CNC Turning Services

Our CNC turning services deliver accurate and consistent turned parts for industries such as automotive, aerospace, electronics, and medical devices. With advanced CNC lathes and Swiss turning machines, we manufacture shafts, bushings, fasteners, and custom cylindrical components with tight tolerances and smooth finishes.

What is CNC Turning?

CNC turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical parts. Unlike CNC milling, where the cutting tool rotates, in CNC turning the workpiece itself rotates while the cutting tool moves along defined paths.

This process is commonly carried out on CNC lathes or Swiss-type turning machines, making it ideal for producing shafts, bushings, fasteners, and threaded components with consistent accuracy.

Why CNC Turning Matters?

Efficiency: CNC turning is well-suited for round or symmetrical parts, enabling faster cycle times.

Precision: With tolerances often down to ±0.01 mm, it ensures the required dimensional accuracy.

Versatility: Supports different materials such as aluminum, stainless steel, brass, and titanium alloys.

Scalability: From one-off prototypes to high-volume production of CNC turned parts.

Common Applications

- Automotive: Shafts, bushings, gear blanks.

- Aerospace: Titanium fasteners, lightweight structural parts.

- Electronics: Precision connectors, micro shafts.

- Medical: Surgical instruments, orthopedic implants.

Visitor Concerns Answered

What’s the difference between CNC turning and CNC milling?

Turning is best for cylindrical parts, while milling handles more complex geometries.Can CNC turning handle both prototypes and production?

Yes — CNC turning services are flexible for small-batch R&D as well as mass manufacturing.What tolerances can be achieved?

Typically ±0.01 mm, depending on material and geometry.

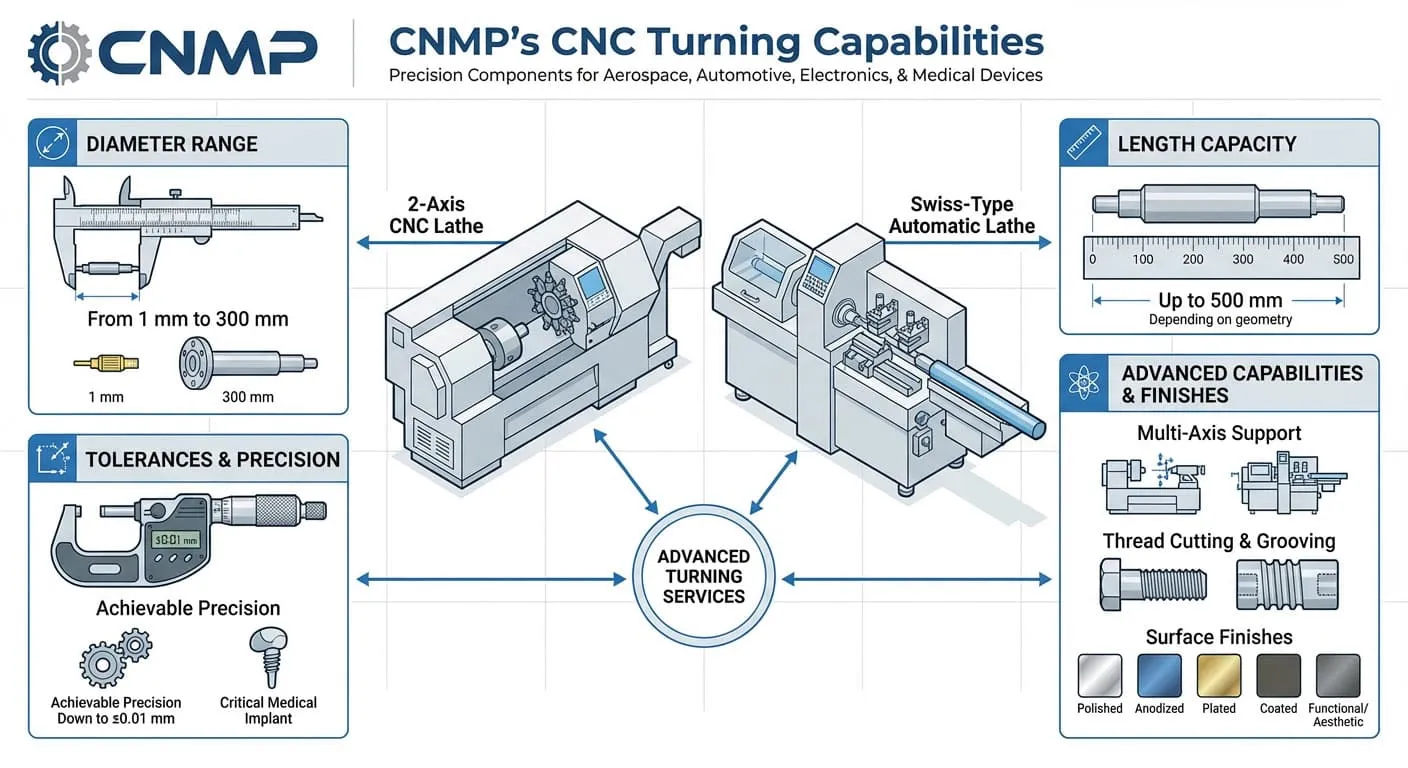

CNMP’s CNC Turning Capabilities

At CNMP, our CNC turning services combine advanced CNC lathes and Swiss turning machines to deliver precision components across industries such as aerospace, automotive, electronics, and medical devices.

Our Key Turning Capabilities

Diameter range: From 1 mm to 300 mm, suitable for both micro connectors and large shafts.

