CNC Surface Finishing Services

Enhancing Durability, Performance, and Aesthetics of Precision Machined Parts

At CNMP, we provide a wide range of CNC surface finishing services to improve the strength, appearance, and functionality of your parts. From anodizing and plating to polishing and powder coating, our finishing solutions ensure that your components meet the highest standards of performance and design.

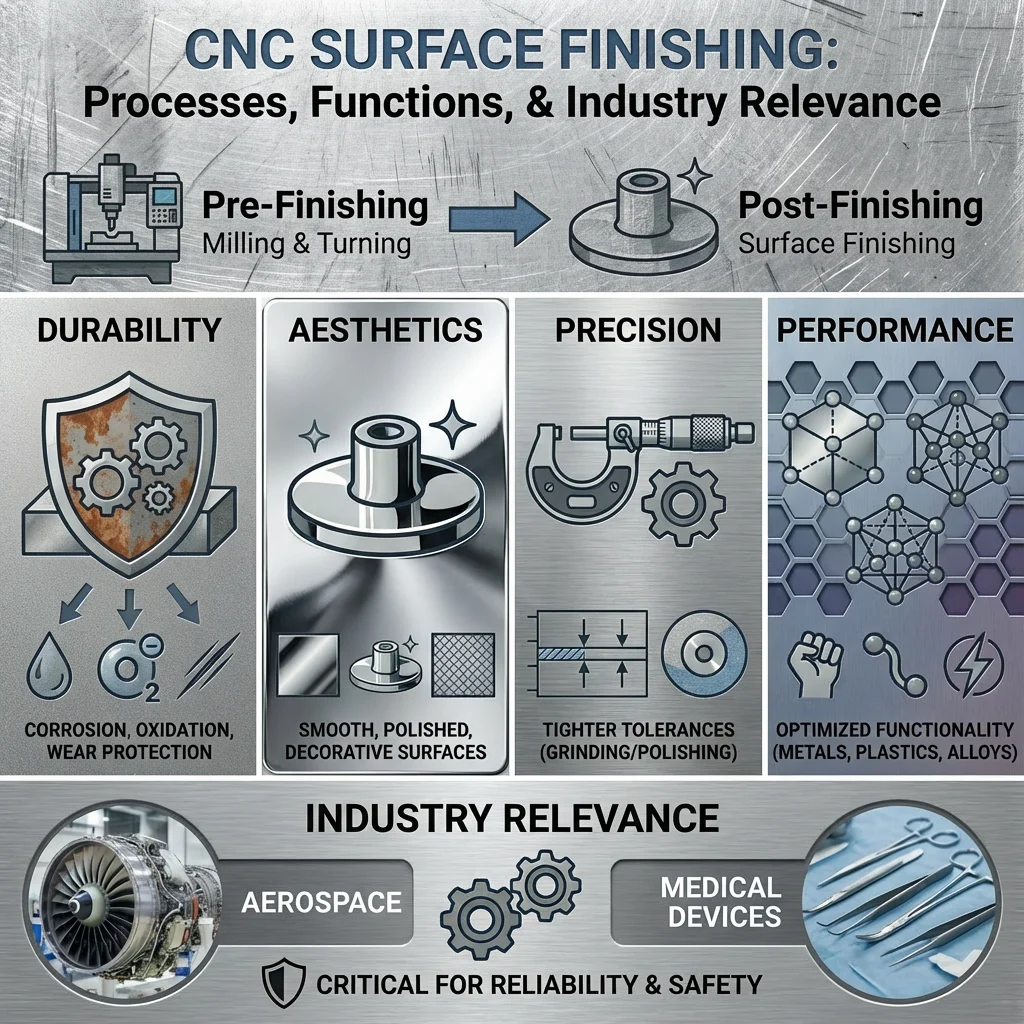

What is CNC Surface Finishing?

CNC surface finishing refers to the range of processes applied to machined parts after precision CNC milling or turning. These processes are designed to improve surface quality, durability, and appearance. Depending on the material and the end-use, finishing can enhance corrosion resistance, achieve tighter tolerances, or provide a specific aesthetic effect.

Key Functions of CNC Surface Finishing:

Improved Durability – Protects against corrosion, oxidation, and wear.

Enhanced Aesthetics – Delivers smooth, polished, or decorative appearances.

Dimensional Precision – Achieves tighter tolerances through grinding or polishing.

Material-Specific Performance – Optimizes functionality for metals, plastics, and alloys.

