5 Axis CNC Machining Services: The Insider’s Guide to High-Precision Manufacturing in China

Introduction: The “Precision Paradox” in Modern Manufacturing

In the high-stakes world of custom manufacturing, precision is not merely a metric on a blueprint; it is the difference between a successful product launch and a catastrophic failure. As an engineer or procurement manager tasked with sourcing complex, non-standard components, you are likely living through what we call the “Precision Paradox.”

The paradox is simple yet frustrating: Modern engineering designs are becoming exponentially more complex—featuring organic geometries, topological optimization for weight reduction, and intricate undercuts—yet the pressure to reduce costs and lead times has never been higher. You are expected to deliver aerospace-grade quality at consumer-grade speeds.

If you have ever sourced parts from overseas, you might be familiar with the “3 AM panic.” You wake up worrying if the batch of impellers arriving next week will actually fit the assembly. You replay the nightmare of “stack-up errors” caused by a supplier who tried to cut corners by using multiple setups on a cheap 3-axis machine instead of the 5 axis cnc machining services you actually needed. You worry about communication gaps, “quality fade” over time, and whether your proprietary designs are truly secure.

This guide is written to end that panic.

As a premier provider of 5 axis cnc machining services in China, we are pulling back the curtain. We aren’t just selling a service; we are offering an education. Over the next few thousand words, we will dismantle the myths surrounding Chinese manufacturing, explain the deep technical mechanics of high-end 5-axis technology, and provide you with a battle-tested roadmap to sourcing complex parts with absolute confidence.

Whether you are building robotic end-effectors, medical implants, or turbine components, this is the only guide you will ever need to navigate the world of high-precision 5 axis cnc machining services.

Part 1: Deep Dive: The Mechanics of True 5-Axis Precision

To make an informed buying decision, you need to understand the machinery at a granular level. Why exactly are 5 axis cnc machining services considered the “gold standard” of the industry? It is not just about having “more axes”—it is about kinematics and rigidity.

The Limitation of the Status Quo (3-Axis)

In traditional 3-axis machining, the cutting tool moves along three linear planes: X (left-right), Y (forward-backward), and Z (up-down). This works perfectly for prismatic parts—think simple brackets or flat plates.

However, the moment your design requires machining on the sides, the process breaks down. The operator must stop the machine, open the door, unclamp the part, clean the fixture, flip the part, and re-clamp it.

Here lies the enemy of precision: Stack-Up Error.

Even the most skilled machinist cannot re-fixture a part with zero error. A misalignment of just 0.01mm in the second setup, added to 0.01mm in the third, results in a final part that is geometrically imperfect. For an aerospace valve requiring a positional tolerance of 0.05mm across opposing faces, this method is a recipe for disaster.

The 5-Axis Revolution: “Done-in-One”

