5 Axis CNC Machining Services for Complex & Precision Parts

Unlock advanced multi-axis machining capabilities with CNMP. From aerospace components to medical devices and automotive parts, our 5-axis CNC machining ensures accuracy, efficiency, and reduced lead times.

What is 5 Axis CNC Machining?

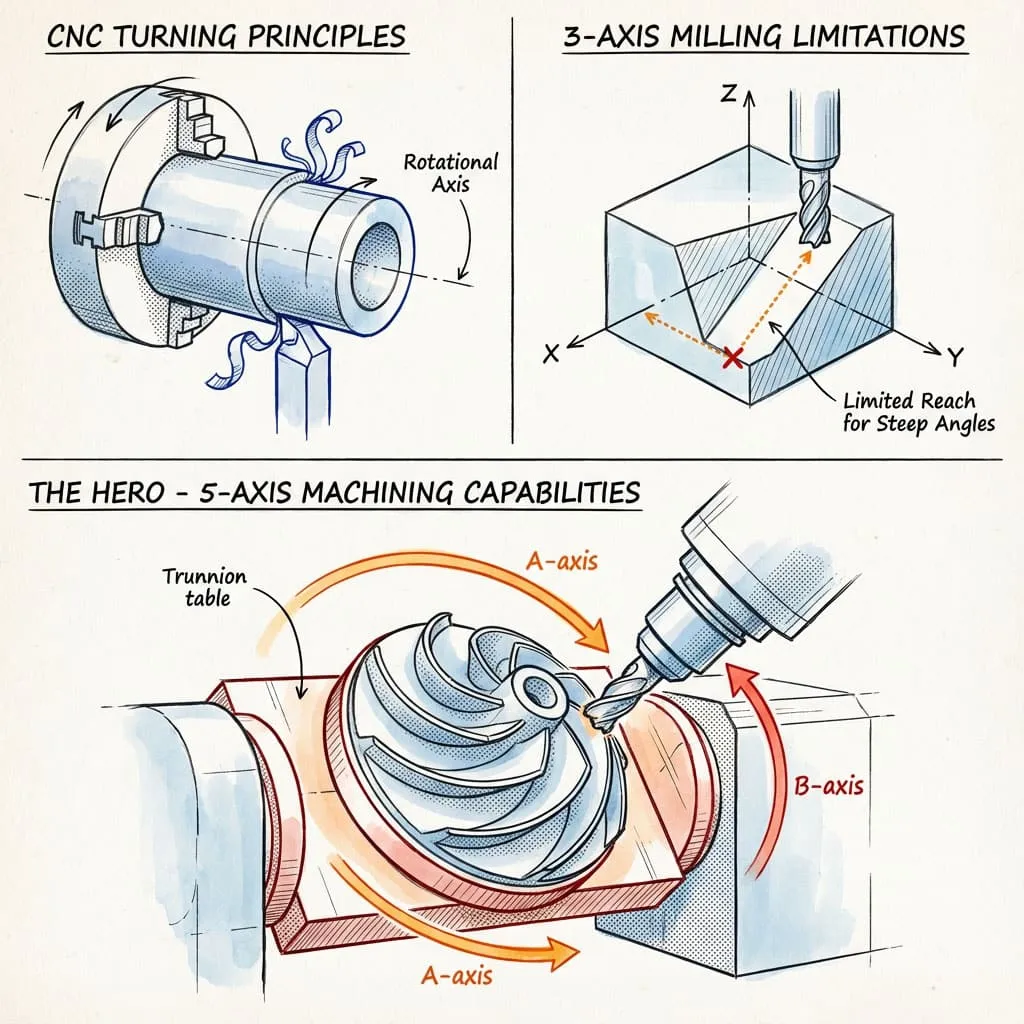

5-axis CNC machining is a process where the cutting tool or the part can move along five different axes simultaneously. Unlike traditional 3-axis machining, which only moves along X, Y, and Z, 5-axis machining adds two additional rotational movements (A and B axes). This enables the machining of complex geometries in a single setup.

Why it matters:

Reduced setups: Many features of a part can be machined without repositioning, improving accuracy.

Precision: Achieves tight tolerances required in aerospace, medical devices, and automotive parts.

Complex geometries: Ideal for turbine blades, impellers, molds, and orthopedic implants.

Surface quality: Fewer transitions between setups means smoother finishes.

Comparison:

3-Axis Machining: Suitable for basic parts, prismatic shapes.

4-Axis Machining: Adds rotation for cylindrical parts.

5-Axis Machining: Handles complex, multi-surface, high-precision parts efficiently.

CNMP’s 5 Axis CNC Machining Capabilities

Our 5-axis CNC machining services are designed for complex geometries, tight tolerances, and multi-surface precision. By combining simultaneous axis movement with advanced tooling, CNMP ensures that parts for industries like aerospace, automotive, and medical devices are manufactured with accuracy and efficiency.

Complex Geometry Machining

Our 5-axis machines excel at producing intricate parts such as turbine blades, impellers, and orthopedic implants. Multi-angle tool access reduces multiple setups, ensuring higher accuracy and shorter lead times.

Single-Setup Manufacturing

With 5-axis technology, multiple sides of a part can be machined in one setup, minimizing human error and maximizing precision.

Tight Tolerance Control

We achieve precision tolerances as tight as ±0.005 mm, ideal for medical instruments, aerospace brackets, and automotive engine parts.

Improved Surface Finishing

Continuous tool movement in 5-axis machining provides superior surface quality, often eliminating secondary finishing steps.

Wide Range of Applications

From aerospace turbine blades to medical implants and automotive prototypes, our 5-axis CNC machining supports industries requiring both complexity and reliability.

