The Ultimate Guide to CNC Surface Finish: Function, Aesthetics & The Tolerance Trap

By The CNMP Expert Team

You’ve selected the perfect material. You’ve optimized the geometry. But your part isn’t finished until it’s… finished.

Surface treatment is not just about making parts look pretty. It’s about corrosion resistance, surface hardness, electrical conductivity, and reducing friction. However, it is also the stage where most precision errors occur.

The most common failure we see? A designer specifies a tight tolerance ($\pm 0.01$mm) but forgets that the surface coating adds thickness, causing the part to be oversized.

This guide breaks down the 4 major categories of surface finish, analyzing them through the lens of The Design Engineer (Function) and The Shop Floor Manager (Fit & Cost).

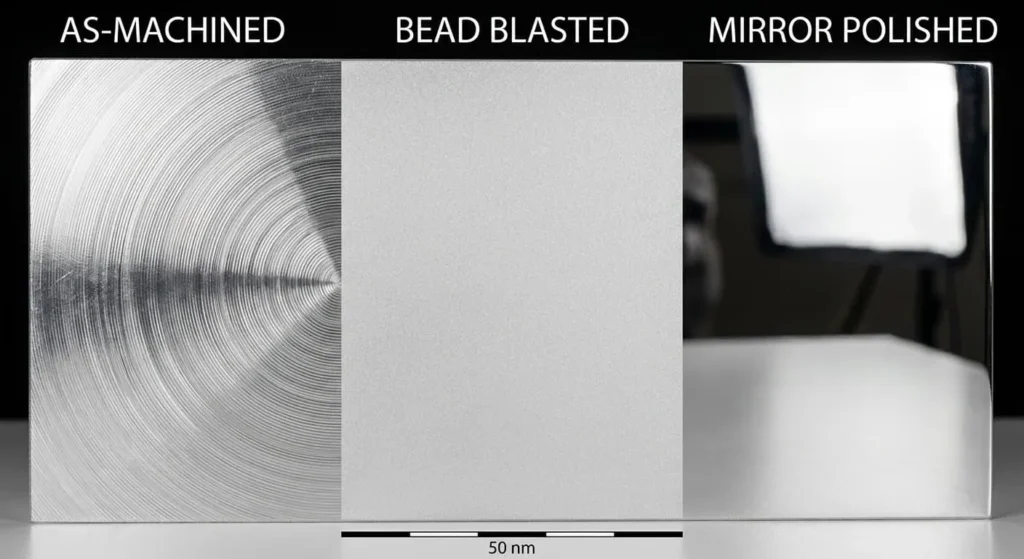

1. Mechanical Surface Finish: The Texture of Metal

Physical alteration of the surface. No chemicals added.

| Sruface Finish Type | Description | The Design Engineer (Function) | The Shop Floor Manager (Reality) | Cost |

| As-Machined | Raw surface finish left by the CNC cutter. Visible tool marks. | Ra 1.6 – 3.2 $\mu m$. Best for internal components where aesthetics don’t matter. Tightest possible tolerance control. | The Fastest. No extra steps. We just deburr the edges and ship it. | $ |

| Bead Blasting | Spraying glass or sand beads to create a matte texture. | Ra 0.8 – 1.6 $\mu m$. Reduces reflection. Hides minor tool marks. Uniform matte look. | Warning: Blasting removes a tiny amount of material. Do not blast bearing bores or threads! We must mask them, which adds cost. | $$ |

| Polishing / Mirror | Grinding and buffing to a shine. | Ra < 0.4 $\mu m$. Low friction. Necessary for sealing surfaces or aesthetic consumer goods. | Labor Intensive. Hand-polished. Very expensive. It also rounds off sharp edges slightly. | $$$$ |

| Brushing | Unidirectional satin lines. | Aesthetic surface finish often seen on consumer electronics or kitchen appliances. | Hard to do on complex curved surfaces. Best for flat plates or cylinders. | $$ |

