About CNMP – Precision CNC Machining Partner You Can Trust

CNMP is a professional CNC machining manufacturer in China, specializing in precision milling, turning, 5-axis machining, prototyping, and surface finishing. With ISO 9001 and IATF 16949 certifications, advanced equipment, and a highly skilled engineering team, we provide quality-assured components to clients across automotive, medical, aerospace, laboratory, sanitary, and hydraulic industries.

Our Story – From Precision to Partnership

At CNMP, precision is not just a manufacturing goal — it’s our foundation.

Established in China with a vision to bring world-class CNC machining to global industries, CNMP has evolved from a dedicated machining workshop into a trusted international supplier of precision components for automotive, medical, aerospace, laboratory, sanitary, and hydraulic sectors.

Our journey began with a single belief: that reliable quality and transparent communication can bridge global manufacturing gaps.

From our first exported component to today’s multi-industry partnerships, every project has been guided by the same principle — precision, consistency, and trust.

Over the years, CNMP has steadily expanded its production capabilities and quality control systems to meet the increasingly complex demands of global clients. Today, our facility houses:

50 CNC turning centers for high-precision cylindrical components

30 CNC milling machines for complex geometries and multi-surface parts

5 advanced 5-axis machining centers for complex prototypes and tight-tolerance applications

4 mid-sized 4-axis machining centers for medium-complexity parts

3 stable 3-axis machining centers for high-efficiency production

These investments, combined with ISO 9001 and IATF 16949 certifications, ensure every component we deliver meets international standards for accuracy, traceability, and reliability.

We don’t just make parts — we manufacture confidence.

But what truly sets CNMP apart is our engineering-driven approach.

Our team doesn’t simply follow drawings; we study them.

Before production, our engineers provide Design for Manufacturability (DFM) insights to optimize part geometry, improve cost-efficiency, and minimize production risks. This collaborative process helps clients — from prototype innovators to OEM manufacturers — bring their designs to life faster, with fewer iterations and better performance.

CNMP’s vision is to be the most dependable CNC machining partner for global engineers — a company that speaks the same technical language, meets deadlines without compromise, and stands behind every shipment with measurable quality.

As we continue to expand our global footprint, we remain guided by our founding values:

Precision in every detail. Transparency in every process. Partnership in every project.

Our Capabilities

CNMP provides a full suite of precision CNC services designed for reliability, repeatability, and fast turnaround. Below are our core capabilities and the applications they support.

CNC Turning Services

High-precision CNC turning performed on our production lathes for shafts, bushings, threaded parts and complex turned geometries. Ideal for both rapid prototypes and high-volume runs where consistency and surface finish matter. We support multistage turning, live tooling operations and secondary machining.

CNC Milling Services

Comprehensive milling capability for pockets, bores, contours and multi-surface components. Our milling fleet includes 30 milling centers (including multi-axis machines) that handle everything from simple prismatic parts to complex, tight-tolerance components for automotive, medical and industrial applications.

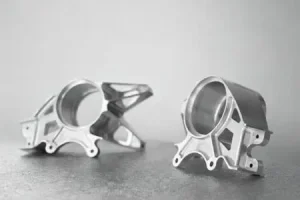

5-Axis CNC Machining

Five high-precision 5-axis centers enable single-setup machining of complex shapes, multi-face parts and freeform surfaces—reducing setups, improving accuracy and lowering cycle time. Common uses: impellers, aerospace fittings, medical components and precision fixtures.

CNC Prototyping Services

Fast-turn prototyping and low-volume manufacturing with active DFM feedback. We offer quick sampling, iterative prototyping cycles, and small-batch production to accelerate product development while validating manufacturability and assembly fit.

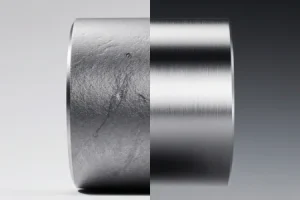

Surface Treatment

Complete surface finishing options to meet functional and aesthetic requirements: anodizing, passivation, electroless plating, electroplating (nickel/zinc), black oxide, powder coating, bead blasting, and heat treatment. Finishes are performed in-house or via qualified partners with full traceability.

Material Capability

We machine a wide range of metals and engineering plastics, including but not limited to: aluminum alloys, stainless steels, carbon steels, brass, copper, titanium, POM, Nylon and PTFE. Material sourcing, mill certificates and material traceability are available upon request.

