Our Capabilities

From CNC turning to advanced 5-axis machining, CNMP delivers end-to-end precision manufacturing solutions. We transform complex designs into reliable parts with engineering support, surface treatment, and quality assurance.

Our CNC Machining Capabilities

Our CNC machining solutions are trusted across multiple high-precision industries. From automotive and aerospace to electronics and research labs, we provide custom machined parts that meet the rigorous standards of modern engineering and manufacturing.

CNC Turning Services

CNMP’s CNC turning department is equipped with over 50 precision lathes, capable of handling high-volume production and intricate one-off prototypes. We machine components with tight tolerances down to ±0.005mm.

CNC Milling Services

With 30 advanced milling centers and high-speed cutting tools, CNMP provides precision milling for both metals and plastics. Our engineers ensure consistent surface finish and dimensional accuracy in every part.

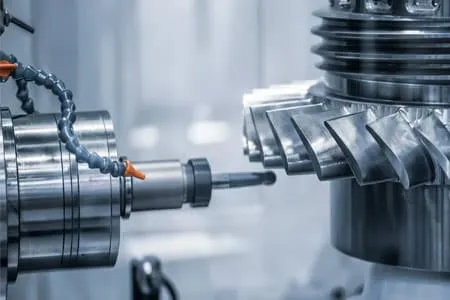

5-Axis CNC Machining

Our 5-axis CNC machines enable the production of highly complex geometries with a single setup — improving precision and reducing lead time. Ideal for aerospace, medical, and R&D applications.

CNC Prototyping Services

CNMP’s rapid prototyping solutions help clients validate designs before mass production.

Our engineering team offers DFM feedback, cost optimization, and materials consultation.

Surface Treatment

We offer a wide range of post-machining finishing processes — improving performance, durability, and appearance.

Material Expertise

CNMP works with a comprehensive range of materials — from aluminum and stainless steel to engineering plastics and exotic alloys — ensuring precision, stability, and optimal performance.

Equipment & Capability Overview

Precision, consistency, and repeatability are built into our production floor.

CNMP operates a modern facility with over 80 CNC machines, covering full machining capabilities from turning and milling to multi-axis machining.

Our in-house equipment and engineering systems ensure efficiency and accuracy for both prototyping and mass production.

CNC Prototyping Services

CNC Turning:

50 precision CNC lathes (multi-axis + automatic bar feeders)

Capable of small to medium batch production with ±0.005mm tolerance

Ideal for shafts, fittings, threaded parts, and cylindrical components

CNC Milling:

30 CNC milling centers, including 3-axis and 4-axis machines

Integrated pallet changers for continuous operation

Used for precision housings, brackets, and complex enclosures

5-Axis Machining:

5 advanced simultaneous 5-axis machining centers

Perfect for aerospace, medical, and complex mold components

Capable of machining undercuts and compound angles in one setup

Additional Equipment:

3 four-axis machining centers

3 three-axis vertical machining centers

Full suite of measurement instruments including CMMs, projectors, and roughness testers

Engineering & DFM Support

Engineering involvement begins before production.

Our team reviews every RFQ for manufacturability, tolerance stack-up, and material suitability — reducing risk and improving throughput.

Engineering Strengths:

DFM/DFA consulting before machining

CAD/CAM programming using Mastercam & UG NX

3D simulation for toolpath optimization and collision avoidance

Custom fixture design for complex geometries

Rapid feedback during prototyping and pilot runs

Quality & Process Capability

We combine skilled technicians with advanced systems to achieve consistent results.

ISO 9001 & IATF 16949 certified quality system

Statistical process control (SPC) and traceable inspection data

In-process measurement with digital probes and coordinate systems

Tool life management and automated offset correction

Batch documentation and first-article inspection (FAI) for new parts

Why Choose CNMP

At CNMP, we go beyond precision machining — we deliver reliability, transparency, and technical excellence at every stage of your project.

Engineering Expertise You Can Rely On

Our team of experienced engineers provides full technical support from design review to production optimization.

We analyze drawings, recommend suitable materials, and ensure manufacturability without compromising performance.

Highlights:

- DFM (Design for Manufacturability) support;

- Rapid feedback within 24 hours;

- Professional drawing and tolerance review;

Advanced Manufacturing Equipment

We operate a full range of CNC turning, milling, and 5-axis machining centers, supported by CMM inspection and precision measuring tools.

This allows us to maintain repeatable accuracy even for complex geometries.

Highlights:

- 3–5 axis machining centers (±0.005 mm)

- Automated tool calibration systems

- Full in-process quality monitoring

Certified Quality Assurance

Our production follows ISO 9001 and IATF 16949 management systems.

Every part is tracked through a digital quality record, ensuring full traceability and process consistency.

Highlights:

- Material and batch traceability

- 100% inspection for key dimensions

- CMM and surface roughness verification

Global Project Experience

CNMP partners with clients in over 30 countries — from automotive and aerospace to medical and energy sectors.

We understand each industry’s standards and compliance requirements.

Highlights:

- Multi-industry project experience

- Familiarity with export documentation and packaging

- Long-term global partnerships

Reliable Communication & On-Time Delivery

Time and trust matter. Our bilingual project managers ensure smooth communication and fast response through every phase of cooperation.

Highlights:

- Dedicated project follow-up

- Weekly production updates

- On-time delivery commitment