Industry Relevance:

From aerospace to medical devices, high-performance industries rely on CNC finishing to meet strict standards for reliability, safety, and performance.

CNMP’s Surface Finishing Capabilities

At CNMP, surface finishing is more than just an additional step — it is a critical stage that ensures every CNC machined component meets functional and aesthetic requirements. Our finishing capabilities cover a wide range of methods tailored for metals, plastics, and advanced alloys, allowing us to serve industries where quality and reliability cannot be compromised.

Anodizing & Hard Anodizing

Ideal for aluminum components, anodizing improves corrosion resistance, surface hardness, and color options for aesthetic appeal.

Powder Coating & Painting

Provides durable, decorative, and protective coatings for parts exposed to wear, chemicals, or outdoor environments.

Electroplating

Adds wear resistance, corrosion protection, and conductive surfaces for electronic and mechanical applications.

Polishing & Buffing

Achieves smooth surfaces and mirror finishes, essential for medical devices, consumer electronics, and optical components.

Bead Blasting & Sandblasting

Creates uniform matte or textured finishes, improving both appearance and adhesion for coatings.

Passivation

Enhances stainless steel’s corrosion resistance without altering its appearance, widely used in aerospace and medical parts.

Finishing Comparison Table

| Process | Surface Appearance | Durability / Wear Resistance | Corrosion Resistance | Applications | Cost Level | Lead Time | Key Notes |

|---|---|---|---|---|---|---|---|

| Anodizing (Aluminum) | Matte to glossy colors, protective layer | ★★★★☆ | ★★★★☆ | Aerospace parts, electronics housings, auto | $$ | Medium | Performance depends on film thickness and sealing quality. |

| Powder Coating | Smooth, uniform, wide color options | ★★★★☆ | ★★★★☆ | Automotive, consumer products, machinery | $$ | Medium | Excellent decoration and good protection. Wear resistance is better than painting but inferior to metallic coatings. |

| Polishing / Buffing | Mirror-like reflective finish | ★★☆☆☆ | ★★☆☆☆ | Medical instruments, decorative parts | $$ | Slow | Primarily decorative. Does not enhance corrosion resistance and can even trap contaminants. |

| Bead Blasting | Matte, satin, non-reflective | ★★☆☆☆ | ★★☆☆☆ | Tooling, prototypes, aerospace interiors | $ | Fast | Used for aesthetic finishing and surface cleaning. Does not improve material properties. |

| Electroplating (Ni, Cr, Zn) | Bright metallic, decorative or functional | ★★★★☆ | ★★★★☆ | Automotive, connectors, hardware | $$ | Medium | Ratings are generalized. Performance varies significantly by plating type (e.g., Hard Chromium has excellent wear resistance). |

| Passivation (Stainless Steel) | Invisible, cleans & protects surface | ★☆☆☆☆ | ★★★★☆ | Medical implants, aerospace, food industry | $ | Fast | A chemical process that does not add thickness. It enhances stainless steel’s inherent corrosion resistance but provides no improvement in wear resistance. |

| Black Oxide | Matte black, non-reflective | ★★☆☆☆ | ★☆☆☆☆ | Firearms, tools, machine components | $ | Fast | The coating is very thin. Requires a post-treatment oil seal or wax to provide any meaningful corrosion resistance. |

| Painting | Flexible colors, can add branding/logos | ★★★☆☆ | ★★★☆☆ | Prototypes, consumer electronics, housings | $$ | Fast | Performance depends on the paint type (e.g., epoxy, polyurethane) and film thickness. |

| Hard Anodizing | Dark gray/black, thicker protective layer | ★★★★★ | ★★★★☆ | Aerospace turbine, automotive pistons, gears | $$ | Medium | Offers an extremely hard and wear-resistant surface, which is one of its primary advantages. |

| PVD Coating (TiN, DLC) | Metallic colors (gold, black, rainbow) | ★★★★★ | ★★★★★ | Cutting tools, medical implants, watches | $$$ | Slow | A top-tier, high-performance coating offering superior hardness and excellent corrosion resistance. Higher cost. |

Industries We Served

CNC surface finishing plays a critical role across industries where both function and appearance matter. Different sectors require unique finishing standards — from corrosion resistance to biocompatibility — and understanding these requirements ensures better decision-making for engineers and procurement teams.

Aerospace

Why it matters: Aerospace parts such as turbine blades and structural components demand coatings that withstand extreme temperatures, friction, and corrosion.