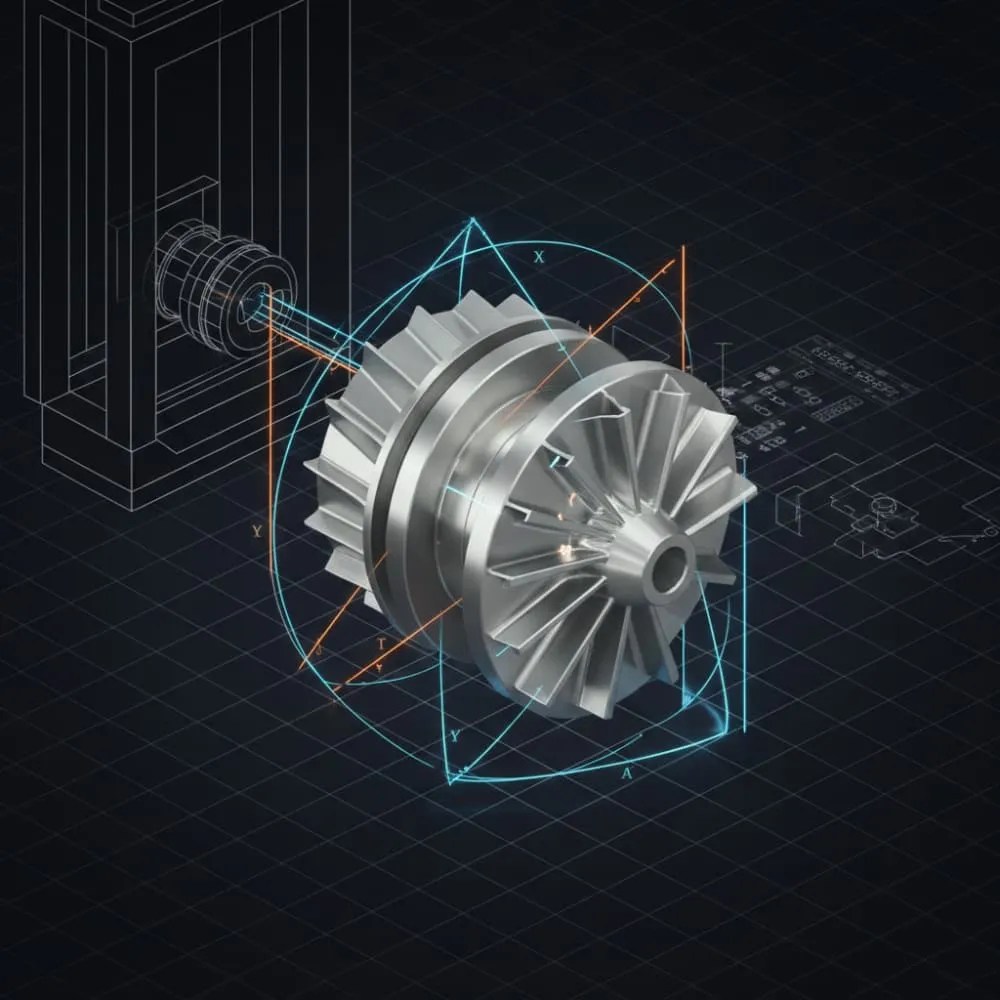

Professional 5 axis cnc machining services utilize advanced machinery where the cutting action is not limited to linear movements. The machine introduces two rotary axes (A, B, or C) that work in concert with X, Y, and Z.

This means the cutting tool can approach the workpiece from virtually any vector (except the bottom clamping face). A raw block of titanium or aluminum can be transformed into a complex, multi-faceted geometry in a single setup. This is often referred to in the industry as the “Done-in-One” philosophy.

By eliminating manual re-fixturing, we maintain a single “Work Coordinate System” (G54) throughout the entire process. The result? Unrivaled relative accuracy between features.

Machine Configurations: Trunnion vs. Swivel Head

Not all 5 axis cnc machining services utilize the same hardware. Understanding the difference can help you assess a supplier’s capability:

- Trunnion Style (Table-Table): The work table tilts (A-axis) and rotates (C-axis). This is excellent for smaller, heavier parts because the table is rigid. It is the preferred configuration for medical implants and small impellers.

- Swivel Head Style (Head-Table): The spindle head tilts (B-axis) while the table rotates (C-axis). This allows for machining much larger and heavier parts that would differ from tilting a table. This is common in large aerospace structural components and automotive molds.

A competent supplier offering 5 axis cnc machining services should be able to explain which machine configuration is best suited for your specific project.

Part 2: Simultaneous 5-Axis vs. 3+2 Axis (Indexed)

This is the most critical distinction in the entire sourcing process, and unfortunately, it is where many buyers get misled. When a supplier claims to offer 5 axis cnc machining services, you must ask: “Is it Simultaneous or Indexed?”

3+2 Axis Machining (Positional 5-Axis)

In this process, the machine uses its 4th and 5th axes to rotate the part to a fixed angle, locks the axes in place, and then performs standard 3-axis machining.

- Best Use Case: Parts with holes on angled surfaces, or deep pockets where tilting the part allows for a shorter, more rigid tool.

- Limitation: It cannot machine a continuous curve that wraps around the part.

Simultaneous 5-Axis Machining

This is the “true” form of 5 axis cnc machining services. The cutting tool (X, Y, Z) and the rotary axes (A/B, C) move at the exact same time. The computer is calculating thousands of points per second to keep the tool moving smoothly along a complex 3D contour.

- Best Use Case: Turbine blades, centrifugal impellers, anatomical bone plates, and complex molds.

- The Technical Edge: This requires advanced features like TCPC (Tool Center Point Control), which dynamically adjusts the machine’s linear axes to compensate for the rotation of the part, ensuring the tooltip stays exactly where it needs to be.

