1.6–3.2 µm on cosmetic faces. Mask all threads, bearing bores, and sealing surfaces. No visible striping on cosmetic faces.

Template 2 (when blind holes exist):

After bead blasting: ultrasonic cleaning required. No residual media allowed in blind holes/internal cavities.

Template 3 (when fit is critical):

Do not bead blast press-fit bores and datum interfaces unless noted. Mask critical fits per drawing.

14) Common Defects & Troubleshooting

Defect: striping / banding on large flat faces

Likely causes:

- Inconsistent sweep speed or overlap

- Angle variation, poor visibility due to dust

Fix: - Improve dust collection, standardize gun distance/angle, use fixtures for repeatability

Defect: patchy “shadow” areas after anodizing

Likely causes:

- Uneven blasting coverage or inconsistent surface condition

- Fingerprints/oil after blasting

Fix: - Handle with gloves, tighten blasting pattern control, improve cleaning prior to anodize

Defect: thread seizure or gritty assembly feel

Likely causes:

- Threads not masked; residual beads trapped

Fix: - Mask threads; add cleaning requirement; consider temporary bolts plus cleaning validation

Defect: warping on thin parts

Likely causes:

- Over-blasting thin walls; unbalanced blasting (one side heavily treated)

Fix: - Reduce PSI, fixture parts, blast both sides evenly, validate early

15) FAQ

Q1: What is bead blasting used for on CNC parts?

What is bead blasting used for most often? Cosmetic unification (satin/matte), light cleaning, and creating a consistent base texture before anodizing or coatings—especially on bead blasting aluminum projects.

Q2: Does bead blasting remove material?

Yes, but usually at a very small scale. The practical risk is less about bulk removal and more about how surface texture affects fits, seals, and threads. If you have tight tolerances, mask critical features and validate with inspection.

Q3: Is bead blasting vs sandblasting just different names?

No. Bead blasting vs sandblasting differs in media geometry and surface action. Bead blasting typically yields a smoother satin finish; sandblasting/grit blasting is more aggressive and etches a rougher profile.

Q4: What does “sand bead blasting” mean on an RFQ?

Sand bead blasting is often a mixed term. Confirm whether the intent is a smooth cosmetic bead blasting finish or a rough sand/grit-blasted profile for coating adhesion.

Q5: Should I bead blast before anodizing?

For many cosmetic parts, yes—especially bead blasting aluminum housings or panels where you want uniform color and low glare. For functional hard anodize, use finer media and validate performance requirements.

16) Conclusion + Next Steps

Bead blasting is one of the most cost-effective ways to transform an as-machined component into a professional, uniform product surface—especially when the goal is a consistent matte/satin look and a stable base for anodizing. The difference between a premium result and scrap usually comes down to three things: media selection, process control, and masking.

If you want to minimize rework and speed up quoting, send your supplier: (1) marked-up blast zones, (2) masking list, (3) target Ra or reference photo, and (4) post-process requirements (anodize/plating/paint). That is how you get bead blasting results that are repeatable, inspectable, and procurement-friendly.

Next step (recommended): approve a first-article “appearance standard” sample for your bead blasting + anodizing combination, then lock the media type and settings for production consistency.

Contact Us and Let’s start your project.