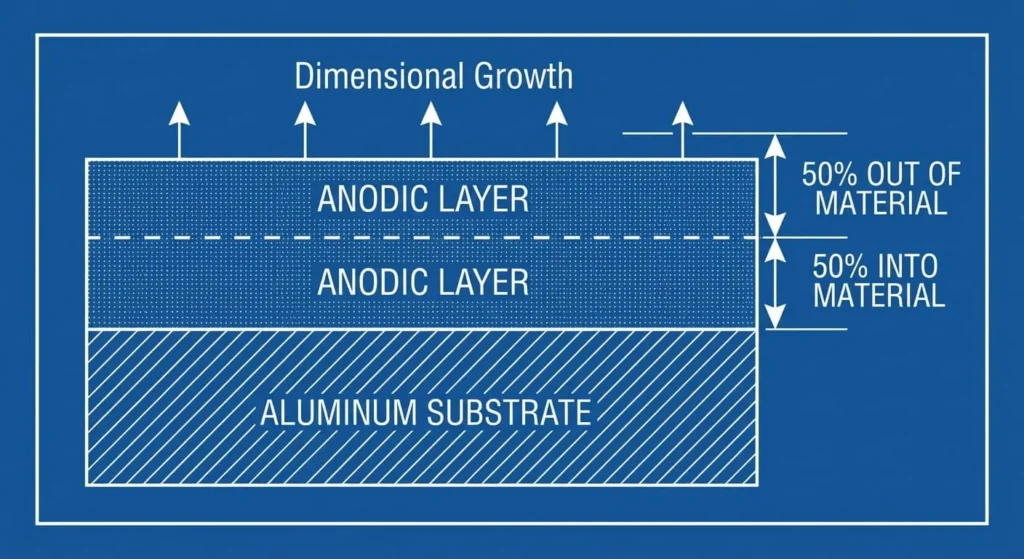

2. Anodizing (Aluminum Only): The Protective Skin

Controlled oxidation. The most popular Surface finish for Aluminum.

| Type | Name | The Design Engineer (Function) | The Shop Floor Manager (Tolerance Trap) | Best For |

| Type II | Standard / Decorative | Corrosion Resistance. Available in Black, Blue, Red, Gold, etc. Non-conductive. | Thickness: Adds ~5-10 $\mu m$ per side. Usually negligible for standard fits, but affects press-fits. Color consistency can vary between batches. | Drone parts, camera gear, brackets. |

| Type III | Hard Anodize | Wear Resistance. Extremely hard (60-70 HRC equivalent). Dark grey/black only. | Thickness: Adds 25-50 $\mu m$ (0.025-0.05mm). CRITICAL: You must account for this growth in your CAD, or the parts won’t fit. | Sliding rails, gears, military equipment. |

| Chem Film | Alodine / Chromate | Conductive. Provides mild corrosion resistance while maintaining electrical conductivity. Gold or Clear color. | Zero Growth. The coating is microscopic. Perfect for grounding points or tight tolerance mating surfaces. | Grounding plates, EMI shielding, avionics. |