Expert Insight: If your supplier cannot explain TCPC or does not use high-end CAM software like Hypermill or Mastercam, they likely do not possess true simultaneous 5 axis cnc machining services capabilities.

Part 3: The Business Case: ROI and Total Cost of Ownership

Why should a procurement manager approve a quote for 5 axis cnc machining services when a 3-axis quote is 20% cheaper on paper? Because the “sticker price” is deceptive. You need to look at the Total Cost of Production.

1. The Hidden Cost of Fixtures

To machine a complex housing on a 3-axis machine might require 6 different setups. That means designing, manufacturing, and storing 6 custom fixtures. These fixtures cost money and take weeks to build. With 5 axis cnc machining services, we often use a single, standard dovetail fixture or a centering vise. The upfront tooling cost is slashed, and lead time is reduced by weeks.

2. Tool Life and Surface Finish

In 3-axis machining, reaching the bottom of a deep cavity requires a long cutting tool. Long tools vibrate. This vibration (“chatter”) ruins surface finishes and kills tool life.

In 5 axis cnc machining services, we tilt the tool (or the table) to allow the use of a stubby, short cutter. Short tools are rigid. They produce a mirror-like finish (Ra 0.8μm or better) straight off the machine. This eliminates the need for expensive, inconsistent manual polishing—saving you labor costs.

3. Yield Rate and Risk

With 6 setups on a 3-axis machine, there are 6 opportunities for human error. If the operator loads the part slightly crooked on Setup #4, the part is scrap.

5 axis cnc machining services drastically reduce human intervention. Once the “Cycle Start” button is pressed, the machine handles the complexity. The yield rate skyrockets, ensuring you get your full order quantity on time.

Decision Matrix:

- Simple Bracket: Stick to 3-Axis.

- Angled Holes: Use 3+2 Axis.

- Organic Shapes / Tight Geometric Tolerances: You must use Simultaneous 5 axis cnc machining services.

Part 4: The China Advantage in the Global Supply Chain

The narrative around “Made in China” has shifted from “cheap labor” to “integrated ecosystems.” Leading providers of 5 axis cnc machining services in China, particularly in hubs like Shenzhen, Dongguan, and Suzhou, have evolved into high-tech precision centers.

Tier-1 Hardware Availability

Walk into our workshop, and you won’t see outdated machinery. You will see rows of Hermle (Germany), DMG MORI (Japan/Germany), and Mazak (Japan) 5-axis centers. We combine this world-class hardware with rigorous Chinese work ethics to provide capacity that Western shops struggle to match.

The Speed of the Ecosystem

The real superpower of Chinese manufacturing is the supply chain density.

In the US or Europe, if you need a part machined, then heat-treated, then anodized, and finally laser-marked, you might be shipping it to four different vendors across three states. Each step adds a week of lead time.

In our industrial ecosystem, the heat treatment facility is down the street. The anodizing plant is a 10-minute drive. We can source raw aerospace-grade Aluminum 7075 or Titanium TC4 within 24 hours. This integration allows 5 axis cnc machining services in China to offer lead times of 7-10 days for parts that take 6 weeks elsewhere.

The “Ghost Shift” Efficiency

While labor costs have risen, efficiency has risen faster. We utilize pallet-changing systems and automation to run “lights-out” manufacturing (the Ghost Shift) overnight. Your parts are being machined while the world sleeps, driving down the unit cost for low-to-mid volume production runs.

Part 5: Material Mastery in 5-Axis Machining

The rigidity and vector control of 5 axis cnc machining services unlock the ability to process the world’s most difficult materials.

Titanium (Grade 5 / TC4)

The standard for aerospace. Titanium has low thermal conductivity, meaning heat stays in the tool rather than the chip. Our 5-axis strategy allows us to engage the tool at optimal angles to spread tool wear and dissipate heat, preventing work-hardening.

Inconel & Hastelloy (Superalloys)

Used in jet engines and oil & gas. These are notorious for destroying tools. The stability of our 5-axis machines allows for “Trochoidal Milling” (Dynamic Milling), a strategy that maintains constant tool load, making the machining of superalloys feasible and cost-effective.