Length capacity: Up to 500 mm, depending on geometry.

Tolerances: Achievable precision down to ±0.01 mm, ensuring consistency in critical applications.

Multi-axis support: From 2-axis CNC lathes to Swiss-type automatic lathes for complex geometries.

Thread cutting & grooving: Internal and external threads, precision grooves, and custom profiles.

Surface finishes: Polished, anodized, plated, or coated for functional and aesthetic requirements.

Materials We Work With

In CNC turning services, selecting the right material is critical for achieving both precision and cost efficiency. At CNMP, we work with a wide range of metals and plastics that suit the requirements of industries such as aerospace, automotive, electronics, and medical device manufacturing. Each material presents unique machining challenges, and our experience ensures consistent quality in every CNC turned part.

Stainless Steel

- Why it matters: Offers durability and corrosion resistance; common in medical devices and marine components.

- CNC turning challenge: Hardness increases tool wear; requires optimized cutting speeds.

- Applications: Shafts, surgical tools, precision fasteners.

Aluminium

Why it matters: Lightweight and strong; widely used in automotive and aerospace.

CNC turning challenge: Maintaining surface finish during high-speed turning.

Applications: Housings, connectors, lightweight structural parts.

Brass & Copper

- Why it matters: Excellent electrical conductivity; ideal for electronics and communication.

- CNC turning challenge: Softness can lead to burrs; requires precise tooling.

- Applications: Electronic connectors, fittings, valve components.

Carbon Steel

- Why it matters: The price is relatively low and the strength is good. It’s the most common material for CNC turning services.

- CNC turning challenge: High hardness causes heat buildup; requires advanced tooling.

- Applications: Aircraft fasteners, orthopedic implants, high-performance automotive parts.

Titanium Alloys

- Why it matters: Exceptional strength-to-weight ratio; critical in aerospace and medical implants.

- CNC turning challenge: High hardness causes heat buildup; requires advanced tooling.

- Applications: Aircraft fasteners, orthopedic implants, high-performance automotive parts.

Engineering Plastics

Why it matters: Lightweight, corrosion-resistant, and cost-effective.

CNC turning challenge: Maintaining tolerance due to thermal expansion.

Applications: Bushings, insulators, fluid-handling parts.

CNC Turning Services – Industries Served

CNC turning services are widely applied across industries where precision, repeatability, and cost efficiency are critical. From aerospace components to automotive shafts and medical implants, CNC turned parts are at the core of high-performance manufacturing. Below are some of the industries where CNMP provides reliable CNC turning services.

Automotive

Why it matters: Turning is essential for manufacturing high-precision shafts, bushings, and gear components.

Key concern: Automotive customers care about tolerance control and production efficiency.

Aerospace

Why it matters: Lightweight but durable titanium and aluminium turned parts are critical for safety and performance.

Key concern: Aerospace requires tight tolerances and material traceability.

Electronics

Why it matters: Brass and copper turned connectors are widely used in consumer electronics and communication systems.

Key concern: Clients value micron-level accuracy and surface finish for small parts.

Medical & Healthcare

- Why it matters: CNC turning enables production of surgical tools, implants, and instrument components from stainless steel and titanium.

- Key concern: Medical industry demands biocompatibility and precision.

Industrial Equipment

- Why it matters: Turned components are used in pumps, valves, and machinery spindles.

- Key concern: Reliability under high load and wear resistance.

CNC Turning Part Gallery

Our CNC turning services support projects ranging from prototyping to mass production. The following gallery showcases a wide range of CNC turned parts for industries including aerospace, automotive, medical devices, electronics, and industrial equipment. Each example highlights our precision turning capabilities, typical applications, and solutions to the key concerns customers often raise about tolerance, surface finish, and consistency.

Why Choose Us for CNC Turning?

Choosing the right partner for CNC turning services is often about solving critical challenges: ensuring accuracy, meeting deadlines, and achieving cost efficiency. At CNMP, our CNC turning capabilities are designed to address these concerns for industries such as aerospace, automotive, medical devices, electronics, and industrial machinery.

Precision and Tight Tolerances

We consistently deliver CNC turned parts with tight tolerances and surface finishes that meet the requirements of aerospace fasteners, automotive shafts, and medical implants.

Material Expertise

From stainless steel (SS 304, SS 316) to aluminum alloys (6061, 7075) and titanium, we understand the machining characteristics of each material and provide solutions that optimize both performance and cost.

Consistency and Quality Assurance

With strict quality control and inspection protocols, we ensure every turned shaft, connector, and bushing meets industry-specific standards.

Flexibility for Prototypes and Production

Whether you need low-volume prototypes for design validation or high-volume production runs for automotive and electronics applications, our processes are adaptable without compromising quality.

Industry-Specific Solutions

Each industry has unique needs: aerospace demands lightweight and strong alloys, medical devices require biocompatibility, and automotive calls for durability. Our CNC turning services are aligned with these requirements.

FAQs about CNC Turning

Contact Us / Request a Quote

Get a Quote for CNC Turning Services

Looking for Precision CNC Turning?

At CNMP, we provide CNC turning services for aerospace, automotive, medical, and industrial applications. Whether you need custom CNC turned parts or high-volume production, our engineering team ensures accuracy, consistency, and efficiency.

Rapid response to RFQs (within 24 hours)

Wide material options: aluminum, stainless steel, titanium, plastics

Tolerance control for critical applications

Serving industries worldwide with reliable machining solutions

Tell us about your project, and we’ll provide a tailored solution.