Quality Assurance – Precision You Can Measure

At CNMP, quality is built into every process — not inspected at the end.

Our goal is to ensure that every component leaving our factory meets the exact specifications, tolerances, and performance standards required by our clients across automotive, aerospace, medical, laboratory, and industrial sectors.

We operate under a strict quality management system certified to ISO 9001 and IATF 16949, ensuring full traceability, documented procedures, and consistent process control throughout production.

Material Inspection

All raw materials are checked for compliance with specifications and accompanied by mill certificates. Materials are traceable throughout the entire production chain.

In-Process Inspection

During machining, our operators perform regular checks using calibrated gauges, micrometers, and projectors. Critical dimensions are monitored at each production stage to prevent deviation and ensure stability in mass production.

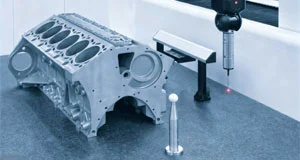

Final Inspection

Before shipment, every part passes through a comprehensive quality check conducted by our dedicated QC engineers using advanced instruments including CMM (Coordinate Measuring Machine), 2.5D projectors, surface roughness testers, and hardness testers.

Inspection reports, PPAP documents, or measurement data can be provided upon request.

Packaging & Verification

Products are cleaned, protected, and packed according to client requirements. Each lot is labeled with inspection data and traceability codes to ensure easy reference.

Industries We Serve

At CNMP, our machining expertise extends across a wide range of industries, each with unique material, tolerance, and certification demands.

By understanding the specific challenges of every sector, we provide precision-engineered solutions that meet strict performance, safety, and compliance requirements.

Automotive Components

CNMP serves Tier-1 and Tier-2 automotive suppliers with high-precision components used in engine systems, transmission assemblies, and chassis parts.

Our IATF 16949-certified quality system ensures consistent production and full traceability.

We specialize in complex geometries, tight tolerances, and heat-treated materials commonly used in vehicle dynamics systems.

High-volume CNC turning & milling

Tight tolerance ±0.005mm components

Surface finishing and corrosion resistance

Material traceability and PPAP documentation

Medical & Laboratory Equipment

For the medical and laboratory sectors, precision and cleanliness are paramount.

CNMP produces parts for analytical instruments, surgical equipment, and laboratory testing systems where accuracy, consistency, and biocompatibility are essential.

Key Capabilities:

Machining of stainless steel, titanium, and aluminum alloys

Cleanroom-ready finishing and packaging

Surface polishing and passivation

Low-volume prototyping for new device development

Aerospace & Defense

The aerospace industry demands unmatched precision and compliance.

CNMP delivers machined components for structural assemblies, testing fixtures, and high-performance mechanical systems.

Our engineers follow strict tolerance standards and documentation control to meet aerospace-grade requirements.

Key Capabilities:

5-axis CNC machining for complex geometries

Lightweight aluminum and titanium parts

Strict dimensional verification using CMM

AS9100-compliant documentation on request

Hydraulic & Energy Systems

In hydraulic and energy systems, performance reliability under pressure is vital.

CNMP supplies valve housings, pump bodies, and fluid control components with optimized internal channels and sealing surfaces for maximum durability and efficiency.

Key Capabilities:

Deep-hole drilling and precision threading

Machining of stainless steel and copper alloys

High-pressure testing and sealing verification

Custom surface treatments for corrosion protection

Sanitary & Industrial Hardware

From stainless steel bathroom fittings to precision connectors, CNMP provides durable and aesthetically refined components that combine functionality and appearance.

We understand the requirements for consistent surface finishing, dimensional accuracy, and long-term durability.

Key Capabilities:

CNC machining for stainless and brass components

Mirror polishing and surface coating

Batch consistency for high-end hardware series

Fast delivery for OEM/ODM projects

Why Industry Diversity Matters

Our experience across multiple industries allows CNMP to apply cross-sector best practices —

from aerospace precision to automotive efficiency, from medical-grade finishing to consumer durability.

This synergy results in smarter manufacturing solutions, reduced lead time, and greater reliability for every client.

Our Team & Engineering Support

At CNMP, our strength lies not only in our advanced CNC equipment, but in the people behind the machines — our engineering and project teams who ensure every component meets your exact specifications.