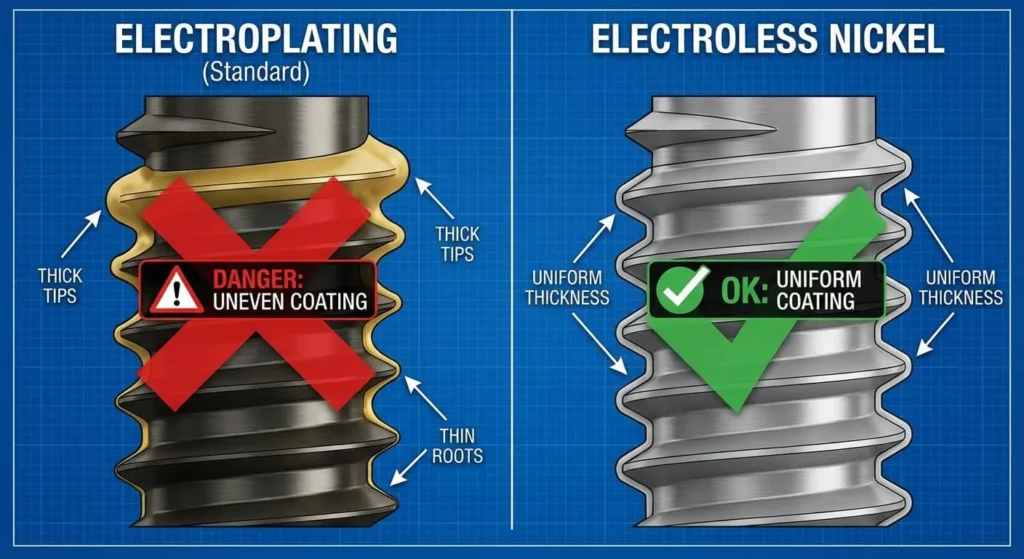

3. Plating & Chemical Conversions: The Armor

Adding a layer of another metal. Crucial for Steel and Copper.

| Surface Finish | Material | The Design Engineer (Function) | The Shop Floor Manager (Reality) | Best For |

| Zinc Plating | Steel | Sacrificial protection against rust. Usually clear (silver) or yellow. Cheap. | Not cosmetic. The Surface finish is functional and can look slightly iridescent. Good for hidden structural steel. | Brackets, fasteners, mounting plates. |

| Electroless Nickel | Steel / Alum | Uniformity. Unlike electroplating, this covers every nook and internal thread evenly. Hard and lubricious. | The Precision Choice. Because it’s “electroless,” it doesn’t build up on corners (dog-boning). We love this for complex geometries. | Gears, internal valve components, shafts. |

| Passivation | Stainless Steel | Cleaning. Removes free iron from the surface using acid. Restores corrosion resistance. | Invisible. It doesn’t change the look or dimensions. It just ensures your stainless steel stays stainless. | Medical devices, food processing parts. |

| Black Oxide | Steel | Mild corrosion resistance. Reduces light reflection. | Zero Growth. It’s a chemical conversion, not a plating. It absorbs oil to prevent rust. | Tooling, firearm components, optical rigs. |

4. Paintings & Coatings: The Heavy Duty

Thick layers for extreme aesthetics or durability.

| Type | The Design Engineer (Function) | The Shop Floor Manager (The Masking Headache) |

| Powder Coat | Durability. A baked-on plastic powder. Extremely tough, UV resistant, hides surface defects. | Thick! Adds 60-100 $\mu m$. It will clog threads and holes. Masking is expensive: We have to plug every hole manually before coating. |

| Wet Paint | Aesthetics. High gloss, metallic flakes, specific RAL color matching (branding). | Delicate. Easier to scratch than powder coat. Requires a primer. Best for show-quality cosmetic parts. |

Summary: The “Surface Selection Matrix”

How do you decide? Follow this flow:

- Is it Aluminum?

- Need color? ➡Anodize Type II.

- Need wear resistance?➡ Anodize Type III.

- Need conductivity? ➡ Chem Film (Alodine).

- Is it Steel?

- Cheap rust protection?➡ Zinc Plating.

- Precision fit + Hardness? ➡ Electroless Nickel.

- Medical/Food? ➡ Passivation.

- Is it Cosmetic?

- Matte look? ➡ Bead Blast + Anodize.

- Shiny? ➡ Polishing.

⚠️ The Expert’s Final Warning: “Design for Masking”

“The most expensive part of finishing isn’t the chemical; it’s the labor. If you ask for ‘Powder Coat everything EXCEPT this one tiny complex surface,’ we have to apply high-temperature tape by hand under a microscope.

Money Saving Tip: If possible, design the part so the entire surface can be treated, or use a chemical conversion (like Alodine or Black Oxide) that doesn’t need masking for tolerance.”

Start Your Project with the Right surface Finish

Don’t let a bad surface finish ruin a precision part. At CNMP, we inspect every finish for adhesion, thickness, and aesthetic defects.

- Need a specific look? Check our Surface Finish Gallery.

- Worried about tolerances? Upload your drawing to our Quote Engine, and our engineers will flag potential coating issues before we cut metal.