Materials We Work With

At CNMP, our 5-axis CNC machining services are optimized for a wide range of materials, from lightweight alloys to advanced engineering metals. By combining multi-angle cutting with high-precision tooling, we can achieve consistent accuracy, even on difficult-to-machine materials such as titanium and Inconel. This flexibility ensures that industries like aerospace, automotive, medical devices, and energy can rely on us for reliable, high-performance components.

Aluminum Alloys (e.g., AL-6061, AL-7075)

Why it matters: Lightweight, excellent machinability, ideal for aerospace and automotive prototypes.

Common challenge: Deformation during complex 5-axis machining.

How we solve it: Using optimized clamping and toolpath strategies to maintain dimensional accuracy.

Stainless Steel (SS 304, SS 316, SS 303)

Why it matters: High strength and corrosion resistance, widely used in marine, food processing, and medical devices.

Common challenge: Tool wear and heat generation.

How we solve it: Advanced coolant systems and multi-angle tool access to reduce cycle time.

Titanium Alloys (Ti-6Al-4V)

Why it matters: Exceptional strength-to-weight ratio, critical for aerospace and medical implants.

Common challenge: Hardness makes machining slow and tool-intensive.

How we solve it: 5-axis movement reduces re-clamping, improving efficiency and preserving precision.

Engineering Plastics (POM, PEEK, Nylon)

Why it matters: Lightweight, versatile, suitable for prototypes and functional components.

Common challenge: Dimensional stability during high-speed machining.

How we solve it: Precision clamping and low-heat cutting methods to avoid warping.

Copper and Brass

Why it matters: Excellent electrical and thermal conductivity, key for electronics and energy industries.

Common challenge: Maintaining surface finish without burrs.

How we solve it: Fine toolpath strategies and controlled feed rates for high-quality finishes.

Industries Served

Our 5-axis CNC machining services are trusted across industries where precision, efficiency, and complex geometries are critical. By eliminating multiple setups and enabling multi-angle machining, CNMP provides solutions that meet the demanding requirements of aerospace, medical, automotive, energy, and research applications.

Aerospace

Applications: Turbine blades, impellers, structural airframe components.

Why 5-axis matters: Achieves precise aerodynamic shapes with reduced setup time and unmatched accuracy.

Medical

Applications: Orthopedic implants, dental components, surgical instruments.

Why 5-axis matters: Enables complex organic geometries and smooth surface finishes critical for biocompatibility.

Automotive

Applications: Prototype mold parts, lightweight aluminum brackets, structural components.

Why 5-axis matters: Fast prototyping and production of complex geometries for next-gen automotive designs.

Energy

Applications: Turbomachinery components, fluid handling parts, high-strength housings.

Why 5-axis matters: Efficiently machines heat-resistant alloys like Inconel and titanium for demanding energy systems.

Research & Laboratories

Applications: Complex prototypes, experimental parts, precision test fixtures.

Why 5-axis matters: Flexibility to manufacture one-off or small-batch components for R&D with extreme precision.

5-Axis Machining Part Gallery

Our 5-axis CNC machining part gallery showcases components manufactured for industries that demand tight tolerances, complex geometries, and high-quality finishes. From aerospace turbine blades to custom medical implants, each part demonstrates CNMP’s ability to meet the most challenging machining requirements.

Aerospace Components

Examples: Turbine blades, impellers, structural parts.

Key Value: High aerodynamic precision, lightweight design, and surface consistency.

Medical Components

Examples: Titanium bone plates, dental implants, surgical tools.

Key Value: Smooth biocompatible finishes and complex organic shapes.

Automotive Parts

Examples: Prototyping molds, lightweight brackets, engine components.

Key Value: Fast turnaround for prototypes and accurate machining of complex structures.

Energy Sector Parts

Examples: Turbomachinery housings, fluid handling parts, heat-resistant alloy components.

Key Value: Reliable machining of Inconel and titanium for high-performance energy systems.

Research & Custom Prototypes

Examples: Experimental fixtures, custom small-batch parts.

Key Value: Flexibility for one-off and R&D projects requiring precision and adaptability.

Why Choose Us for 5-Axis CNC Machining?

When selecting a partner for 5-axis CNC machining services, customers often face questions about precision, material capability, turnaround, and cost efficiency. At CNMP, we address these concerns directly to ensure reliable, high-quality results.

Advanced Precision

Our 5-axis machining centers achieve tight tolerances and consistent accuracy, even for highly complex parts such as aerospace turbine blades or medical implants.

Benefit: Clients avoid costly redesigns caused by dimensional deviations.

Wide Material Expertise

From aluminum and stainless steel to titanium alloys and Inconel, our expertise covers the full spectrum of engineering materials.

Benefit: Customers can develop parts without worrying about material limitations.

Faster Prototyping & Production

Simultaneous 5-axis machining reduces setups, shortens cycle times, and improves surface finishes.

Benefit: Accelerates prototype validation and scales smoothly into production.

Industry-Specific Experience

Serving aerospace, automotive, medical, energy, and research labs, we understand each sector’s standards and certification needs.

Benefit: Clients receive not only parts, but also compliance with industry-specific requirements.

Commitment to Quality Assurance

Every part undergoes CMM inspection, surface finishing checks, and tolerance verification.

Benefit: Customers gain confidence that every component meets specification before delivery.

FAQs about 5-Axis CNC Machining

Request a Quote for 5-Axis CNC Machining

Need Precision for Complex Parts?

Our team specializes in 5-axis CNC machining services for industries such as aerospace, medical, automotive, energy, and research labs. If you need turbine blades, titanium implants, lightweight prototypes, or precision structural components, we can help.

Fill out the form, and our engineers will review your requirements and provide a tailored quote.

✅ Fast response within 24 hours

✅ Support for prototypes and production runs

✅ High-precision tolerance up to ±0.005mm