Engineering Plastics (PEEK, Ultem, Torlon)

For medical implants and insulators. The challenge here is deformation and melting. 5 axis cnc machining services allow for high feed rates (removing heat with the chip) and single-setup completion, which prevents the plastic from relaxing and warping between multiple setups.

Part 6: Design for Manufacturing (DFM) Masterclass

To get the most out of 5 axis cnc machining services, your design should align with the process. Here are insider tips from our engineering team:

- Avoid Deep, Sharp Corners: The cutting tool is round. Asking for a sharp internal corner requires EDM (Electrical Discharge Machining), which adds cost. Add a fillet radius slightly larger than the tool radius to allow the tool to move continuously without stopping.

- Standardize Radii: If possible, use the same floor radii across the part. This minimizes tool changes.

- Consider Tool Reach: Even in 5 axis cnc machining services, there are physical limits. A good rule of thumb is a depth-to-diameter ratio of 3:1 for standard tools, and up to 10:1 for specialized tooling. Beyond that, vibration becomes an issue.

- Workholding Zones: Remember, the machine needs to hold the part somewhere. Design in a “dovetail” or a sacrifice layer on the bottom of the part that we can clamp onto, which will be machined off in a final operation.

Part 7: Quality Assurance and E-A-T (Expertise, Authoritativeness, Trust)

How do you trust a supplier thousands of miles away? You look for the “Trust Signals” that define professional 5 axis cnc machining services.

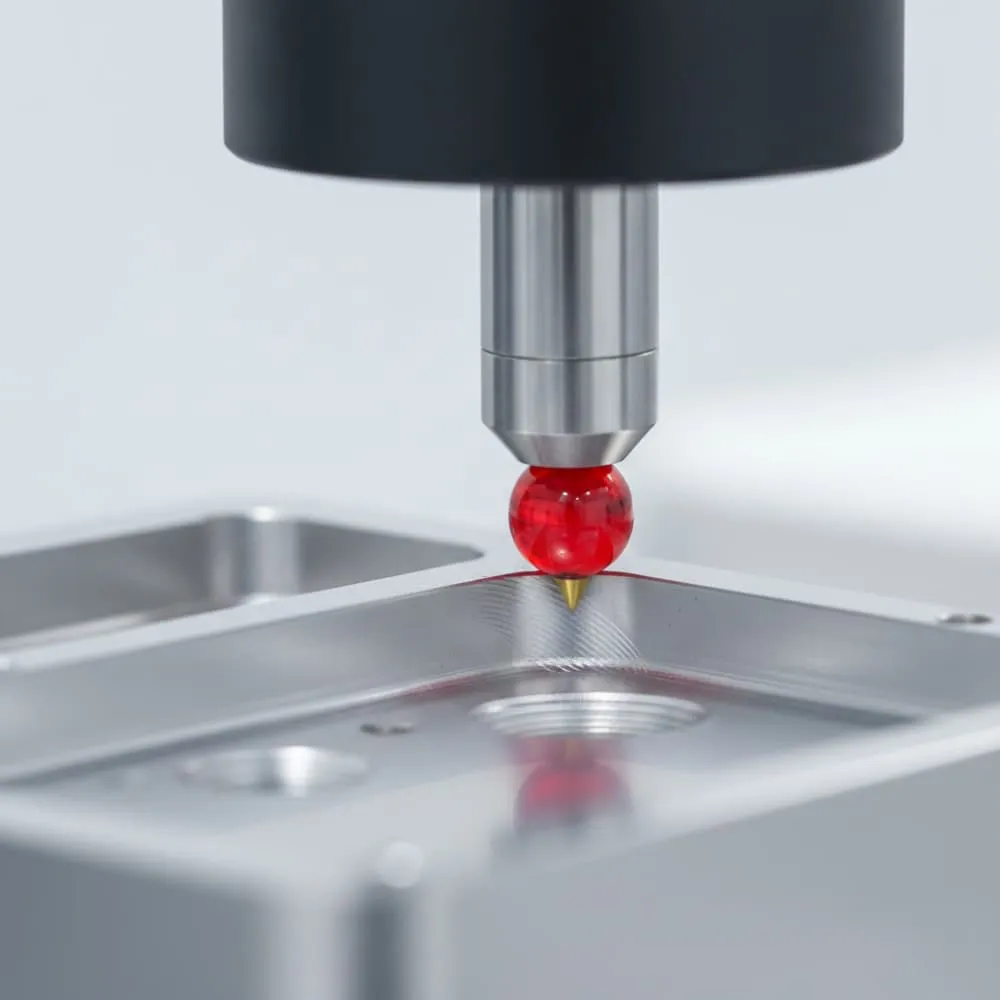

In-Process Verification (Renishaw Probing)