Key concerns: Surface treatments like anodizing and passivation must meet strict aerospace compliance.

Relevant finishes: Hard anodizing, passivation, precision polishing.

Keywords embedded: aerospace finishing, CNC aerospace parts, anodized aerospace components.

Automotive

Why it matters: Automotive prototype molds, engine components, and lightweight structures require durability and corrosion resistance under daily wear.

Key concerns: Cost efficiency and consistency across large batches.

Relevant finishes: Powder coating, anodizing, black oxide.

Keywords embedded: automotive CNC finishing, powder-coated automotive parts, CNC machined car components.

Medical Devices

Why it matters: Implants and surgical instruments must ensure biocompatibility and absolute cleanliness.

Key concerns: Customers care about sterility, smooth surfaces to avoid bacterial growth, and regulatory compliance.

Relevant finishes: Electropolishing, passivation, fine polishing.

Keywords embedded: CNC medical finishing, surgical instrument polishing, biocompatible finishing.

Industrial Equipment & Energy

Why it matters: Device housings, connectors, and internal components rely heavily on surface aesthetics as well as corrosion protection.

Key concerns: Consistency in appearance, scratch resistance, and premium look.

Relevant finishes: Bead blasting, anodizing, painting.

Keywords embedded: CNC finishing for electronics, anodized aluminum housings, electronic CNC parts.

hydraulic engineering

Why it matters: Valves, turbines, and fluid-handling components require finishes that improve lifespan under high-pressure or corrosive environments.

Key concerns: Wear resistance, anti-corrosion, and cost-effective solutions for heavy-duty equipment.

Relevant finishes: Zinc plating, passivation, specialized coatings.

Keywords embedded: CNC finishing for industrial equipment, corrosion-resistant finishes, CNC machined energy parts.

Surface Finishing Gallery

A curated showcase of CNC machined parts after applying different surface finishes. This gallery helps visitors visually compare outcomes and understand which finish best fits their industry requirements.

Anodizing

Creates a protective oxide layer while allowing vivid colors like blue, red, gold, and black.

Ideal for: aerospace, electronics housings, and decorative components.

Polishing

Achieves a smooth, reflective surface with high aesthetic appeal.

Ideal for: medical tools, luxury automotive components, and consumer electronics.

Bead Blasting

Produces a uniform matte surface with a subtle texture that reduces glare.

Ideal for: automotive prototypes, aerospace brackets, and mechanical housings.

Black Oxide

Adds mild corrosion resistance and a dark black appearance.

Ideal for: tool steel parts, mechanical shafts, and gears

Powder Coating

Applies a thick, durable colored layer for wear and corrosion protection.

Ideal for: outdoor equipment, automotive components, and enclosures.

Brushed Metal

Creates linear grain patterns for a technical, industrial look.

Ideal for: consumer electronics, decorative panels, and appliances.

Why Choose Us for CNC Surface Finishing?

Surface finishing is more than just aesthetics—it determines durability, performance, and how parts interact with their environment. CNMP ensures every finishing process is carried out with precision, consistency, and industry expertise.

CMM verification • Batch color matching • RoHS / REACH support

Comprehensive Finishing Options

From anodizing and hard-anodize to PVD, electroplating, powder coating, polishing and bead blasting — we offer end-to-end finishing services for metals and plastics.

Anodizing • PVD • Powder Coat

Quality & Consistency

We apply strict process controls, color matching, and batch inspections to ensure uniform finishes across every production run.

CMM checks • Batch Color Match

Industry-Grade Standards

Our finishes meet the regulatory and performance criteria required by aerospace, medical, and automotive customers.

Aerospace • Medical • Automotive

Different substrates need different treatments. We match process parameters to aluminum, stainless steel, titanium and engineering plastics for optimal results.

Al, SS, Ti, Plastics

FAQs about CNC Surface Finishing

We’ve compiled the most frequently asked questions about CNC surface finishing. This section is designed to help engineers, buyers, and project managers understand processes, tolerances, and costs without any marketing fluff.

Request a Quote for Surface Finishing

Choosing the correct finish is critical to part performance and compliance. Share your drawing and project details below — include material, required finish, tolerance, and quantity — and our engineers will review and return a tailored quote. We support prototypes and production runs and can handle NDA-protected projects.

•Fast technical review

• File-safe uploads (STEP/IGES/Parasolid/PDF)

• NDA available on request