Our engineers combine years of hands-on manufacturing experience with a deep understanding of mechanical design, materials, and tolerances.

From DFM (Design for Manufacturability) consulting to prototype validation and production optimization, our technical team works closely with clients to reduce costs, minimize lead time, and achieve higher precision.

⚙️ Engineering Expertise

Every project at CNMP begins with engineering insight.

Before machining starts, our engineers review 3D models and technical drawings to identify potential issues in geometry, tolerance stack-up, or material selection.

This proactive approach helps prevent costly design iterations and accelerates product launch.

Our engineering support includes:

DFM & DFA analysis

Material recommendation (metal & polymer)

Process route design (turning / milling / 5-axis)

Fixture & tool path optimization

Dimensional inspection and verification reports

👥 Project Management & Communication

We understand that effective communication is key to successful projects — especially in international cooperation.

Our English-speaking project managers and engineers are trained to understand technical terminology, standards, and client expectations.

Each client is assigned a dedicated project contact, ensuring clear updates and efficient coordination from quotation to shipment.

What clients appreciate most:

Fast response to technical queries

Regular progress reports with photos/videos

Multi-language communication (English, Chinese)

Commitment to on-time delivery

🧩 Prototyping to Production

CNMP offers rapid prototyping and low-volume production with the same attention to detail as mass production.

We provide functional prototypes for performance testing and pre-production validation.

Once approved, our production team ensures seamless scale-up with repeatable precision.

Key advantages:

Quick prototype turnaround

Consistent process documentation

Tight tolerance control across batches

Transparent communication during development

🌐 Collaboration Tools

We use industry-standard tools and software to enhance engineering collaboration:

CAD/CAM integration (SolidWorks, UG, MasterCAM)

Secure drawing and data handling (NDA-compliant)

Online file sharing and progress tracking

Inspection reports with digital traceability

Advanced Equipment

Precision starts with technology. CNMP operates advanced CNC machining centers, inspection systems, and automated tools

that ensure consistent accuracy from prototype to mass production.

5-Axis Machining Centers

High-speed 5-axis CNC machines enable complex geometries and multi-surface machining with micron-level precision.

CNC Turning & Milling Centers

Equipped with multi-axis lathes and vertical/horizontal mills for efficient, high-volume precision part production.

CMM Inspection Systems

Coordinate Measuring Machines (CMM) and optical inspection tools verify dimensional accuracy for critical components.

Automated Tool Calibration

Automated measurement and calibration systems ensure tool accuracy and reduce machine downtime.

Surface Finishing & Treatment

In-house polishing, anodizing, sandblasting, and coating deliver both performance and aesthetic perfection.

Material Testing Laboratory

Advanced material and hardness testing equipment ensure raw materials meet strength and consistency standards.

Global Clients & Case Studies

CNMP partners with international clients across diverse industries, providing precision machining solutions that meet global standards for quality, documentation, and delivery.

Our Partners

Our Case

*All the photos and texts published on the website have obtained the necessary authorization permission.

Certifications & Compliance

CNMP operates under globally recognized quality management systems and manufacturing standards.

From raw material traceability to environmental compliance, every step is verified to meet the requirements of our international partners.

ISO 9001:2015

Certified for quality management and process consistency, ensuring reliable production and continuous improvement across all operations.

IATF 16949

Automotive-grade certification covering design, manufacturing, and quality control for high-precision mechanical components.

RoHS & REACH Compliance

All materials and surface treatments meet EU environmental and safety standards, with full documentation available on request.

Material Traceability

From raw stock to finished part, all materials are tracked with lot codes and inspection reports to guarantee transparency and accountability.

CMM & Inspection Reports

Dimensional inspection reports, FAI (First Article Inspection), and full CMM data can be provided with every order.

Sustainable Manufacturing

CNMP continuously invests in eco-friendly equipment and waste management systems to support sustainable, low-impact production.

CNMP is committed to maintaining the highest levels of quality, compliance, and environmental responsibility.

Ready to Start Your CNC Machining Project?

Share your requirements or upload your drawings — our engineers will respond with technical feedback and a detailed quotation within 24 hours.

Email:info@cnmachiningparts.com

Whatsapp/Tel/Wechat:+86 18870025173

*We are online 24 hours a day.