Quality is not an afterthought; it is part of the cycle. We use high-precision Renishaw probes integrated into the machine spindle. Before the part is even unclamped, the probe measures critical dimensions and datums. If a deviation is detected (due to tool wear or thermal expansion), the machine automatically updates the tool offset and re-cuts the feature. This is closed-loop quality control.

The CMM Final Exam

Once the part leaves the machine, it goes to the climate-controlled Quality Lab. Here, a CMM (Coordinate Measuring Machine) validates the complex 3D geometry against your original CAD model. We verify tolerances down to ±0.005mm.

Traceability

We provide a comprehensive data package with every shipment:

- Material Test Reports (Mill Certificates)

- Dimensional Inspection Reports

- Surface Finish Reports

- Heat Treatment / Plating Certificates

We are certified to ISO 9001 (General Quality) and ISO 13485 (Medical Devices), ensuring our processes meet global standards.

Part 8: The Buyer’s Ultimate Checklist

Before you send that RFQ for 5 axis cnc machining services, vet your supplier against this list. A “No” to any of these is a red flag.

- True Capability Check: Do they have simultaneous 5-axis machines, or only 3+2? Ask for a video of their machine cutting a test part.

- Software Stack: Do they use licensed, high-end CAM software (Mastercam, Hypermill, Siemens NX)? Pirated or low-end software cannot safely run complex 5-axis paths.

- IP Protection: Will they sign an enforceable NDA (Non-Disclosure Agreement) before you send files? (We always do).

- English Engineering: Do you have direct access to a project engineer who speaks English, or are you filtered through a non-technical salesperson?

- Inspection Equipment: Do they own a CMM? Ask for the brand and model.

- One-Stop Service: Can they handle the anodizing, plating, or laser marking in-house or through certified partners?

FAQ: Your Burning Questions Answered

Q: Is 5 axis cnc machining services always more expensive?

A: Not necessarily. For simple parts, yes. But for complex parts that would require 5+ setups on a 3-axis machine, 5 axis cnc machining services are often cheaper due to the dramatic reduction in labor time, fixture costs, and scrap rates.

Q: What file formats are best for 5-axis quotes?

A: We need a neutral 3D format like STEP (.stp) or IGES (.igs). Native files (SolidWorks, Catia) are also acceptable. Crucial: Always accompany the 3D file with a 2D PDF drawing that calls out tight tolerances, threads, and surface finish requirements (e.g., specific Ra values).

Q: How do you handle IP security for overseas clients?

A: We treat your IP as our own. We operate on a strict “Need to Know” basis. Your data is stored on secure, local servers protected by enterprise-grade firewalls. Shop floor drawings are often coded to anonymize the end-application. We are happy to sign your company’s standard NDA.

Q: What is the typical lead time?

A: Thanks to our agile supply chain, we typically ship standard 5-axis prototypes within 7–10 business days. Production runs are scheduled based on volume, but generally 2-3 weeks.

Q: Can you do “High-Mix, Low-Volume”?

A: Absolutely. This is the sweet spot for 5 axis cnc machining services. The reduced setup time makes it economically viable to run batches as small as 1 to 50 units.

Conclusion: The Future is Precision

The era of simple manufacturing is fading. As your designs push the limits of physics—lighter, stronger, more efficient—your manufacturing partner must push the limits of technology.

5 axis cnc machining services represent the pinnacle of subtractive manufacturing. They offer the geometric freedom to innovate without being shackled by “manufacturability constraints.”

By choosing a partner in China who combines this advanced technology with speed, integrity, and cost-efficiency, you are not just buying parts; you are gaining a competitive edge in the global market. You are securing a supply chain that can scale with your success.

Don’t let legacy manufacturing hold back your innovation.

Ready to Experience True Precision?

Stop worrying about stack-up errors and missed deadlines. Upload your 3D models today for a comprehensive Free DFM Review and an instant quotation. Let our engineering team prove why we are the trusted choice for 5 axis cnc machining services.